Nov . 18, 2024 10:42 Back to list

Specifications and Manufacturers of Black Annealed Wire for Industrial Applications

Understanding Black Annealed Wire Specifications and Factories

Black annealed wire is a specialized product widely used in various industries, including construction, manufacturing, and agriculture. Its unique properties, which arise from a combination of cold drawing and heat treatment processes, make it suitable for numerous applications. To better understand the black annealed wire specifications and the factories responsible for producing this material, we will explore its characteristics, manufacturing processes, and quality standards.

What is Black Annealed Wire?

Black annealed wire is a type of low-carbon steel wire that is processed to achieve a specific set of mechanical properties. The term black refers to the surface finish, which is darkened during the manufacturing process due to the removal of rust and oxidation. This wire is primarily characterized by its softness, ductility, and flexibility, making it ideal for various applications, including binding and tying.

Key Specifications

When discussing black annealed wire specifications, several factors come into play, including wire gauge, tensile strength, elongation, and coating. Common wire gauges range from 0.5mm to 4.0mm, accommodating diverse needs depending on the application. Black annealed wires typically exhibit tensile strengths of around 350 to 600 MPa, although this can vary based on the specific grade of steel used.

Elongation is another critical specification, reflecting the wire's ability to stretch before breaking. Annealed wire typically has high elongation percentages, often exceeding 15%, which is essential for applications requiring bending or reshaping. In terms of coating, while black annealed wire is usually not coated, it can sometimes be treated with a protective coating to enhance corrosion resistance, depending on the client's requirements.

Manufacturing Process

black annealed wire specification factories

The production of black annealed wire involves several stages. The process starts with the selection of high-quality low-carbon steel rods, which are then drawn into the desired wire gauge. Drawing the wire involves pulling it through a series of dies, progressively reducing its diameter. This phase is crucial as it determines the wire's mechanical properties.

After the drawing process, the wire undergoes annealing, where it is heated and then allowed to cool slowly. This heat treatment relieves internal stresses and enhances ductility, producing the desired softness. Finally, the wire is cooled and often spooled for distribution. Quality control is vital at every stage of production, ensuring that the final product meets industry standards.

Quality Standards in Factories

Manufacturers of black annealed wire are held to stringent quality standards. Various international standards, such as ISO 9001, often govern these factories to ensure consistency and safety in production. Factories typically conduct rigorous testing procedures to check for mechanical properties, such as tensile strength and elongation, as well as regular inspections for surface defects.

In addition, factories may be certified to various environmental and safety regulations, contributing to sustainable practices in wire manufacturing. Consistent quality output is not just beneficial for their reputation but also crucial for their clients' industries, where safety and reliability are paramount.

Conclusion

In conclusion, black annealed wire plays a vital role across many sectors due to its specific characteristics and versatility. Understanding its specifications and the manufacturing processes involved can help industries choose the right product for their needs. Furthermore, adherence to quality standards in factories ensures that this essential material remains reliable, safe, and efficient for a wide range of applications. As industries continue to evolve, the significance of high-quality black annealed wire will undoubtedly persist.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

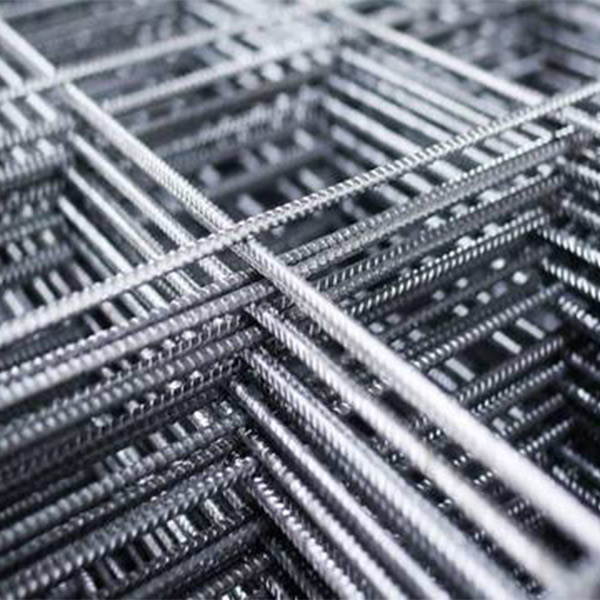

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025