Dec . 11, 2024 11:26 Back to list

arame recozido torcido factories

Exploring the World of Twisted Recozido Yarn Factories and Innovations

In the ever-evolving textile industry, the production of specialized yarns plays a critical role in meeting the diverse demands of the market. Among these, twisted recozido yarn has emerged as a significant product, appreciated for its durability and unique texture. This article delves into the intricacies of twisted recozido yarn production, focusing on the factories that specialize in its manufacturing and the innovations driving this segment of the textile industry.

Understanding Twisted Recozido Yarn

Twisted recozido yarn is characterized by its intricate twisting technique, which enhances its strength and resilience. Traditionally, recozido refers to yarn that has been recycled or repurposed, making it an environmentally friendly option that appeals to modern consumers who are increasingly conscious of their carbon footprints. The twisting process involves taking individual fibers or strands and spiraling them together, which not only increases durability but also adds texture, making it ideal for a variety of applications, including fashion textiles, home furnishings, and industrial products.

Factory Operations The Heart of Production

The production of twisted recozido yarn takes place in specialized factories equipped with modern machinery and skilled labor. These factories are crucial in transforming raw materials—often sourced from sustainable practices—into high-quality yarn. The manufacturing process typically begins with the collection of recycled fibers, which are then cleaned and processed to remove impurities. This is followed by carding, where the fibers are aligned and prepared for spinning.

The spinning process is where the magic happens. Advanced spinning machinery twists the fibers together, creating a strong, cohesive yarn. Factories often employ different twisting techniques to achieve various textures and thicknesses, catering to the specific needs of different markets. For instance, some manufacturers focus on producing finer yarns for delicate fabrics, while others might specialize in heavier threads suitable for robust applications.

Innovation in Yarn Production

arame recozido torcido factories

The twisted recozido yarn market is not just about meeting current demands; it is also about innovation. Many factories are now investing in research and development to improve their processes and develop new products. Innovations in sustainable practices, such as waterless dyeing technologies and energy-efficient manufacturing processes, are becoming increasingly common. These practices not only reduce the environmental impact of yarn production but also enhance the overall quality of the final product.

Moreover, with the rise of digital technology, factories are incorporating automation and smart manufacturing tools to optimize their operations. This shift not only increases efficiency but also allows for greater customization of yarn products. With facilities now capable of producing small batches with specific attributes, manufacturers can respond swiftly to market trends and consumer preferences.

Challenges Faced by Factories

Despite the advancements and growth in the sector, factories producing twisted recozido yarn face several challenges. The need to balance sustainability with profitability often places them in a difficult position. Sourcing high-quality recycled fibers can be a challenge, as the availability of such materials fluctuates. Additionally, as regulations around environmental practices become more stringent, factories must adapt quickly to ensure compliance without compromising their production capabilities.

Furthermore, the competitive landscape of the textile industry means that factories must continually innovate and improve their offerings to maintain market share. The pressure to produce high-quality products at lower costs, while managing resource inputs effectively, requires strategic planning and execution.

Conclusion

The factories producing twisted recozido yarn are vital to the textile industry, serving as the backbone of a sustainable and innovative sector. Through a combination of traditional craftsmanship and modern technology, these facilities not only create high-quality yarns but also contribute to a more sustainable future. As consumer preferences continue to evolve, the role of these factories will be pivotal in driving the industry towards more eco-friendly practices and high-quality textile solutions. The journey of twisted recozido yarn from factory floor to finished product is a testament to the ingenuity and resilience of the textile industry in adapting to contemporary challenges while keeping sustainability at its core.

-

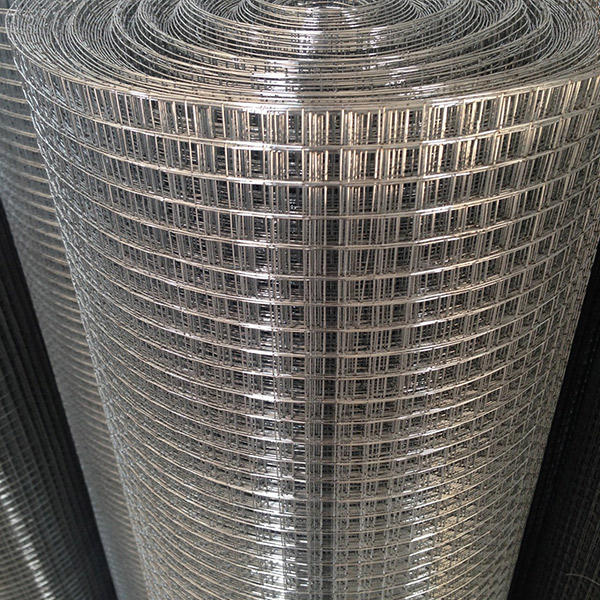

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025