Oct . 19, 2024 10:18 Back to list

8 gauge galvanized wire factory

Understanding the Production of 8% Gauge Galvanized Wire A Comprehensive Overview

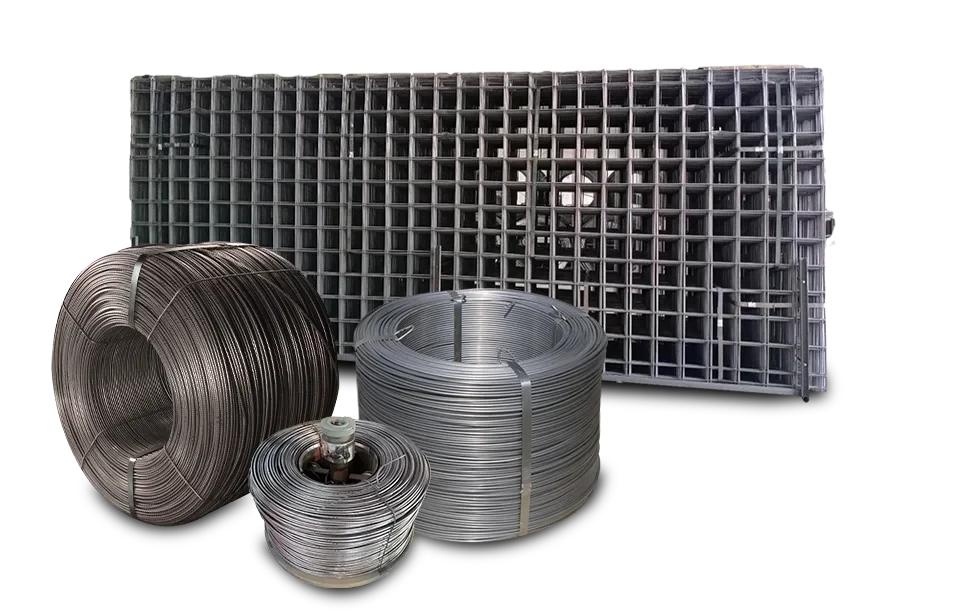

Galvanized wire is widely used in various industries due to its durability, corrosion resistance, and versatility. Among the different gauges available, the 8% gauge galvanized wire stands out for specific applications ranging from construction to agriculture. This article delves into the characteristics, manufacturing processes, applications, and advantages of 8% gauge galvanized wire, while also shedding light on the importance of factories specializing in its production.

What is 8% Gauge Galvanized Wire?

The term gauge refers to the diameter of the wire, and an 8% gauge typically indicates a wire thickness of approximately 4.0 mm. The galvanized finish implies that the wire has undergone a protective treatment involving the application of a zinc coat. This coating helps prevent rust and corrosion, ensuring that the wire maintains its integrity even in harsh environments.

The Manufacturing Process

The production of 8% gauge galvanized wire begins with the selection of high-quality steel wire rod as the primary material. The manufacturing process can be broken down into several key stages

1. Wire Drawing The wire rod is drawn through a series of dies to reduce its diameter to the desired gauge. This process enhances the wire’s tensile strength and prepares it for galvanization.

2. Cleaning Before galvanization, the wire must be cleaned to remove any impurities, oil, or oxides that may hinder the adhesion of the zinc coating. This is typically achieved through a combination of mechanical and chemical processes.

3. Galvanization The cleaned wire is then subjected to galvanization, commonly done through the hot-dip method. In this process, the wire is immersed in molten zinc, providing a robust coating that can withstand environmental stressors. The thickness of the zinc layer can be controlled, ensuring optimum performance for specific applications.

4. Cooling and Inspection After the galvanization process, the wire is cooled and inspected for any defects, including consistency in diameter, strength, and zinc coating thickness. Quality control is crucial to ensure that the final product meets industry standards.

8 gauge galvanized wire factory

Applications of 8% Gauge Galvanized Wire

The versatility of 8% gauge galvanized wire makes it suitable for various applications

- Fencing Due to its strength and durability, this wire is often used in agricultural and industrial fencing. It provides a reliable barrier while remaining resistant to rust and corrosion. - Construction In the construction industry, the wire is utilized in various structural applications, including reinforcement in concrete, tie-downs, and as part of composite materials. - Crafts and DIY Projects Hobbyists often use galvanized wire for craft projects, as its flexibility allows for creative designs while providing the necessary strength.

- Industrial Uses In manufacturing settings, the wire is employed in the creation of products such as wire mesh, crates, and baskets, where structural integrity and resistance to environmental factors are crucial.

Advantages of 8% Gauge Galvanized Wire

One of the primary benefits of 8% gauge galvanized wire is its durability. The zinc coating significantly extends the wire’s lifespan, reducing the need for frequent replacements. Moreover, being resistant to various weather conditions, it can be used effectively in both indoor and outdoor applications.

Additionally, the wire’s tensile strength makes it ideal for high-load applications and ensures that it can withstand physical stress without breaking. Its versatility also allows manufacturers and consumers to utilize it across various industries, adding to its appeal.

Conclusion

The production of 8% gauge galvanized wire is a detailed process that combines advanced manufacturing techniques with high-quality materials. As industries demand stronger, more durable, and corrosion-resistant materials, the importance of factories specializing in this product continues to grow. Understanding its characteristics and applications not only showcases its value but also highlights the critical role it plays in modern construction, agriculture, and beyond. With ongoing innovations and advancements in manufacturing, 8% gauge galvanized wire is poised to remain a cornerstone material for years to come.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025