Aug . 18, 2024 10:46 Back to list

Affordable Electro Galvanized Wire Suppliers with Competitive Pricing Options Available

The Growing Market for Electro-Galvanized Wire A Focus on Low-Price Manufacturers

In recent years, the demand for electro-galvanized wire has surged due to its versatile applications across various industries. Electro-galvanized wire is created through an electrochemical process that applies a coating of zinc to steel wire, enhancing its resistance to corrosion and rust. This type of wire is particularly favored in sectors like construction, automotive, agriculture, and manufacturing due to its strength, durability, and relatively low cost. With a thriving market landscape, the emergence of low-price manufacturers has become a significant focus, attracting businesses aiming to minimize operational costs without compromising on quality.

The Growing Market for Electro-Galvanized Wire A Focus on Low-Price Manufacturers

Low-price manufacturers have become pivotal in this competitive landscape. The key to their success lies in their ability to produce high-quality electro-galvanized wire at reduced prices. They often achieve this by optimizing their production processes, leveraging economies of scale, and sourcing raw materials at lower costs. As a result, they can offer competitive pricing to customers seeking budget-friendly options. This shift is particularly beneficial for small to medium-sized enterprises (SMEs) looking to manage budgets effectively while acquiring reliable materials for their projects.

electro galvanized wire low price manufacturers

Furthermore, these manufacturers often employ innovative technologies to enhance production efficiency. Automated machinery, for instance, can streamline the galvanization process, reduce wastage, and ensure consistent quality, all while keeping production costs down. This technological advancement enables manufacturers to meet the growing demands of the market while still offering their products at lower prices, making them attractive options for businesses across sectors.

However, purchasing from low-price manufacturers does come with certain considerations. While cost savings are appealing, buyers must ensure that they are not sacrificing quality. It is crucial to conduct thorough research and select manufacturers with a proven track record in delivering reliable electro-galvanized wire. Checking for certifications and product specifications can help ascertain that the wire meets the necessary standards for specific applications.

Moreover, building strong relationships with manufacturers can also benefit businesses. By working closely with suppliers, buyers can gain insights into upcoming price trends, changes in production capabilities, and new product innovations. This collaborative approach can lead to better procurement strategies and ultimately enhance the overall supply chain efficiency.

In conclusion, the market for electro-galvanized wire is flourishing, driven by its extensive applications and the competitive pricing offered by low-cost manufacturers. As industries continue to seek reliable and cost-effective solutions, these manufacturers play a crucial role in ensuring a steady supply of quality materials. By prioritizing quality alongside cost, businesses can leverage the advantages of electro-galvanized wire, contributing to their growth and success in a fiercely competitive marketplace. As the landscape evolves, it is vital for both suppliers and buyers to adapt to the changing dynamics, ensuring mutual benefit and sustained progress in the industry.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

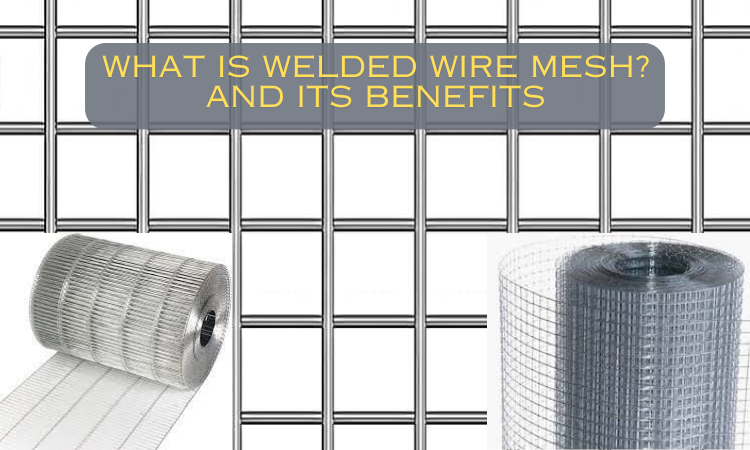

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025