Jul . 25, 2024 06:45 Back to list

Benefits of Using Welded Wire Mesh for Reinforcement in Concrete Slab Production Process

The Importance of Welded Wire Mesh in Concrete Slab Construction

In the realm of construction, particularly in concrete slab fabrication, the integration of welded wire mesh (WWM) has garnered significant attention due to its myriad benefits. Welded wire mesh is essentially a sheet made of steel wires that have been welded together at their intersections, forming a robust grid structure. This innovative solution plays a vital role in enhancing the structural integrity and durability of concrete slabs.

Strength and Stability

One of the primary reasons for using welded wire mesh in concrete slab factories is the strength it provides. Concrete is inherently strong in compression, but it is relatively weak in tension. This is where WWM emerges as a crucial reinforcement material. By incorporating welded wire mesh into the slab, the tensile strength is considerably improved, thereby reducing the likelihood of cracks and structural failures. The grid pattern of the mesh ensures load distribution across the slab, which is particularly beneficial for areas that undergo heavy traffic or support significant weight.

Enhanced Durability

Durability is another critical aspect of concrete slabs, especially in environments exposed to harsh weather conditions or chemicals. Welded wire mesh serves as a barrier against the formation of cracks that can lead to water infiltration, rust, and eventual deterioration of the concrete. It helps maintain the structural integrity of the slab over time, ensuring it withstands the test of time and external stresses. In addition, the use of WWM can mitigate the effects of shrinkage that commonly occurs in curing concrete.

Cost-Effectiveness

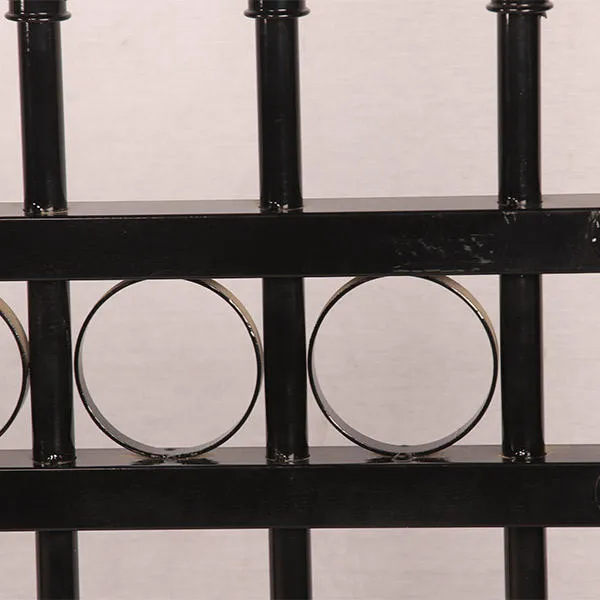

welded wire mesh in concrete slab factory

From a financial perspective, the incorporation of welded wire mesh into concrete slabs can be a cost-effective solution for construction projects. While the initial investment may seem significant, the long-term savings associated with reduced maintenance and repair costs often outweigh the upfront expenditure. A stable and durable slab minimizes the need for extensive repairs, which can be both labor-intensive and costly. Furthermore, the efficiency of WWM in improving construction timelines can lead to significant savings in labor costs.

Simplified Installation Process

The integration of welded wire mesh simplifies the installation process in concrete slab construction. Unlike traditional reinforcement methods, such as rebar, WWM can be easily handled and positioned. This not only expedites the construction process but also reduces labor requirements. With the mesh being pre-fabricated and available in custom sizes, it can be tailored to meet specific project requirements. This adaptability makes welded wire mesh an increasingly popular choice in modern construction practices.

Environmental Considerations

In today's environmentally conscious landscape, the use of welded wire mesh aligns with sustainable construction practices. Steel is a recyclable material, and employing it in construction minimizes the carbon footprint associated with building materials. Additionally, the longevity and durability imparted by WWM contribute to a longer lifespan for concrete structures, further minimizing resource consumption over time.

Conclusion

In conclusion, welded wire mesh plays a pivotal role in enhancing the performance and longevity of concrete slabs. Its benefits, including increased strength, improved durability, cost-effectiveness, simplified installation, and environmental advantages, make it an indispensable component in modern construction. As the construction industry continues to evolve, the use of welded wire mesh will likely become even more ingrained in standard practices, ensuring that concrete slabs remain resilient and reliable under various conditions. For any concrete slab factory, investing in high-quality welded wire mesh is not just a choice; it's a necessity for success in today’s competitive building environment.

-

High Quality Deformed Steel Bars China - Reliable Manufacturers & Suppliers for Construction Projects

NewsJul.08,2025

-

High Quality Black Annealed Wire - Durable Iron Wire 2mm from Leading Manufacturer & Supplier Factory

NewsJul.08,2025

-

Produce Hot Dipped Galvanized Steel Grating - High Quality Grating Supplier & Manufacturer

NewsJul.08,2025

-

Galvanized Iron Welded Wire Mesh Panels – Durable, Rust-Resistant, Best Price Manufacturer

NewsJul.07,2025

-

High Quality Concrete Reinforcing Welded Wire Mesh - Durable 8mm Steel Bar, Q188, A393, F72, High Strength Mesh Solutions

NewsJul.07,2025

-

High-Quality Redrawn G.I. Wire Leading Manufacturers & Suppliers

NewsJul.07,2025