Oct . 21, 2024 10:37 Back to list

High Quality 8mm Cold Drawn Wire Production by Leading Manufacturer

Understanding 8mm Cold Drawn Wire Manufacturing Process and Applications

Cold drawn wire has become a crucial component in various industrial applications due to its superior mechanical properties and versatile nature. Among the different sizes available, 8mm cold drawn wire stands out for its distinct applications in construction, automotive, and manufacturing. In this article, we will delve into the manufacturing process of 8mm cold drawn wire, its benefits, and typical applications.

What is Cold Drawn Wire?

Cold drawn wire is manufactured by drawing hot-rolled wire through a die at room temperature. This process results in a significant reduction in diameter while increasing the wire's strength and hardness. The cold drawing process also enhances the surface finish of the wire, making it smoother and more uniform.

The Manufacturing Process

1. Material Selection The first step in manufacturing cold drawn wire is selecting the right raw material. Steel is the most common choice, specifically low-carbon or high-carbon steel, depending on the desired properties of the final product.

2. Annealing Before the drawing process, the steel wire is often subjected to an annealing process. Annealing involves heating the wire to a specific temperature and then cooling it slowly. This process relieves internal stresses and improves ductility, making the wire easier to draw.

3. Cleaning The wire must be cleaned to remove any oxides or contaminants that may have been deposited during the annealing process. This is typically done using chemical solutions or mechanical means.

4. Drawing The cleaned wire is then drawn through a series of progressively smaller dies. During this process, the diameter of the wire is reduced while its length increases. For an 8mm diameter wire, this may involve multiple steps, with each die reducing the wire diameter incrementally.

5. Tempering and Final Treatments After the drawing process, the wire may undergo additional treatments such as tempering. Tempering involves reheating the wire to improve toughness without compromising hardness. This step is crucial for applications requiring specific mechanical properties.

6. Testing and Quality Control Finally, quality control measures are implemented to ensure that the wire meets specific standards in terms of diameter, tensile strength, and surface quality. Various tests, including tensile testing, dimensional checks, and visual inspections, are carried out before the wire is packaged and shipped.

8mm cold drawn wire manufacturer

Benefits of 8mm Cold Drawn Wire

Cold drawn wire offers several advantages over other types of wire. The cold drawing process increases tensile strength, which means that 8mm cold drawn wire can bear greater loads compared to its hot-rolled counterparts. The improved surface finish enhances its ability to be coated or welded, making it suitable for various applications.

Moreover, the consistent dimensional accuracy of cold drawn wire makes it more reliable for precision engineering tasks. Another advantage is its enhanced ductility, allowing for easier manipulation during manufacturing processes.

Applications of 8mm Cold Drawn Wire

The versatility of 8mm cold drawn wire makes it suitable for a multitude of applications

1. Construction It is commonly used in the construction industry for reinforcing concrete structures. The increased strength of cold drawn wire ensures that it can effectively support heavy loads.

2. Automotive In the automotive sector, 8mm cold drawn wire is used for various components including springs, which require high tensile strength and fatigue resistance.

3. Manufacturing It can also be utilized in the manufacturing of cables, fasteners, and other critical components that demand high precision and reliability.

4. Furniture Manufacturers often use cold drawn wire in the production of furniture frames and other decorative elements due to its durability and aesthetic appeal.

Conclusion

As industries continue to evolve, the demand for high-quality materials such as 8mm cold drawn wire will undoubtedly rise. Understanding its manufacturing process highlights the intricate steps involved in producing a product that meets stringent quality and performance standards. With its diverse range of applications and superior mechanical properties, 8mm cold drawn wire remains a vital material in modern engineering and manufacturing sectors.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

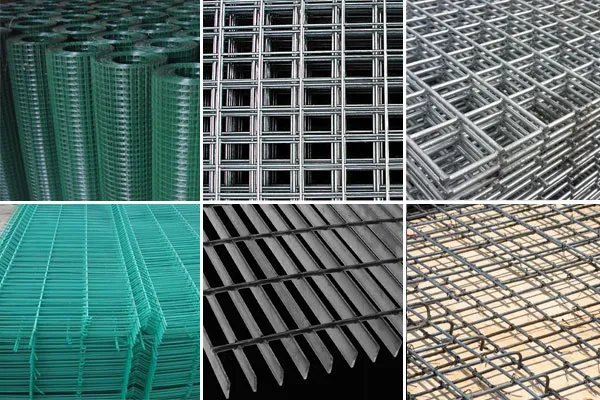

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025