Dec . 09, 2024 17:23 Back to list

Manufacturer of Durable Binding Iron Wire for Various Applications

Exploring the World of Binding Iron Wire Manufacturers

Binding iron wire is a fundamental material used across various industries, from construction to agriculture. It provides strength, durability, and versatility, making it an essential component in a multitude of applications. As the demand for binding iron wire grows, manufacturers have risen to the challenge, optimizing production processes to meet international standards and customer expectations.

Understanding Binding Iron Wire

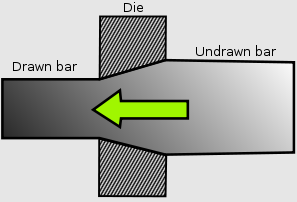

Binding iron wire is typically made from mild steel or iron, which is drawn into wire through a series of processes involving heating and reformation. The wire comes in different gauges, depending on its intended use, from lightweight bindings to heavy-duty applications. One of the most common uses of binding iron wire is in the construction industry, where it is employed to tie rebar for reinforcing concrete structures, ensuring stability and strength.

In the agricultural sector, binding iron wire is frequently used for fencing, trellising, and tying plants. Its flexibility allows for easy handling and installation, making it a popular choice among farmers and gardeners. This type of wire is also employed in the manufacture of wire containers and cages, often seen in various industrial and logistical settings.

The Role of Manufacturers

The production of binding iron wire involves several steps, and manufacturers play a crucial role in ensuring quality and efficiency. Leading binding iron wire manufacturers invest in state-of-the-art machinery and technologies to streamline their operations. This includes advanced wire drawing machines, automated packaging systems, and stringent quality control measures.

binding iron wire manufacturer

Quality assurance is vital for binding iron wire manufacturers. Manufacturers must adhere to various international standards, such as ISO certifications, to guarantee that their products meet specific safety and performance criteria. Regular testing for tensile strength, durability, and coating integrity (if applicable) ensures that the wire can withstand environmental factors and mechanical stress over time.

Moreover, manufacturers are increasingly focusing on sustainability. Many companies are adopting eco-friendly practices, such as recycling scrap metal and minimizing waste during production. This approach not only reduces environmental impact but also appeals to consumers who prioritize sustainability in their purchasing decisions.

Market Trends and Challenges

The binding iron wire market has been influenced by various global trends. With the rise of urbanization and infrastructure development, there is a growing demand for binding iron wire in construction projects. Additionally, the increasing focus on sustainable farming practices has led to higher usage in agriculture, as farmers seek reliable materials for their operations.

However, manufacturers face challenges, including fluctuating raw material prices and competition from low-cost producers. To remain competitive, manufacturers must innovate and differentiate their products. This could involve developing specialized wires with enhanced properties, such as corrosion resistance or higher tensile strength, catering to specific market needs.

Conclusion

Binding iron wire manufacturers play a pivotal role in various industries by providing essential materials that support construction, agriculture, and beyond. As the demand for quality and sustainable products rises, manufacturers must continually adapt and innovate. The future of binding iron wire production lies in the balance of efficiency, quality, and environmental responsibility. By doing so, they can meet the evolving needs of consumers while contributing to a more sustainable world. Through ongoing advancements in technology and production methods, the binding iron wire industry is poised for growth, reinforcing its status as a vital component across multiple sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025