Aug . 14, 2024 13:35 Back to list

Advantages of Using Welded Wire Mesh Panels in Concrete Construction Projects for Enhanced Durability

The Versatility of Welded Wire Mesh Panels in Concrete Applications

Welded wire mesh panels have become an essential component in the field of construction, particularly when integrated with concrete. These panels, which consist of a grid of steel wires welded together at their intersections, offer remarkable strength and versatility. Their applications range from reinforcing concrete floors to forming the backbone of precast concrete structures. In this article, we will explore the significance of welded wire mesh panels in concrete applications and their numerous benefits.

Strength and Durability

One of the primary reasons for the widespread use of welded wire mesh panels in concrete construction is their exceptional strength and durability. The welded intersections create a robust framework that can withstand significant loads, making them ideal for use in foundations, driveways, and pavements. When embedded within concrete, these panels help distribute stress evenly throughout the structure, reducing the risk of cracking and failure over time. This fortification is especially vital in areas that experience heavy traffic or extreme weather conditions.

Efficiency in Construction

Welded wire mesh panels also enhance the efficiency of the construction process. Their prefabricated nature allows for quick and easy installation, saving time on the job site. Rather than cutting and tying individual rebar pieces, construction workers can lay these panels directly into formwork, streamlining the reinforcement process. This efficiency not only accelerates project timelines but also reduces labor costs, making welded wire mesh a cost-effective solution for builders.

Versatile Applications

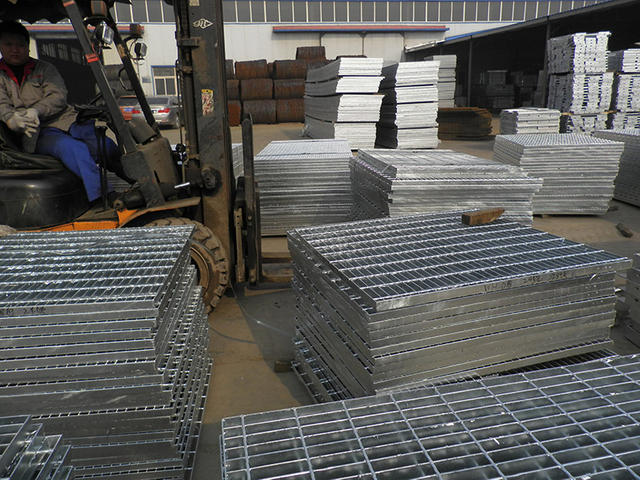

welded wire mesh panels concrete

The versatility of welded wire mesh panels extends beyond traditional concrete reinforcement. They are utilized in a variety of applications, including retaining walls, slabs, and even decorative features. In landscaping, welded wire mesh can support soil in garden beds or be used in gabion walls, which provide both structural benefits and aesthetic appeal. Additionally, in precast concrete manufacturing, these panels enable the production of standardized components that meet specific design requirements, allowing for greater flexibility in architectural innovation.

Enhanced Safety

Safety is paramount in any construction project, and welded wire mesh panels contribute significantly to site safety. The added reinforcement prevents sudden failures, lowering the risk of accidents and injuries during and after construction. Furthermore, the use of these panels helps meet building codes and standards, ensuring that structures are constructed to withstand natural forces such as earthquakes and winds.

Sustainability

As the construction industry increasingly prioritizes sustainability, welded wire mesh panels align with this trend. The lifespan of structures reinforced with welded wire mesh is typically longer due to reduced cracking and maintenance needs. This longevity leads to lower resource consumption over time, benefiting both the environment and the economy. Additionally, many welded wire mesh products are made from recycled materials, further minimizing their environmental impact.

Conclusion

In conclusion, welded wire mesh panels represent a significant advancement in concrete construction techniques. Their strength, efficiency, versatility, and role in enhancing safety make them a preferred choice among construction professionals. As technology progresses and the demand for durable, sustainable building solutions grows, the importance of welded wire mesh panels in concrete applications will continue to rise. By integrating these panels into their projects, builders can ensure that their structures not only meet but exceed the demands of modern construction standards.

-

Chain Link Fence-Galvanized Steel Fence Factory|Durable Security&Wire Mesh

NewsAug.15,2025

-

Chain Link Fence: Durable & Versatile Security Solution | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.15,2025

-

Chain Link Fence-Durable&Versatile|Anping County Puersen

NewsAug.15,2025

-

Welded Wire Mesh for Industry: Factory Supplier of Quality Mesh

NewsAug.15,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable, Versatile, Reliable Fencing Solution

NewsAug.14,2025

-

Chain Link Fence - Anping County Puersen|Durable&Versatile

NewsAug.14,2025