Nov . 05, 2024 17:12 Back to list

6mm-12mm wire gauge cold drawn wire factory

The Importance of 6mm to 12mm Wire Gauge Cold Drawn Wire in Manufacturing

In the manufacturing industry, the specifications of raw materials play a crucial role in determining the quality and performance of the end products. Among these materials, wire is particularly significant, with various gauges serving different applications. One of the most commonly sought-after sizes is the 6mm to 12mm wire gauge, especially the cold drawn variety. This article will delve into the properties, advantages, and applications of 6mm to 12mm wire gauge cold drawn wire, shedding light on why manufacturers prefer this type of wire.

What is Cold Drawn Wire?

Cold drawn wire is produced through a process of drawing wire at room temperature, which results in enhanced tensile strength and better surface finish compared to hot-rolled wire. The cold drawing process involves pulling the wire through a series of dies, reducing its diameter while increasing its length. This not only refines the dimensions of the wire but also improves its mechanical properties.

The cold drawing technique can be applied to various materials, including steel, stainless steel, and other alloys. However, for the context of this article, we will focus primarily on cold drawn steel wire in the 6mm to 12mm gauge range.

Advantages of 6mm to 12mm Cold Drawn Wire

1. Superior Strength Cold drawn wire exhibits significantly higher tensile strength than its hot-rolled counterparts. This property is essential for applications that require durability and resistance to deformation under stress.

2. Excellent Surface Finish The cold drawing process not only improves strength but also results in a smoother surface finish. This is crucial for applications where contact with other materials may cause wear or corrosion.

3. Dimensional Accuracy The cold drawing method provides remarkable control over the dimensions of the wire, ensuring consistency and precision. This precision is vital for engineering applications where tolerances are critical.

4. Enhanced Ductility Despite the increased strength, cold drawn wire maintains a certain level of ductility, allowing it to be formed and shaped without breaking. This trait is particularly useful in various manufacturing processes.

6mm-12mm wire gauge cold drawn wire factory

5. Corrosion Resistance When made from certain alloys, cold drawn wire can exhibit excellent resistance to corrosion, making it suitable for outdoor and marine applications.

Applications of 6mm to 12mm Cold Drawn Wire

The versatility of 6mm to 12mm cold drawn wire makes it suitable for a wide range of applications across various industries

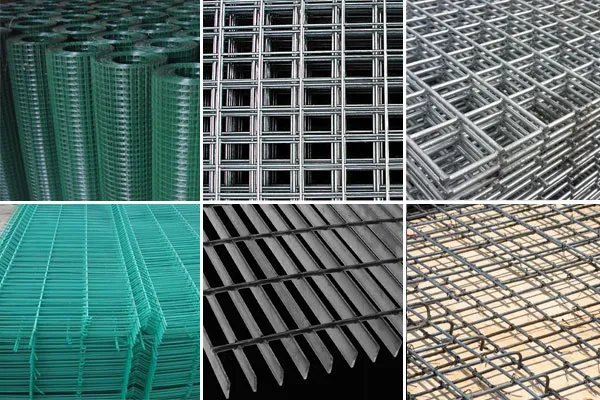

1. Construction Industry This type of wire is often used in the construction sector for reinforcing concrete, manufacturing wire ropes, and creating mesh structures that require high tensile strength and durability.

2. Automotive Industry The automotive industry uses cold drawn wire for essential components such as springs, cables, and structural elements that must withstand significant stress and strain during operation.

3. Electronics In the electronics sector, manufacturers utilize cold drawn wire for windings, connectors, and other components that require fine, accurate measurements and high conductivity.

4. Furniture Manufacturing Designers in the furniture industry appreciate the strength and aesthetic qualities of cold drawn wire, using it in various pieces such as frames, supports, and decorative elements.

5. Fasteners The production of high-quality screws, bolts, and other fasteners often employs cold drawn wire due to its strength and reliable performance.

Conclusion

The 6mm to 12mm wire gauge cold drawn wire represents a quintessential element in modern manufacturing processes. Its unique blend of strength, precision, and versatility makes it an irreplaceable material for various industries. As technology continues to advance, the demand for high-quality cold drawn wire will only increase, paving the way for innovations in manufacturing applications. Understanding the benefits and applications of this material helps manufacturers make informed decisions, ensuring their products meet the highest standards of quality and performance. In an era where efficiency and reliability are paramount, cold drawn wire stands out as a cornerstone of industrial manufacturing.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025