Oct . 11, 2024 19:38 Back to list

annealed black wire iron black wire 2mm manufacturers

Understanding Annealed Black Wire A Deep Dive into 2mm Iron Black Wire Manufacturers

Annealed black wire, particularly in the 2mm diameter range, is an essential product in various industries due to its versatility and strength. This type of wire is typically made from low-carbon steel and undergoes an annealing process to enhance its ductility and malleability. Manufacturers of annealed black wire cater to a wide array of applications, including construction, automotive, agriculture, and arts and crafts.

What is Annealed Black Wire?

Annealed black wire is characterized by its dark color, attributed to a natural oxide layer formed during the manufacturing process. The annealing process involves heating the wire to a specific temperature and then cooling it slowly. This results in improved flexibility, making it easier to work with compared to non-annealed wire. The 2mm diameter is particularly popular for applications requiring strength without compromising on the ability to bend or twist the wire into different shapes.

Applications of 2mm Annealed Black Wire

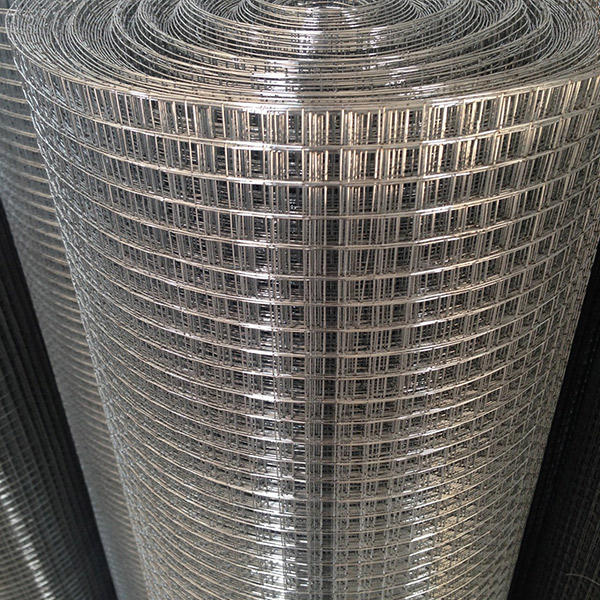

The 2mm annealed black wire serves multiple purposes across different industries. In construction, it is commonly used for reinforcing concrete, creating wire mesh, and securing structures. Its flexibility allows it to be easily shaped or tied, ensuring secure connections. In agriculture, this wire is employed for fencing, tying plants, and supporting crops. Its durability ensures that it withstands various weather conditions.

annealed black wire iron black wire 2mm manufacturers

In the realm of arts and crafts, 2mm annealed black wire is a favorite among artists and hobbyists. Its malleability makes it ideal for creating intricate designs, sculptures, or jewelry. The wire can be cut, bent, and manipulated without breaking, enabling unlimited creative possibilities.

Manufacturers of Annealed Black Wire

The market for annealed black wire producers has grown significantly due to increasing demand across sectors. Manufacturers often focus on quality control processes to ensure their products meet industry standards. The choice of a reliable manufacturer is crucial; several factors come into play, including the quality of raw materials, production techniques, and adherence to safety standards.

When selecting a manufacturer, clients should consider the specifications of the wire. The tensile strength, finished product diameter, and coating properties are essential aspects that influence wire performance. Top manufacturers often offer customizable solutions, tailoring wire specifications to fit unique customer needs.

Conclusion

In conclusion, annealed black wire, particularly in the 2mm size, plays a vital role in numerous applications across various industries. The flexibility, strength, and versatility of this wire make it a preferred choice among manufacturers and end-users alike. By understanding the significance of quality and choosing reputable suppliers, businesses can ensure they receive a product that meets their specific requirements, no matter the application.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025