Dec . 07, 2024 09:34 Back to list

black annealed wire specification factory

Understanding Black Annealed Wire Specifications and Manufacturing Process

Black annealed wire is a commonly used material in various industries due to its unique properties and versatility. It is primarily manufactured from low carbon steel and is subjected to a specific annealing process that enhances its malleability and strength. This article delves into the specifications of black annealed wire and the processes involved in its production, shedding light on its importance in different applications.

Specifications of Black Annealed Wire

The specifications of black annealed wire vary based on the intended use and the standards set by manufacturing entities. Generally, black annealed wire is available in different diameters, ranging from 0.2 mm to 5 mm or more, depending on the production requirements. The material is produced in coils or spools, with standard weights that typically range from 50 kg to 500 kg per coil.

The tensile strength of black annealed wire is a critical specification, as it indicates the wire's ability to withstand pulling forces. Typically, the tensile strength ranges from 300 MPa to 700 MPa, ensuring that the wire can maintain integrity under tension. Another vital specification is its elongation rate, which usually falls between 10% to 30%. This elongation property is important in applications requiring ductility and flexibility, allowing the wire to be shaped without breaking.

Black annealed wire also undergoes surface treatment to achieve its characteristic dark finish. This treatment not only enhances its aesthetic appeal but also provides additional protection against corrosion, making it suitable for outdoor applications.

Manufacturing Process

The production of black annealed wire begins with the selection of high-quality low carbon steel. After the steel is processed into wire rods, it undergoes a heat treatment known as annealing. This process involves heating the wire to a specific temperature and then allowing it to cool slowly. The annealing process softens the wire, improves its ductility, and reduces internal stresses that may have formed during the drawing process.

black annealed wire specification factory

Once the annealing is completed, the wire is drawn to the specified diameter using a series of dies. This process not only shapes the wire but also increases its tensile strength through work hardening. After drawing, the wire is subjected to a surface treatment that involves coating it with a layer of lubricating oil, enhancing its corrosion resistance and easing handling during further processing.

Quality control is an essential aspect of black annealed wire production. Manufacturers conduct rigorous testing to ensure that the wire meets the specified standards for tensile strength, elongation, and surface finish. This quality assurance process ensures that the wire can perform effectively in its intended applications, whether in construction, fencing, or manufacturing.

Applications

Black annealed wire is utilized in a wide range of applications due to its favorable mechanical properties. In the construction industry, it is commonly used as binding wire for reinforcing bars (rebar) in concrete structures. Its flexibility allows for easy tying of rebar, ensuring structural integrity.

In agricultural settings, black annealed wire serves various functions, including fencing for livestock and trellising for crops. The wire's resistance to rust and corrosion makes it an ideal choice for outdoor environments.

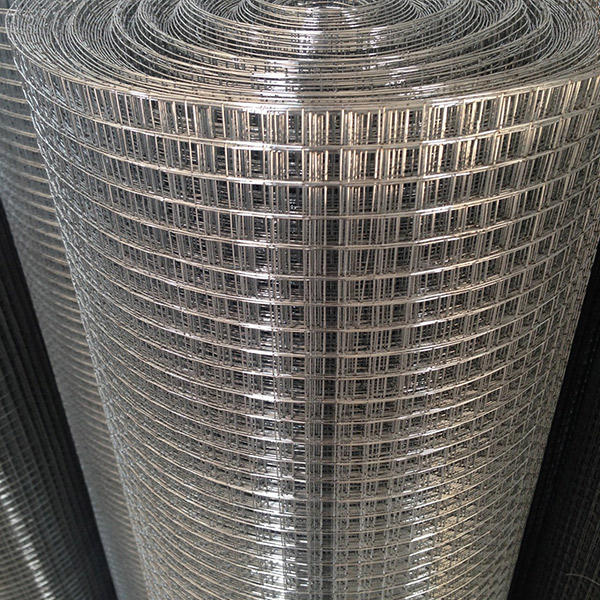

Additionally, black annealed wire is also employed in the production of wire mesh, spring coils, and other industrial applications where strength and flexibility are paramount.

Conclusion

In conclusion, black annealed wire stands out as a critical material with diverse applications across several industries. Its unique specifications, including tensile strength and ductility, combined with a meticulous manufacturing process, make it suitable for various uses. Understanding these aspects can help businesses and individuals make informed decisions when selecting black annealed wire for their projects. Whether in construction, agriculture, or manufacturing, the importance of black annealed wire cannot be underestimated.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025