Oct . 05, 2024 12:17 Back to list

Black Coated Annealed Iron Wire Manufacturing Plant Overview and Production Insights

The Black Annealed Iron Wire Factory A Cornerstone of Industrial Manufacturing

The black annealed iron wire factory stands as a pivotal establishment in the production of high-quality iron wire, widely used across various industries. This specialized facility transforms raw iron into a versatile product through a meticulous process that involves heating and cooling, ensuring optimal flexibility and strength.

Understanding Black Annealed Wire

Black annealed wire is a type of wire that undergoes an annealing process, where it is heated to a specific temperature and then cooled in a controlled environment. This treatment enhances the wire's ductility, making it easier to work with and less prone to breakage. The term black refers to the oxidized surface finish that results from the annealing process, which not only provides a unique aesthetic but also serves to protect the wire from corrosion.

The Production Process

The journey of raw materials into finished black annealed wire begins at the factory's dedicated production line. Initially, low-carbon steel wire is drawn through a series of dies, reducing its diameter while increasing its length. This process, known as wire drawing, is critical for achieving the desired thickness and strength of the wire.

Once drawn, the wire is subjected to the annealing process. This step is crucial as it alleviates internal stresses and improves flexibility. The factory utilizes advanced furnaces, carefully monitoring the temperature and atmosphere to achieve the perfect annealing conditions. After annealing, the wire is cooled gradually, allowing it to retain its characteristics effectively.

black annealed iron wire factory

Following the cooling phase, the black annealed wire undergoes surface treatment to enhance its finish. This may include oiling, which not only improves the wire's appearance but also provides additional protection against rust and environmental factors. Quality control tests are conducted throughout the manufacturing process to ensure that the final product meets the required industry standards.

Applications of Black Annealed Iron Wire

The versatility of black annealed iron wire makes it a popular choice in a variety of applications. It is widely used in the construction industry for reinforcing concrete, tying rebar, and supporting structures. Additionally, it serves as a reliable material for making fencing, cages, and other structural frameworks. Its flexibility and strength make it ideal for crafting various industrial products, including fasteners, clips, and chains.

In agriculture, black annealed wire is frequently employed for tying plants, constructing trellises, and building livestock enclosures. The ability to withstand harsh outdoor conditions while remaining malleable enough for easy handling has solidified its reputation as a staple in both commercial and residential settings.

Sustainability and Future Prospects

As industries increasingly pivot toward sustainable practices, black annealed iron wire factories are also adapting. Many are implementing eco-friendly measures, such as recycling scrap metal and utilizing energy-efficient technologies. By reducing waste and minimizing their carbon footprint, these factories not only contribute to environmental conservation but also enhance their competitiveness in the global market.

In conclusion, the black annealed iron wire factory plays a crucial role in modern manufacturing, delivering a product that is indispensable across numerous sectors. With continued innovations and a commitment to sustainability, the future of black annealed wire production looks promising, catering to the evolving needs of an ever-changing industrial landscape. As we move forward, these factories will undoubtedly remain foundational to the infrastructure and economy that relies on their high-quality products.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

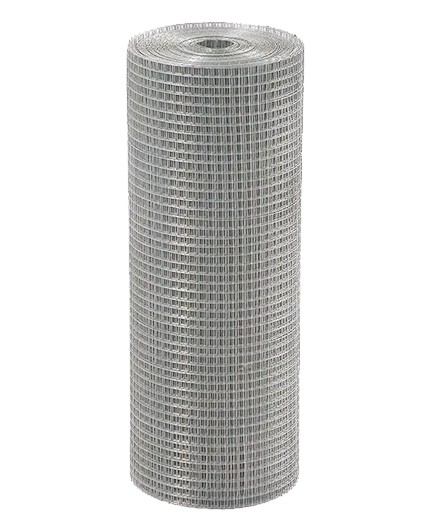

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025