Nov . 11, 2024 18:23 Back to list

6mm-12mm wire gauge cold drawn wire factory

The Importance of Cold Drawn Wire in Manufacturing A Look at 6mm-12mm Gauge

In the realm of modern manufacturing, the choice of materials can significantly influence the performance, durability, and overall quality of finished products. One such material that has gained prominence in various industrial applications is cold drawn wire, particularly in the gauge range of 6mm to 12mm. This article delves into the intricacies of cold drawn wire factories, the benefits of cold drawing processes, and the critical applications of this product.

Understanding Cold Drawn Wire

Cold drawn wire is produced by pulling metal wires through a series of dies at room temperature. This process, known as cold drawing, enhances the mechanical properties of the metal, making it stronger and more durable. Unlike hot drawn wire, which is shaped at elevated temperatures, cold drawn wire maintains its original properties while achieving finer tolerances and a smoother surface finish. The typical diameter range for cold drawn wire varies widely, but the 6mm to 12mm range is particularly notable for its versatility and application across various sectors.

Manufacturing Process

The manufacturing of 6mm-12mm cold drawn wire involves several steps. Initially, larger wire rods are produced from steel or other metals, which then undergo a thorough inspection for quality assurance. Once deemed suitable, these rods are fed into a series of drawing machines. Each machine reduces the diameter of the wire incrementally, allowing for precise control over the final product's specifications. Additionally, lubrication is utilized during the drawing process to minimize friction and reduce wear on the dies, ensuring a consistent and defect-free output.

Quality control is paramount in cold drawn wire manufacturing. Factories implement various testing methods, including tensile tests, hardness tests, and surface inspection, to guarantee that the wire meets industry standards. For manufacturers that need wire within specific tolerances, the cold drawn wire process can achieve variations as fine as ±0.01mm, making it an ideal choice for precision engineering applications.

6mm-12mm wire gauge cold drawn wire factory

Applications of 6mm-12mm Cold Drawn Wire

The applications of cold drawn wire in the 6mm to 12mm range are vast and varied. One of the primary uses is in the automotive industry, where it is employed for producing components such as springs, bolts, and other fasteners that require exceptional strength and resistance to fatigue. The enhanced mechanical properties of cold drawn wire allow these components to withstand high stresses, making them essential for vehicle safety and performance.

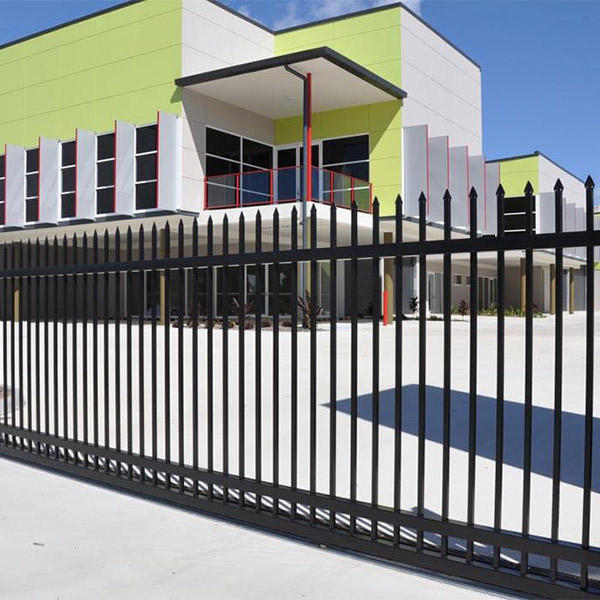

Moreover, the construction sector makes extensive use of cold drawn wire for reinforcement in concrete structures. The wire's tensile strength contributes to the durability of buildings, bridges, and other infrastructure. Additionally, manufacturers of wire mesh and fencing systems rely on cold drawn wire for its resilience and shape retention under various environmental conditions.

Manufacturers in the electrical industry also utilize 6mm to 12mm cold drawn wire for winding coils and producing electrical connectors. The smooth surface finish of the cold drawn wire minimizes the potential for electrical resistance, ensuring optimal performance in electrical applications.

Conclusion

In conclusion, the production of 6mm-12mm cold drawn wire is a vital component of many manufacturing processes across diverse industries. The benefits of cold drawing, including enhanced strength, superior surface finish, and precise tolerances, make this material an ideal choice for a wide range of applications, from automotive components to construction reinforcement. As industries continue to evolve and demand higher quality materials, cold drawn wire's role will undoubtedly become even more critical. For manufacturers looking for reliable and high-performance products, investing in cold drawn wire from reputable factories is a decision that will yield significant long-term benefits.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025