Nov . 06, 2024 11:05 Back to list

black annealing furnace for binding wire factories

Enhancing Efficiency in Binding Wire Factories with Black Annealing Furnaces

In the manufacturing sector, particularly in the production of binding wires, the annealing process plays a crucial role in improving the quality and performance of the end product. A black annealing furnace serves as a pivotal component in this process, especially for factories focused on producing binding wires. This specialized furnace not only enhances the mechanical properties of the wire but also contributes to overall operational efficiency.

The primary purpose of a black annealing furnace is to heat wire coils to a specific temperature in a controlled atmosphere, allowing for the desired metallurgical properties to develop. Binding wires, which are widely used in construction, fencing, and various industrial applications, require specific attributes such as ductility, strength, and resistance to corrosion. The annealing process, when executed correctly, can significantly enhance these properties, ensuring that the final product meets industry standards and customer expectations.

One of the significant advantages of using a black annealing furnace is its ability to operate in a reducing atmosphere, typically using gases such as nitrogen or a mixture of gases. This feature prevents oxidation of the wire during the heating process, resulting in a clean finish that is crucial for binding wires. The black color of the wire, which is a result of the annealing process, offers not only aesthetic appeal but also reduces the risk of corrosion, thereby prolonging the lifespan of the product.

black annealing furnace for binding wire factories

Furthermore, modern black annealing furnaces are equipped with advanced technology that allows for precise temperature control and monitoring. This capability ensures uniform heating, which is essential for achieving consistent wire properties throughout the coil. The improved technology also enables factories to optimize energy consumption, thus reducing operational costs. By minimizing energy usage while maximizing output quality, manufacturers can enhance their competitiveness in the market.

In addition to operational efficiency, black annealing furnaces contribute to sustainability in binding wire production. The reduction in waste and the ability to recycle heat generated during the process align with global sustainability goals. As industries increasingly focus on reducing their carbon footprint, adopting energy-efficient manufacturing processes becomes imperative. The integration of black annealing furnaces is a step toward greener manufacturing practices.

Lastly, when selecting a black annealing furnace for a binding wire factory, it is essential to consider factors such as furnace capacity, energy efficiency, and technological features. Investing in high-quality furnaces that incorporate the latest advancements in thermal processing can yield significant long-term benefits. As the industry continues to evolve, staying abreast of technological developments will allow binding wire manufacturers to remain competitive and responsive to market demands.

In conclusion, black annealing furnaces are integral to the operation of binding wire factories, enhancing wire quality while promoting operational efficiency and sustainability. By harnessing the capabilities of these furnaces, manufacturers can ensure that their products not only meet but exceed market expectations, driving growth and success in an increasingly competitive landscape. As the demand for high-quality binding wires continues to grow, so too will the importance of advanced annealing technologies in the manufacturing process.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

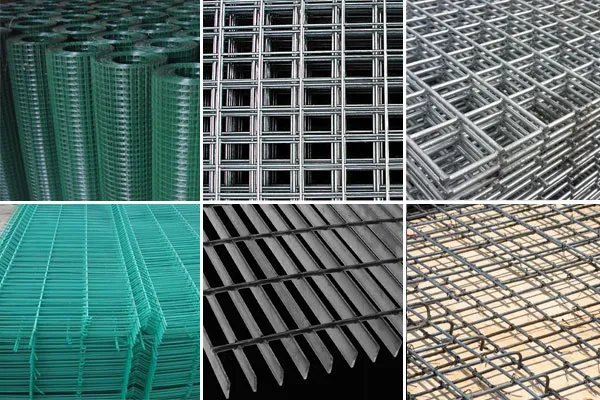

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025