Nov . 25, 2024 05:01 Back to list

arame recozido torcido manufacturer

The Rise of Arame Recozido Torcido A Manufacturer's Perspective

Arame recozido torcido, commonly known as twisted annealed wire, has gained significant traction in various industries due to its versatile applications and strong structural properties. As manufacturers continue to explore innovative ways to meet the growing demand for this essential material, understanding the intricacies of producing high-quality arame recozido torcido is crucial.

Understanding Arame Recozido Torcido

Arame recozido torcido is typically made from low-carbon steel wire. The annealing process ensures that the wire remains ductile and pliable, which is essential for its use in numerous applications such as construction, agriculture, and even in artistic endeavors. The twisted aspect refers to the method of producing the wire, where strands are twisted together to enhance strength and flexibility. This type of wire is well-regarded for its ability to withstand various stresses and environmental conditions, making it a preferred choice in multiple sectors.

Manufacturing Process

The manufacturing process of arame recozido torcido involves several essential steps

1. Wire Drawing The initial stage involves drawing raw steel through a series of dies to reduce its diameter. This step is critical, as it determines the wire's final strength and flexibility.

2. Annealing After drawing, the wire undergoes an annealing process. This thermal treatment is designed to relieve internal stresses, enhance ductility, and improve the overall workability of the wire. The annealing temperature and duration can significantly affect the wire's properties.

3. Twisting Once the wire is adequately annealed, manufacturers then twist multiple strands together to create the arame recozido torcido. This twisting process not only increases tensile strength but also adds to the wire’s aesthetic appeal, making it suitable for both functional and decorative uses.

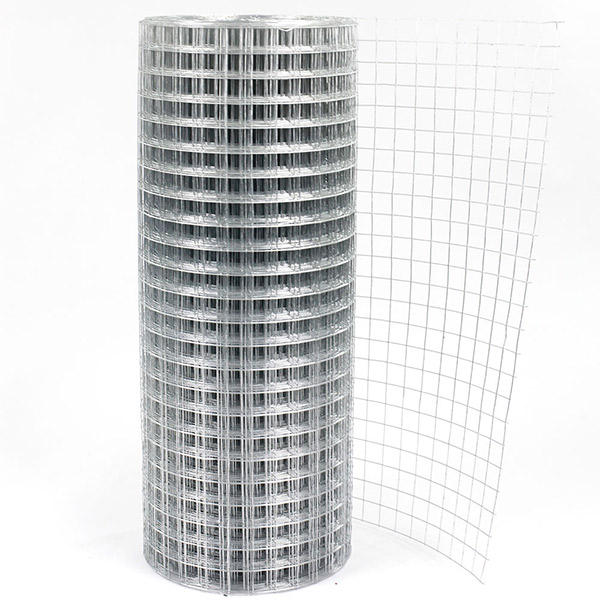

4. Coating (if required) Some manufacturers opt to apply a protective coating to the wire. This can help prevent rust and corrosion, particularly for applications in harsh environments. Options for coating include galvanizing and applying plastic or PVC coverings.

arame recozido torcido manufacturer

5. Quality Control Quality assurance is paramount in wire manufacturing. Rigorous testing for tensile strength, flexibility, and resistance to environmental factors are conducted to ensure the final product meets industry standards.

Applications

The versatility of arame recozido torcido makes it a favorite across various industries

- Construction It is commonly used in the reinforcement of concrete and masonry structures, where the strength and flexibility of twisted wire help to improve structural integrity.

- Agriculture Farmers utilize arame recozido torcido for fencing, trellising plants, and providing support for crops. Its durability in outdoor settings makes it an ideal choice for agricultural applications.

- Arts and Crafts Many artisans appreciate the pliability of twisted annealed wire, utilizing it for sculptures, jewelry making, and as a medium for various artistic projects.

- Manufacturing Various manufacturing processes require strong wire components, including those in the automotive and aerospace industries, where reliability and strength are critical.

The Future of Arame Recozido Torcido

As industries continue to evolve, the demand for innovative and reliable materials like arame recozido torcido is anticipated to increase. Manufacturers are increasingly focusing on incorporating sustainable practices into their operations. This includes utilizing recycled materials and adopting environmentally friendly processes, aligning with the global push for sustainability. Furthermore, technological advancements in manufacturing techniques are likely to improve efficiency and product quality.

In conclusion, arame recozido torcido represents a crucial component in a wide array of applications across different sectors. As manufacturers continue to innovate and adapt to market trends, the importance of this material will undoubtedly persist. Understanding the production processes, applications, and future trends offers a comprehensive view of the significance of arame recozido torcido in modern manufacturing. By embracing quality and sustainability, manufacturers can ensure that they meet the needs of consumers while contributing positively to the industries in which they operate.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025