Oct . 04, 2024 05:28 Back to list

black annealed wire specification factories

Understanding Black Annealed Wire Specifications in Manufacturing

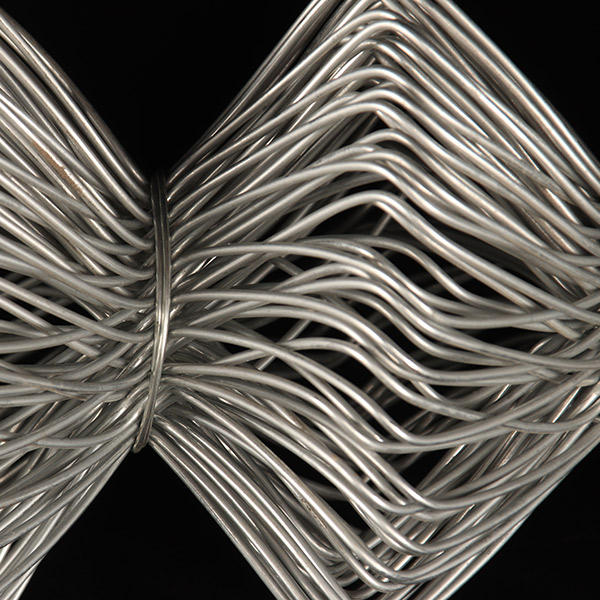

Black annealed wire is a widely used product in various industrial applications, primarily due to its excellent ductility and flexibility. It is produced through a specific drawing and annealing process, which enhances its mechanical properties and makes it suitable for different uses, including construction, agriculture, and manufacturing. The specifications of black annealed wire can vary from factory to factory, but there are standard characteristics that most manufacturers adhere to.

The primary material used for black annealed wire is low-carbon steel, which is known for its malleability and resistance to breaking under stress. The manufacturing process typically begins with drawing the wire through a series of dies to achieve the desired diameter. After this, the wire undergoes an annealing process, which involves heating the wire to a specific temperature and then allowing it to cool slowly. This heat treatment reduces internal stresses and improves the wire's ductility, making it easy to work with.

black annealed wire specification factories

When it comes to specifications, black annealed wire is often categorized by its diameter, tensile strength, and elongation percentage. The diameter can range from as small as 0.5 mm to larger sizes depending on the application. Generally, the standard tensile strength is in the range of 300 to 600 MPa, allowing it to withstand significant force without deformation. Elongation percentage is another vital parameter, indicating how much the wire can stretch before breaking; typically, higher elongation percentages suggest better quality and flexibility.

Factories that produce black annealed wire often comply with various international quality standards, such as ISO or ASTM, to ensure their products meet the necessary requirements for safety and performance

. Additionally, quality control measures are implemented throughout the manufacturing process to prevent defects and ensure consistency.In conclusion, black annealed wire plays an essential role in numerous industries due to its favorable properties and versatility. Understanding the specifications and the manufacturing process can help buyers select the right type of wire for their specific needs, ensuring optimal performance in their applications. As demand continues to grow, factories worldwide are focusing on improving their production methods to provide higher quality and more reliable black annealed wire to meet industry standards.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025