Dec . 10, 2024 07:11 Back to list

black nail wire manufacturers

The Importance of Quality in Black Nail Wire Manufacturing

In the world of construction and manufacturing, black nail wire plays a critical role. It is used extensively in various applications, from building frameworks to simple household repairs. However, the effectiveness of this vital component largely depends on the quality of the wire produced by manufacturers. This article delves into the process of black nail wire manufacturing, the significance of quality, and what to look for in a reliable black nail wire manufacturer.

Understanding Black Nail Wire

Black nail wire is typically made from low-carbon steel wire, which gives it strength, flexibility, and durability. The term black refers to the wire’s finish, which is created through a process known as oil coating. This process not only provides a protective layer that prevents corrosion but also offers a non-slip surface for better gripping during installation.

Black nail wire comes in various gauges, depending on its intended use. Thicker gauges are often used for heavy-duty applications, like construction staples or framing, while lighter gauges may be more suitable for tasks such as crafting or general repairs. The versatility of black nail wire makes it an essential item in any toolbox or workshop.

The Manufacturing Process

The production of black nail wire involves several steps, each critical to ensuring the quality of the final product. The journey begins with selecting high-quality raw materials, usually drawn from reliable steel suppliers. The wire is then subjected to a drawing process, where it is pulled through a series of dies to achieve the desired thickness and tensile strength.

Once the drawing is complete, the wire undergoes a hardening and tempering process. This involves heating the wire to a specific temperature and then cooling it rapidly to enhance its strength and elasticity. The final step in the manufacturing process is the application of the oil coating, which not only provides the characteristic black finish but also protects the wire from rust and other forms of corrosion.

The Significance of Quality

black nail wire manufacturers

Quality is paramount in black nail wire manufacturing for several reasons. First and foremost, inferior wire can lead to structural failures, which can be dangerous and costly. A weak nail wire may bend, break, or corrode easily, compromising the integrity of the structure it is meant to support.

Moreover, high-quality black nail wire typically has better pull-out resistance and holding power, making it suitable for heavy-duty applications. For manufacturers and contractors, using subpar materials can result in costly project delays and damage control due to warranty claims.

Additionally, consistent quality in production is essential to maintain the trust of customers. Reputable manufacturers often adhere to strict quality control measures and industry standards, ensuring that their products meet or exceed the expectations of their clients.

Choosing the Right Manufacturer

When looking for a reliable black nail wire manufacturer, there are several factors to consider. Firstly, it's essential to assess their production capabilities. A manufacturer with advanced technology and a skilled workforce is more likely to produce high-quality products consistently.

Secondly, certifications and industry standards should not be overlooked. Manufacturers that comply with internationally recognized quality standards, such as ISO certifications, demonstrate their commitment to maintaining excellence in their products.

Lastly, customer reviews and testimonials can provide valuable insights into a manufacturer’s reputation. Engaging with previous clients or checking online feedback platforms can help you gauge their reliability and the quality of their wire products.

Conclusion

Black nail wire is a fundamental component in many industries, and its quality can make a significant difference in the success of construction and manufacturing projects. Choosing a reputable manufacturer who prioritizes quality at every stage of the production process is crucial. By understanding the manufacturing process, recognizing the importance of quality, and knowing what to look for in a supplier, businesses can ensure they receive the best black nail wire available, ultimately contributing to the safety and longevity of their projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

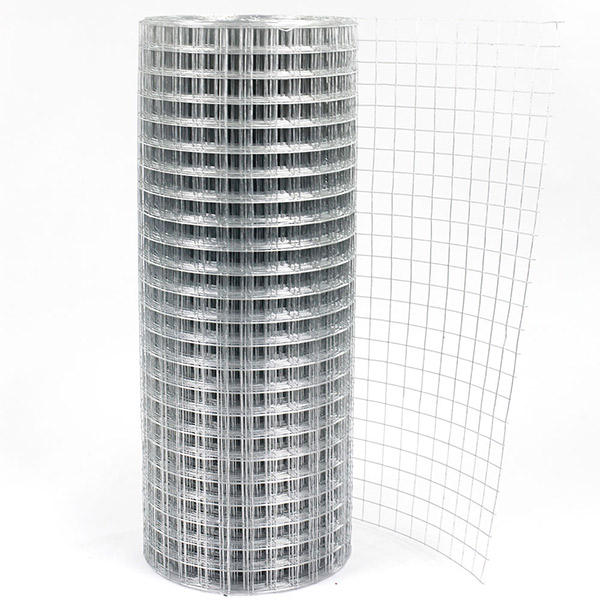

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025