Aug . 20, 2024 12:53 Back to list

Black Annealed Soft Wire Production Facility Overview and Specifications

The Black Annealed Soft Wire Factory A Hub of Innovation and Quality

In the modern industrial landscape, the production of specialized materials plays a crucial role in various applications, from construction to manufacturing. One such significant product is black annealed soft wire, which has gained prominence due to its unique properties and versatility. A black annealed soft wire factory stands as a symbolic representation of innovation, quality control, and commitment to customer satisfaction in the wire manufacturing domain.

Black annealed wire is primarily made from high-quality steel, which undergoes a specialized annealing process. This process involves heating the wire in controlled conditions to enhance its properties, resulting in a softer and more ductile product. This wire is characterized by its smooth surface and black oxide coating, which not only serves aesthetic purposes but also provides resistance against rust and corrosion. These attributes make black annealed soft wire an ideal choice for numerous applications, including fencing, binding, and various forms of construction.

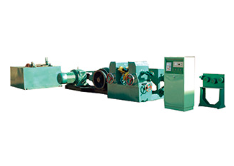

The manufacturing process in a black annealed soft wire factory is meticulous and requires state-of-the-art machinery. From the initial stages of wire drawing to the final annealing process, every step is carefully monitored to ensure precision and quality. Advanced technology is integrated into the systems to enhance efficiency and reduce waste, ultimately contributing to sustainability—a highly regarded principle in today’s manufacturing sectors.

Quality control is a cornerstone of operations in such a factory. Rigorous testing and inspection protocols are enforced at each stage of production to ensure that the end product meets the established industry standards. This involves tensile testing, surface examination, and continuous monitoring of the annealing process. By adhering to these quality benchmarks, the factory is able to supply products that not only meet customer expectations but also comply with regulatory guidelines, thereby establishing trust and credibility in the market.

black annealed soft wire factory

In addition to quality and technology, a black annealed soft wire factory is also distinguished by its commitment to customer service. Understanding the diverse needs of clients is crucial for success. The factory often works closely with clients to provide customized solutions, tailoring products to specific requirements. This flexibility enables businesses to optimize their operations and applications, leading to enhanced productivity and efficiency. Customer feedback is not only valued but also integral to the continuous improvement of the manufacturing processes.

The impact of a black annealed soft wire factory extends beyond its immediate products. As a significant player in the supply chain, it contributes to various sectors of the economy, fostering job creation and community development. By engaging with local suppliers and employing local talent, the factory helps to stimulate economic growth and enhance the livelihoods of individuals in the region.

Moreover, in an era where environmental concerns are paramount, many black annealed soft wire factories are taking steps to minimize their ecological footprint. Implementing green practices such as recycling scrap materials, reducing energy consumption, and ensuring safe waste disposal contributes to a more sustainable manufacturing process, aligning with global efforts to combat climate change.

In conclusion, a black annealed soft wire factory epitomizes the blend of tradition and innovation in modern manufacturing. Through a commitment to quality, customer satisfaction, and sustainability, these factories play an indispensable role in supplying high-quality wire products that serve a plethora of applications. As industries continue to evolve, the contributions of such factories will remain vital in meeting the demands of a dynamic market while fostering economic and environmental responsibility.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025