Dec . 11, 2024 20:19 Back to list

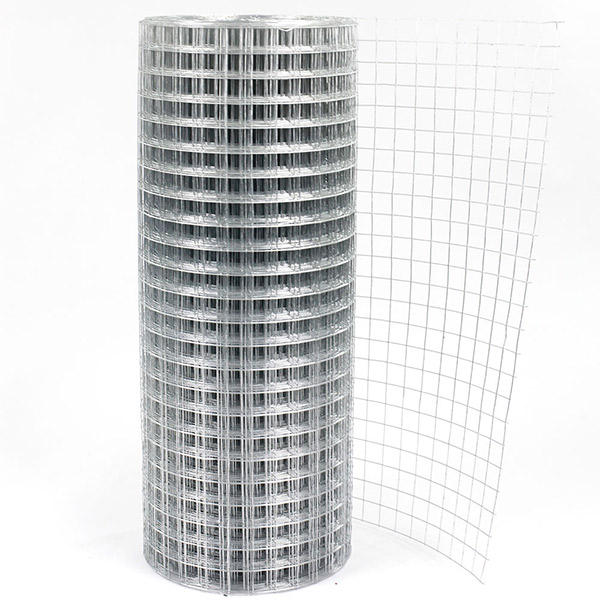

brc welded wire mesh

Understanding BRC Welded Wire Mesh Applications and Benefits

BRC welded wire mesh, often referred to simply as welded wire mesh, is a reliable and versatile product widely used in various construction and industrial applications. The acronym BRC stands for British Reinforcement Concrete, highlighting its origins and design for use in reinforced concrete structures. This article will delve into the characteristics, manufacturing process, applications, and benefits of BRC welded wire mesh, shedding light on why it is an essential material in modern construction.

What is BRC Welded Wire Mesh?

BRC welded wire mesh consists of a grid of steel wires that are welded together at their intersections. These wires are arranged in a predetermined spacing and come in various diameters, depending on the specific requirements of the project. The mesh sheets can be produced in varying sizes and can be custom-made to meet specific design criteria. The most common type of wire used is high-quality carbon steel that offers excellent strength and durability.

Manufacturing Process

The manufacturing of BRC welded wire mesh involves several key steps

1. Wire Production The first step is to produce or source the steel wire. The wire is typically cold-drawn to achieve the desired diameter and mechanical properties.

2. Welding The wires are arranged in a grid pattern and welded at their intersections using an automated welding process. This ensures high-quality joints that enhance the mesh’s structural integrity.

3. Cutting and Packaging After welding, the mesh sheets are cut to size based on customer specifications. They are then packaged and prepared for transportation and delivery.

Applications of BRC Welded Wire Mesh

BRC welded wire mesh is primarily used in the construction industry for several applications

2. Fencing The mesh can be used as a fencing solution for properties, gardens, and agricultural land, offering security and demarcation.

brc welded wire mesh

3. Construction of Retaining Walls BRC mesh is employed in the construction of retaining walls to improve load-bearing capabilities and prevent soil erosion.

4. Industrial Applications The mesh is commonly utilized in industrial settings for creating partitions, machine guards, and shelving units.

5. Drainage Solutions It is also used in drainage systems, helping to stabilize soil and prevent the collapse of drainage channels.

Benefits of BRC Welded Wire Mesh

The popularity of BRC welded wire mesh in the construction industry can be attributed to several advantages

1. Strength and Durability The welding process produces a strong mesh that can withstand significant loads, making it ideal for various structural applications.

2. Cost-Effectiveness Compared to traditional reinforcement methods, BRC welded wire mesh is often more affordable, both in terms of materials and labor, leading to overall savings on projects.

3. Ease of Installation The mesh is lightweight and easy to handle, allowing for quicker installation processes. This efficiency can lead to faster project completion times.

4. Versatility BRC welded wire mesh can be customized for different applications, with varying wire diameters and spacing options to suit specific project needs.

5. Corrosion Resistance When coated with protective materials or galvanized, the mesh can resist corrosion, extending its lifespan and effectiveness in various environments.

Conclusion

BRC welded wire mesh is an indispensable material in the modern construction landscape. Its combination of strength, cost-effectiveness, and versatility makes it an ideal choice for numerous applications, ranging from concrete reinforcement to fencing solutions. As the construction industry continues to evolve, the demand for robust and efficient materials like BRC welded wire mesh will likely only grow, making it a staple in building projects worldwide. Whether you are a contractor, architect, or manufacturer, understanding the benefits and applications of BRC welded wire mesh can help you make informed decisions for your construction needs.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025