Nov . 11, 2024 02:18 Back to list

Top Quality Black Annealed Wire Production for Various Applications

Understanding Black Annealed Wire Insights from Manufacturers

In the manufacturing world, materials play a crucial role in determining the performance and longevity of various products. Among these materials, black annealed wire has gained popularity due to its unique properties and versatility. This article explores the significance of black annealed wire and looks into the insights gained from manufacturers in the industry.

What is Black Annealed Wire?

Black annealed wire is a type of wire that undergoes a specific annealing process. This process involves heating the wire to high temperatures and then allowing it to cool slowly. The result is a wire that exhibits improved ductility, malleability, and a softer texture, making it easier to work with during manufacturing processes. The “black” in its name refers to the surface finish of the wire, which is achieved through the oxidation that occurs during the annealing process.

Applications of Black Annealed Wire

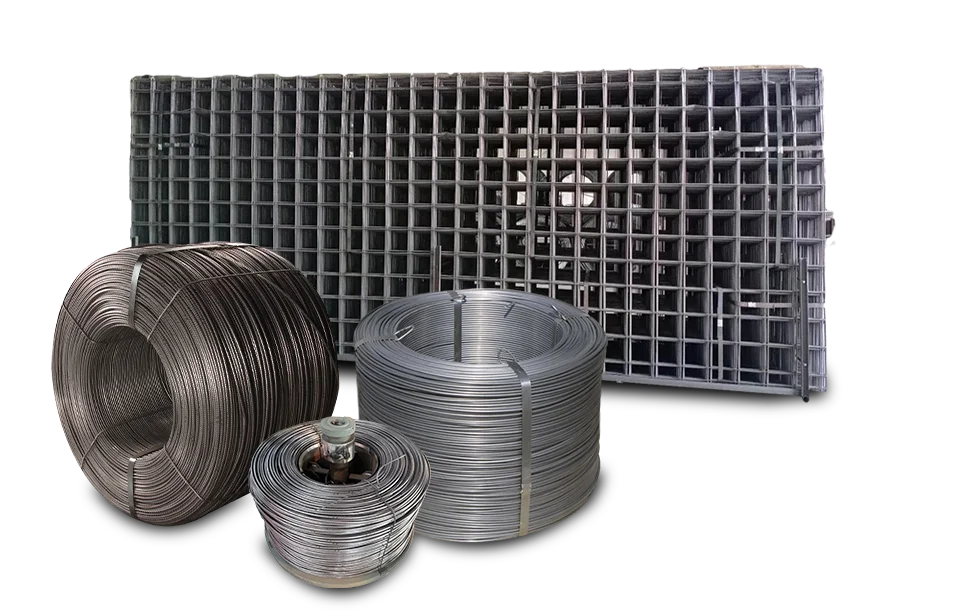

One of the primary uses of black annealed wire is in the agricultural sector, where it is commonly used for tying plants, supporting vineyard structures, and even fencing. Its flexibility and strength make it ideal for various applications that require durable yet soft materials. Manufacturers also produce black annealed wire for construction purposes, as it can be used for reinforcement in concrete, fabrication of wire mesh, and even in the production of various types of fasteners.

In addition to agriculture and construction, black annealed wire is utilized in the manufacturing of numerous household items, including hangers, jewelry, and decorative fixtures. Its aesthetic appeal, combined with its functional properties, has made it a favored choice among DIY enthusiasts and professional creators alike.

Insights from Manufacturers

black annealed wire manufacturer

Manufacturers of black annealed wire emphasize the importance of quality control throughout the production process. The raw materials used, typically low-carbon steel, significantly influence the wire's final properties. High-quality steel ensures that the wire attains the desired tensile strength and flexibility after annealing. Manufacturers often invest in advanced technology and skilled labor to monitor and maintain the quality at every production stage.

Moreover, environmental sustainability has become a key focus for many manufacturers in the black annealed wire industry. Initiatives to reduce waste and recycle materials are crucial as manufacturers are increasingly mindful of their environmental footprint. Many producers have adopted eco-friendly practices that not only enhance production efficiency but also align with global trends toward sustainability.

Market Trends and Demand

The demand for black annealed wire is expected to grow, driven by its various applications across multiple industries. As urbanization and agricultural practices expand, the need for reliable and durable materials like black annealed wire continues to rise. Manufacturers are adapting to this demand by innovating their production processes and exploring new markets.

Additionally, the rise of e-commerce has allowed manufacturers to reach a broader customer base. Online platforms now serve as vital channels for distribution, enabling manufacturers to connect directly with consumers and suppliers, ensuring a more streamlined supply chain.

Conclusion

In summary, black annealed wire represents a vital material in various industries, from agriculture to construction. Manufacturers play an essential role in delivering high-quality products that meet the needs of consumers. As the market evolves, the focus on quality, sustainability, and accessibility will shape the future of black annealed wire production. Understanding the nuances of this material and the insights from its manufacturers can lead to better utilization and innovation within the industry, supporting advancements that benefit a wide range of applications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025