Nov . 23, 2024 13:25 Back to list

8 gauge galvanized wire factories

The Role of 8 Gauge Galvanized Wire Factories in Modern Manufacturing

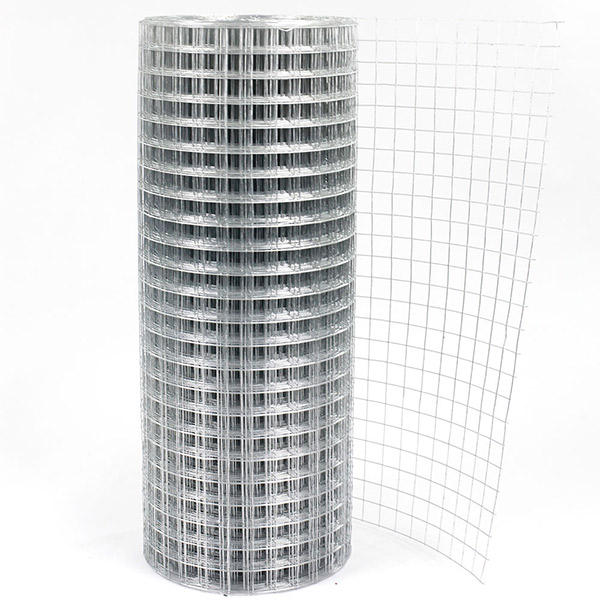

In today's industrial landscape, the demand for durable and versatile materials is at an all-time high. One such material that has gained significant traction is the 8 gauge galvanized wire. With its excellent strength-to-weight ratio, corrosion resistance, and adaptability, this type of wire is essential in various applications, ranging from agriculture to construction and beyond. The factories producing 8 gauge galvanized wire play a pivotal role in meeting this demand, driving innovation, and ensuring quality.

Understanding 8 Gauge Galvanized Wire

First and foremost, it's essential to understand what the term 8 gauge means in the context of wire. The gauge system is a method of measuring wire thickness; the lower the gauge number, the thicker the wire. An 8 gauge wire, which measures approximately 0.1285 inches in diameter, is substantial enough to support heavy loads while remaining manageable for various applications. The galvanization process, which involves coating the wire with zinc, enhances its resistance to rust and corrosion, making it particularly suited for outdoor use.

The Importance of Manufacturing Standards

8 gauge galvanized wire factories are characterized by their adherence to stringent manufacturing standards. These standards ensure that the wire produced is not only robust but also meets the specific needs of different industries. Factories often implement quality control measures at every stage of production, from raw material selection to the final inspection. This quality assurance is crucial, as the wire is often used in critical applications such as fencing, electrical wiring, and support structures.

Technological Advancements in Production

8 gauge galvanized wire factories

Modern 8 gauge galvanized wire factories leverage cutting-edge technology to enhance their production processes. Automated machinery improves efficiency and precision, allowing for consistent quality across large batches. Innovations such as computer-controlled galvanizing lines help ensure that the coating thickness is uniform, which significantly contributes to the wire's longevity and effectiveness in preventing corrosion. Additionally, factories are increasingly adopting environmentally friendly practices, such as recycling water used in the galvanization process and reducing waste.

Sustainability Initiatives in Wire Production

The shift towards sustainable manufacturing is a critical trend in today's industrial sector. Many 8 gauge galvanized wire factories are incorporating eco-friendly practices to minimize their environmental impact. This includes sourcing raw materials from sustainable suppliers and implementing energy-efficient processes. By focusing on sustainability, these factories not only comply with regulatory requirements but also appeal to a growing base of environmentally conscious consumers and businesses.

Meeting Diverse Industry Needs

The versatility of 8 gauge galvanized wire makes it an invaluable resource across various sectors. In the agricultural industry, it is often used for constructing livestock enclosures and trellises. In construction, its strength is relied upon for reinforcing concrete and creating tensioned support systems. Additionally, industries such as telecommunications and electrical contracting utilize galvanized wire for securing cables and other essential infrastructure.

Conclusion

In conclusion, the significance of 8 gauge galvanized wire factories in modern manufacturing cannot be overstated. These factories ensure that high-quality, durable, and versatile wire is available to meet the demands of various industries. As they continue to embrace technological advancements and sustainability initiatives, they will pave the way for a more efficient and eco-friendly future. The essential role of these factories not only supports economic growth but also contributes to the advancement of infrastructure and industry standards worldwide. As we look ahead, the ongoing evolution of 8 gauge galvanized wire production will undoubtedly play a key role in shaping the materials we rely on in our daily lives.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025