Nov . 11, 2024 16:59 Back to list

black binding wire factories

Black Binding Wire Factories A Comprehensive Overview

In the evolving landscape of manufacturing, black binding wire has emerged as a crucial component across various industries, particularly in construction, agriculture, and packaging. This versatile wire, primarily made of low carbon steel, is utilized for its strength, durability, and flexibility. Black binding wire factories play an essential role in producing this indispensable material, meeting the demands of both local and international markets.

Understanding Black Binding Wire

Black binding wire, also known as black annealed wire, is characterized by its dark, smooth finish that results from the manufacturing process. Typically, this wire is produced in gauges ranging from 0.5 mm to 5 mm and comes in different coil sizes to cater to specific applications. Its applications are extensive from securing building materials in construction sites to bundling agricultural products and reinforcing concrete structures. The properties of black binding wire, including its resistance to rust and corrosion, make it ideal for outdoor use, where exposure to the elements can be a concern.

The Manufacturing Process

The production of black binding wire involves several steps, beginning with the selection of high-quality steel. The manufacturing process includes wire drawing, annealing, and coating. Initially, steel rods are drawn through a series of dies to reduce their diameter. This is followed by the annealing process, where the wire is heated in a controlled environment, allowing it to gain flexibility and a dark finish. Finally, the wire is wound into coils for packaging and distribution.

Black binding wire factories are equipped with advanced machinery that ensures precision in production. Automation technology is widely adopted to enhance efficiency and reduce human error, helping to maintain consistent quality. Quality control is integral to the production process, ensuring that the wire meets industry standards and customer specifications.

Market Demand and Applications

black binding wire factories

The demand for black binding wire is influenced by various sectors. In construction, the wire is essential for tying concrete structures and scaffolding. The agricultural sector uses it for bundling crops and securing plants, while packaging industries rely on black binding wire for its reliable binding solutions. In addition to these applications, black binding wire is also utilized in the manufacturing of furniture and decorative items.

As urbanization continues to rise and infrastructure projects expand globally, the market for black binding wire is expected to grow. Factories must be adaptable, responding to trends such as increased demand for environmentally friendly products and innovations in production techniques.

Challenges Facing Factories

Black binding wire factories face several challenges in the current market landscape. Fluctuations in raw material prices can significantly impact production costs. Additionally, the increased focus on sustainability compels manufacturers to explore eco-friendly alternatives and processes. Compliance with environmental regulations is becoming more stringent, and factories must invest in sustainable practices to minimize their carbon footprint.

Furthermore, competition is fierce in the binding wire industry, with numerous players vying for market share. To remain competitive, factories must focus on innovation, quality, and customer service, ensuring that they can meet the evolving needs of their clients.

Conclusion

The role of black binding wire factories is indispensable in today’s manufacturing environment. As industries rely increasingly on this versatile material, the factories that produce it must be prepared to adapt to changing market dynamics. By focusing on quality, sustainability, and efficiency, these factories can continue to thrive, contributing significantly to various sectors. With the right strategies in place, the future of black binding wire production looks promising, underpinning the growth of economies worldwide.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

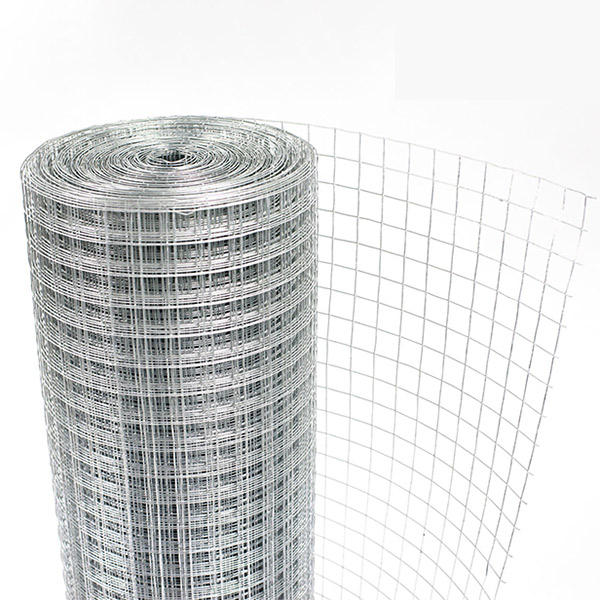

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025