Dec . 05, 2024 13:38 Back to list

Exploring the Characteristics and Applications of Black Annealed Iron Wire

The Versatile Applications of Black Annealed Iron Wire

Black annealed iron wire has established itself as a staple in various industries due to its unique properties and versatility. This type of wire, created through a specific annealing process that involves heating and cooling, yields a softer, more malleable product compared to regular iron wire. Its black color, resulting from the surface oxidation during the manufacturing process, not only adds aesthetic value but also enhances its corrosion resistance to a certain extent. This article delves into the characteristics, manufacturing process, and applications of black annealed iron wire.

Characteristics of Black Annealed Iron Wire

One of the most notable features of black annealed iron wire is its pliability. Unlike rigid iron wire, black annealed wire can be easily bent and twisted, making it suitable for a range of applications that require adaptability. It also exhibits good tensile strength, allowing it to endure considerable stress without breaking. Additionally, its surface provides excellent adhesion when coated, which is particularly advantageous for decorative applications.

The annealing process itself is crucial in defining the wire's dimensions and properties. During this process, the wire is heated to a specific temperature and then cooled, which relieves internal stresses and improves its ductility. The result is a wire that can be cut, shaped, or twisted into different forms without compromising its integrity. The blackened finish of this wire also means it has lower reflectivity, which can be particularly useful in reducing glare in various applications.

Manufacturing Process

The manufacturing of black annealed iron wire starts with high-quality low carbon steel wire rods. These rods are drawn down to the desired diameter using wire drawing machines. The drawn wire is then subjected to the annealing process, where it is heated in a controlled environment, typically in a furnace, at high temperatures for a specific time. Afterward, the wire is allowed to cool slowly, which can take several hours, depending on the desired properties.

Following the annealing process, the wire is often left with a black oxide finish. This finish enhances the wire's resistance to rust and corrosion, although it is not completely rust-proof. After cooling, the wire can be spooled for easy handling and transport or processed further into various products depending on customer requirements.

black annealed iron wire

Applications of Black Annealed Iron Wire

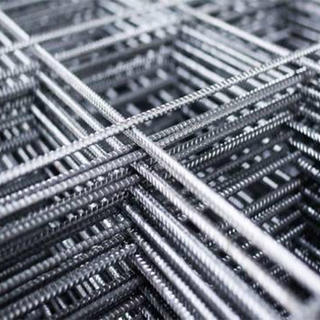

The applications of black annealed iron wire are vast and varied. One of its primary uses is in the construction industry, where it is commonly employed as a binding material for reinforcing bars (rebar) in concrete. The flexibility of black annealed wire makes it ideal for securely tying rebars together, contributing to the overall strength of structural components.

In agriculture, black annealed wire is widely used for fencing due to its strength and durability. Farmers often use it to create enclosures for livestock or to support crops. Its resistance to corrosion is especially beneficial in outdoor environments, helping to maintain the fencing's integrity over time.

Another application for black annealed iron wire is in the manufacturing of various household and decorative items. From wire frames for furniture to intricate designs in home decor, the wire's malleability allows artisans and manufacturers to create exquisite and durable products.

Additionally, black annealed iron wire is often utilized in the production of general industrial products, such as hangers, cables, and mesh. The wire's flexibility and tensile strength make it suitable for numerous heavy-duty applications, while its aesthetic qualities allow for use in more decorative pieces.

Conclusion

In conclusion, black annealed iron wire stands out for its unique properties and wide-ranging applications. Its strength, pliability, and visual appeal make it an ideal choice for numerous industries, from construction to agriculture and beyond. As industries continue to evolve, the demand for versatile materials like black annealed iron wire will undoubtedly grow, further establishing its importance in both industrial and decorative uses.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025