Nov . 16, 2024 22:53 Back to list

arame recozido torcido factory

Exploring the World of Arame Recozido Torcido A Behind-the-Scenes Look at Its Manufacturing

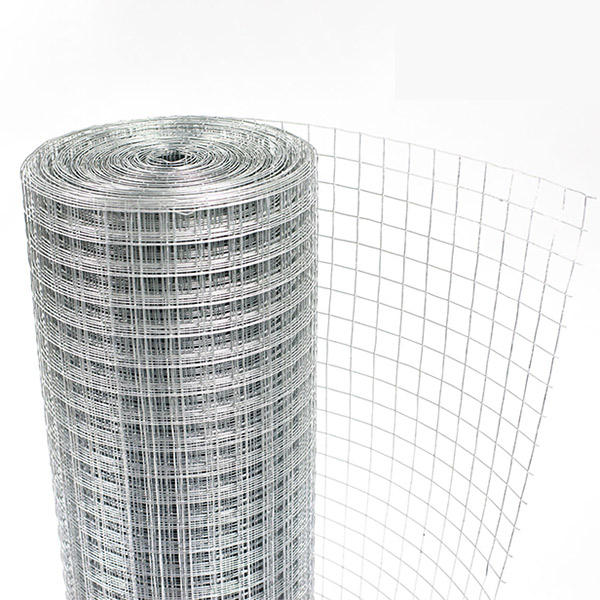

Arame recozido torcido, commonly known as twisted annealed wire, is an essential material utilized in various sectors, from construction to crafting. This versatile wire, characterized by its durability and flexibility, plays a critical role in reinforcing structures, bindings, and other applications. In this article, we will explore the manufacturing process of arame recozido torcido, diving into the factory's operations, technologies, and quality control measures that bring this essential product to life.

The Manufacturing Process

The journey of arame recozido torcido begins with raw materials, typically steel or iron wire. These materials are chosen for their strength and ductility, making them ideal for twisting and annealing processes. The factory starts by sourcing high-quality steel rods, which are then cut into manageable lengths for processing.

Once the rods are ready, they undergo a series of processes. Initially, the wire is drawn through a series of dies to reduce its thickness and enhance its tensile strength. This is a critical step, as the diameter of the wire must meet specific industry standards for its intended application. The drawing process requires precision machinery that ensures uniformity and consistency in the wire's dimensions.

After the wire has been drawn to the desired thickness, it undergoes the annealing process. Annealing involves heating the wire to a specific temperature and allowing it to cool slowly. This process effectively improves the wire’s malleability, making it easier to twist without breaking. The annealed wire is then coiled for ease of handling and further processing.

Twisting the Wire

arame recozido torcido factory

The most distinctive feature of arame recozido torcido is its twisted structure. The factory utilizes specialized machinery to twist multiple strands of the annealed wire together. This twisting process not only enhances the wire’s strength but also gives it its characteristic appearance. The twisting can vary in tightness and frequency depending on the requirements of the end product.

Quality control is crucial during the twisting phase. Operators conduct regular inspections to ensure that the twists are consistent and that the wire has not been compromised during the twisting process. A consistent twist contributes to the wire's structural integrity, making it suitable for various applications.

Finishing Touches and Quality Assurance

Once twisted, the wire undergoes additional treatments to enhance its properties further. This may include coating for rust resistance, additional annealing, or applying a protective finish to ensure longevity, especially in outdoor or harsh environments.

The final stages of production involve rigorous testing and quality assurance protocols. Factories employ a range of tests, from tensile strength assessments to flexibility evaluations, ensuring that the arame recozido torcido meets industry standards. After passing these tests, the wire is packaged for distribution, ready to be shipped to markets around the world.

Conclusion

The manufacturing of arame recozido torcido is a fascinating interplay of technology, craftsmanship, and quality control. From the selection of raw materials to the intricate processes of drawing, annealing, and twisting, every step is designed to create a product that meets the highest standards of durability and performance. This twisted annealed wire is more than just a material; it is a cornerstone for countless applications across various industries. Understanding its manufacturing process not only sheds light on its quality but also underscores its vital role in modern infrastructure and craftsmanship.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025