Nov . 21, 2024 15:23 Back to list

annealed black wire factories

The Significance of Annealed Black Wire Factories in Modern Industry

In the modern manufacturing landscape, the role of specialized production facilities cannot be overstated. Among these, annealed black wire factories have emerged as crucial contributors to various industries, providing essential materials that serve a myriad of applications. Understanding the processes, advantages, and significance of these factories can shed light on their essential role in both industrial and commercial sectors.

What is Annealed Black Wire?

Annealed black wire is a type of wire that has undergone an annealing process—a heat treatment that enhances the wire's ductility and reduces its hardness. This treatment involves heating the wire to a specific temperature and then allowing it to cool slowly, improving its structural properties. The term black refers to the finish of the wire, which is typically a matte black color resulting from the presence of iron oxide on its surface. This wire is widely utilized in various applications, ranging from construction and agriculture to manufacturing and crafting.

The Annealing Process

The annealing process is vital for producing annealed black wire, as it significantly alters the physical characteristics of the wire. The heat treatment allows for better flexibility and easier handling, making it ideally suited for different applications that require bending, shaping, or twisting without breaking. Factories specializing in this type of production invest in advanced technology and equipment to ensure consistent quality and performance, allowing them to meet the diverse needs of their customers.

Applications and Benefits

Annealed black wire finds its way into an array of industries. In construction, it is commonly used for masonry ties, binding materials, and reinforcing concrete structures. In agriculture, it serves as an effective tool for fencing, trellising, and other support systems. Its malleable nature makes it a favorite among artists and DIY enthusiasts who use it in sculptures, crafts, and home improvement projects.

The benefits of using annealed black wire are manifold. Its enhanced flexibility allows for ease of installation, while the cost-effectiveness of production makes it an attractive option for budget-conscious projects. Additionally, the wire's durable nature ensures long-lasting performance, reducing the need for frequent replacements. Moreover, the matte finish is often preferred for aesthetic reasons, as it blends well with surrounding materials.

annealed black wire factories

The Role of Factories

The factories that produce annealed black wire are integral to supply chains across various sectors. They not only manufacture the wire but also play a critical role in ensuring that the products comply with industry standards and regulations. Quality control measures are implemented throughout the manufacturing process to guarantee that the final product meets the requirements set forth by customers and regulatory bodies.

Furthermore, these factories contribute to local economies by creating jobs and fostering innovation. The demand for high-quality annealed black wire drives the need for skilled labor, ensuring that local workers are trained in modern manufacturing techniques. Many factories also focus on sustainability, implementing eco-friendly practices to minimize their environmental impact.

Challenges and Future Prospects

Despite the advantages, annealed black wire factories face challenges, such as fluctuating raw material costs and increasing competition from international manufacturers. To remain competitive, these factories must continuously invest in technology, streamline operations, and prioritize customer service.

Looking ahead, the future for annealed black wire factories appears promising. As industries evolve, the demand for high-quality materials will continue to grow. Innovations in manufacturing processes, coupled with the expanding applications of annealed black wire, are likely to open new markets and opportunities.

Conclusion

In conclusion, annealed black wire factories play a pivotal role in various industries by providing essential materials that enhance production processes. Their significance extends beyond mere manufacturing; they contribute to local economies, support innovation, and ensure compliance with quality standards. As the industrial landscape continues to evolve, these factories are poised to adapt, thrive, and meet the ever-growing demands of modern manufacturing. Understanding their importance allows us to appreciate the intricacies of supply chains and the foundational materials that support our daily lives.

-

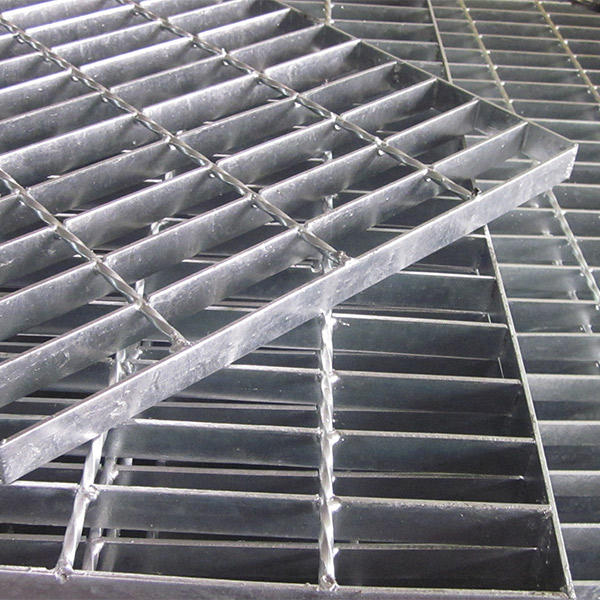

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025