Dec . 10, 2024 11:27 Back to list

black binding wire manufacturer

The Importance of Black Binding Wire in Manufacturing and Construction

In the realm of manufacturing and construction, binding materials play a crucial role in ensuring the structural integrity and cohesion of various products. One such essential component is black binding wire, a versatile and durable solution that caters to a wide range of applications. This article will explore the significance of black binding wire, its manufacturing process, and the benefits that it offers.

What is Black Binding Wire?

Black binding wire is a type of steel wire that is coated with a black oxide finish. This coating provides added protection against corrosion and enhances the wire's durability. Typically made from low-carbon steel, black binding wire is known for its strength, flexibility, and tensile properties, making it an ideal choice for various applications.

Manufacturing Process

The production of black binding wire begins with the selection of high-quality raw materials. The steel is first drawn into wire, undergoing a series of processes that refine its diameter and increase its strength. After being drawn, the wire is then subjected to processes like annealing, which enhances its ductility, making it easier to manipulate during use.

Once the wire reaches the desired specifications, it undergoes a black oxide treatment. This treatment not only provides an aesthetic appeal but also protects the wire from rust and other environmental factors. Finally, the wire is cut into various lengths and is typically wound into coils for easy handling and transport.

Applications of Black Binding Wire

Black binding wire is widely used across different industries, including construction, agriculture, and manufacturing. In construction, it plays a pivotal role in reinforcing concrete structures, tying rebar together, and securing building materials. Its strength ensures that structures can withstand various loads and stresses, contributing to their overall stability.

black binding wire manufacturer

In agriculture, black binding wire is often used for fencing and supporting plants, offering a reliable solution for farmers and gardeners looking to protect their crops or delineate property boundaries. Additionally, in the manufacturing sector, it serves as a critical component for assembling products and securing items during shipping and storage.

Advantages of Black Binding Wire

1. Durability The black oxide finish protects the wire from corrosion and other environmental impacts, prolonging its lifespan and ensuring reliability in various settings.

2. Flexibility Its ductility allows for easy manipulation, making it suitable for different applications without the risk of breakage or snapping.

3. Cost-Effectiveness Black binding wire is an economical choice for many industries, providing high strength at a relatively low cost, which is essential for budget-conscious projects.

4. Versatility It can be used for a multitude of applications, from construction to agriculture, and can be easily adapted for various uses depending on the needs of the project.

5. Easy Handling Available in coils, black binding wire is convenient to store and transport, making it a practical choice for contractors and manufacturers alike.

Conclusion

As a manufacturer of black binding wire, it is vital to understand its significance and applications in the market. With its strong properties, versatility, and cost-effectiveness, black binding wire is an indispensable component in construction and manufacturing. As industries continue to evolve and innovate, the demand for reliable binding materials like black binding wire is expected to grow, highlighting its importance in supporting various structural and operational needs. Investing in quality black binding wire not only enhances productivity but also contributes to the durability and integrity of the projects it supports.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

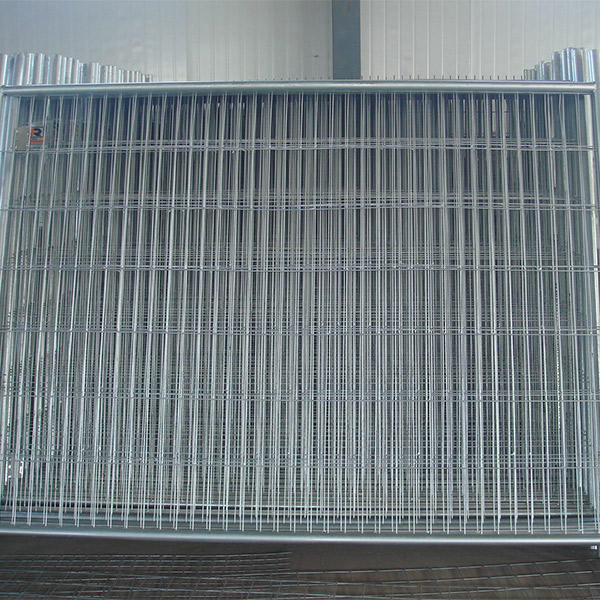

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025