Nov . 29, 2024 22:32 Back to list

Quality 8 Gauge Galvanized Wire Manufacturing for Reliable Construction and Outdoor Projects

Understanding the 8% Gauge Galvanized Wire Factory

In the vast world of manufacturing and construction, galvanized wire plays a crucial role in various applications due to its durability and resistance to corrosion. Among the different gauges of wire available today, the 8% gauge galvanized wire stands out for its strength and versatility. This article will explore the operations of a typical factory that specializes in producing 8% gauge galvanized wire, along with its applications and advantages.

Understanding the 8% Gauge Galvanized Wire Factory

After the wire is drawn, the next step involves galvanization. This is a crucial process that involves coating the wire with a layer of zinc. The galvanization not only enhances the wire's resistance to rust and corrosion but also extends its lifespan, making it ideal for use in various environmental conditions. The most common methods of galvanization include hot-dip galvanizing and electro-galvanizing, each offering unique benefits depending on the intended application.

8 gauge galvanized wire factory

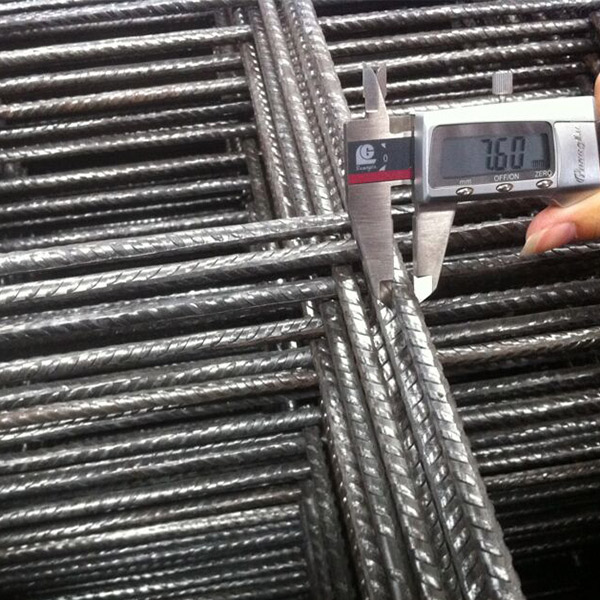

Quality control is an integral part of the manufacturing process in a galvanized wire factory. From raw materials to the final product, rigorous testing and inspections are conducted to ensure that the wire meets industry standards. Parameters such as tensile strength, flexibility, and adhesion of the zinc coating are meticulously evaluated. This commitment to quality assurance is what builds trust and reliability for customers who depend on galvanized wire for critical applications.

The applications of 8% gauge galvanized wire are extensive. It is widely used in construction for reinforcing concrete structures, creating fences, and making wire mesh. Additionally, industries such as agriculture and electronics also rely on this type of wire for various purposes, including the production of durable fencing and electrical components. Its strength and resistance to corrosion make it a preferred choice in outdoor settings, where it can withstand harsh weather conditions.

In conclusion, a factory specializing in 8% gauge galvanized wire plays a significant role in the supply chain for numerous industries. By combining robust manufacturing processes with strict quality control, these factories ensure that the end product is not only reliable but also versatile enough to meet diverse needs. As demand for durable construction materials continues to grow, the significance of galvanized wire factories will likely increase, solidifying their place in modern manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025