Nov . 11, 2024 12:41 Back to list

8mm cold drawn wire supplier

Exploring the World of 8mm Cold Drawn Wire A Supplier's Perspective

In the realm of metal fabrication and manufacturing, the importance of wire cannot be overstated. Among the various types of wire available, 8mm cold drawn wire has gained significant traction due to its strength, versatility, and precision. Cold drawing is a process that enhances the mechanical properties of the wire, making it suitable for various applications, from construction to automotive parts. This article delves into the characteristics, applications, and the role of suppliers in the realm of 8mm cold drawn wire.

What is Cold Drawn Wire?

Cold drawn wire is produced by pulling a wire through a die at room temperature, which helps to reduce its diameter while simultaneously increasing its tensile strength and hardness. The process involves several steps, including wire heating, drawing through a die, and subsequent conditioning. The end product boasts a smooth surface finish and uniform diameter, making it a favorite among manufacturers.

Characteristics of 8mm Cold Drawn Wire

1. Strength and Durability One of the standout features of 8mm cold drawn wire is its enhanced strength. The cold drawing process aligns the grain structure of the wire, resulting in improved tensile strength compared to hot rolled wire. This property is particularly advantageous in applications requiring high mechanical performance.

2. Dimensional Accuracy The precise nature of cold drawing results in a wire that maintains tight tolerances. When manufacturers require specific dimensions for their projects, 8mm cold drawn wire offers the reliability needed.

3. Versatile Applications The applications of 8mm cold drawn wire are vast. It is commonly used in the manufacturing of springs, fasteners, wire ropes, and various components in construction and automotive industries. Its versatility makes it an essential product in multiple sectors.

8mm cold drawn wire supplier

The Role of Suppliers

Suppliers of 8mm cold drawn wire play a critical role in ensuring quality, consistency, and availability of the product. Here are a few aspects of how suppliers contribute to the industry

1. Quality Assurance Leading suppliers implement stringent quality control measures to ensure that their 8mm cold drawn wire meets industry standards. This includes testing for tensile strength, ductility, and surface finish. Suppliers often provide certifications to reassure customers of the wire's quality.

2. Customization Different projects demand different specifications. Reputable suppliers often offer customized solutions, such as specific lengths, coatings, and finishes tailored to the needs of their clients. This flexibility ensures that manufacturers can obtain exactly what they require for their products.

3. Logistics and Delivery A reliable supplier understands the importance of timely delivery. With just-in-time manufacturing becoming a popular approach, suppliers must ensure that the 8mm cold drawn wire is delivered when needed. Efficient logistics systems help maintain a steady supply, reducing downtime for manufacturers.

4. Technical Support Knowledgeable suppliers often provide technical support to clients, assisting them in selecting the right materials for their applications. This guidance can help improve the overall efficiency of manufacturing processes.

Conclusion

The demand for 8mm cold drawn wire continues to rise as industries require materials that offer strength, precision, and versatility. The process of cold drawing not only enhances the wire's characteristics but also makes it a fundamental component in various manufacturing sectors. As suppliers of this essential material, the commitment to quality, customization, and customer support is vital for maintaining a competitive edge in the marketplace. For manufacturers looking for dependable wire solutions, collaborating with a reputable supplier of 8mm cold drawn wire is a crucial step toward achieving their production goals.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

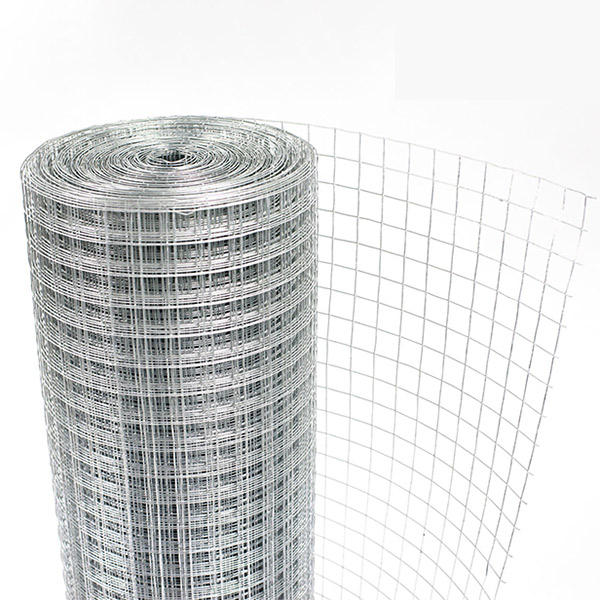

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025