Nov . 18, 2024 12:31 Back to list

6mm welded panel manufacturer

Understanding 6mm Welded Panels A Comprehensive Guide to Manufacturers

In recent years, the construction and manufacturing sectors have witnessed a surge in demand for durable and reliable materials. Among these materials, welded panels, particularly those with a thickness of 6mm, have gained significant attention due to their strength, versatility, and ease of use. This article will explore the essential aspects of 6mm welded panels, their applications, and what to consider when choosing a manufacturer.

What are 6mm Welded Panels?

Welded panels are sheets or structural elements made from metal that have been joined together with a welding technique. A thickness of 6mm is commonly favored in various applications because it strikes a balance between strength and weight, making it suitable for both structural and decorative purposes. The panels can be made from various materials, including steel, aluminum, and stainless steel, and can feature different finishes to enhance their aesthetic appeal and resistance to corrosion.

Applications of 6mm Welded Panels

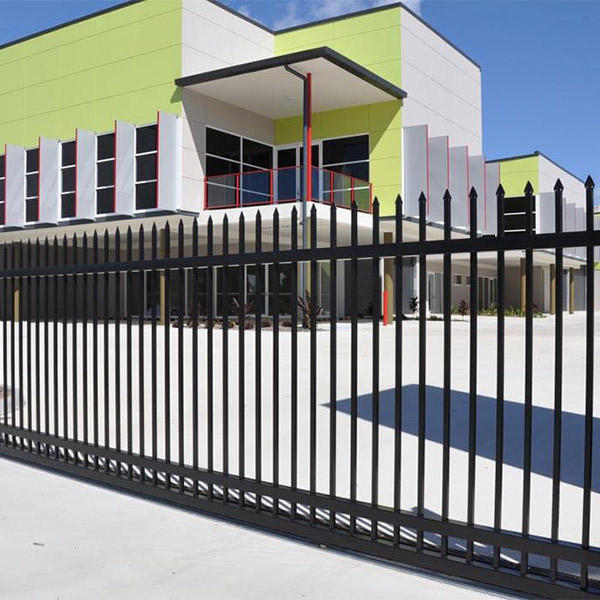

The applications of 6mm welded panels are diverse. In the construction industry, they are frequently used for walls, ceilings, and partitions in buildings, providing both structural support and a sleek finish. Their robust nature makes them ideal for industrial settings, such as factories and warehouses, where safety and longevity are paramount. Additionally, these panels can be utilized in the manufacturing of furniture, display fixtures, and outdoor structures like fences and gates.

Another significant application of 6mm welded panels is in the agricultural sector. They are commonly used in the construction of livestock enclosures, storage facilities, and equipment shelters, ensuring that these structures can withstand harsh conditions while providing safety and security for animals and equipment alike.

Choosing the Right Manufacturer

When it comes to sourcing 6mm welded panels, selecting the right manufacturer is crucial. Here are several factors to consider

6mm welded panel manufacturer

1. Quality Standards Ensure that the manufacturer adheres to international quality standards. Look for certifications such as ISO, which indicates a commitment to quality control and ensuring the durability of their products.

2. Material Specifications Different applications may require specific types of materials. Confirm that the manufacturer can provide panels made from materials suitable for your specific needs, such as corrosion-resistant options for outdoor applications.

3. Customization Options Depending on your project requirements, you may need custom-sized panels or specific finishes. A reputable manufacturer should offer versatile customization options to cater to unique designs and preferences.

4. Production Capacity Assess the manufacturer’s production capacity and lead times. This is particularly important for large-scale projects where timelines are critical. Ensure that the manufacturer can meet your deadlines without compromising on quality.

5. Experience and Reputation A manufacturer with a proven track record will likely understand the intricacies of producing high-quality welded panels. Look for companies with positive customer reviews and testimonials as this can provide insight into their reliability and customer service.

6. After-Sales Support After purchasing welded panels, having access to support is essential. Whether you have questions about installation or need warranty services, a manufacturer who offers good after-sales support can make a significant difference to your overall experience.

Conclusion

In conclusion, 6mm welded panels present an excellent solution for a variety of applications, thanks to their strength and adaptability. Selecting the right manufacturer is vital to ensure that you receive high-quality panels that meet your specific needs. By considering factors such as quality standards, material specifications, customization options, and manufacturer reputation, you can make an informed decision that will contribute to the success of your projects. Ultimately, investing time in researching and choosing a reputable manufacturer will lead to high-quality results that stand the test of time.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025