Nov . 12, 2024 18:24 Back to list

6mm-12mm wire gauge cold drawn wire factories

Understanding 6mm-12mm Wire Gauge Cold Drawn Wire Factories

The manufacturing of cold drawn wire has been a crucial aspect of various industries, providing essential raw materials for applications in construction, automotive, and electrical sectors. Among the types of cold drawn wires produced, the 6mm-12mm wire gauge range represents a significant size segment. This article explores the process, benefits, applications, and the characteristics of factories that specialize in manufacturing cold drawn wire within this gauge range.

What is Cold Drawn Wire?

Cold drawing is a metalworking process that involves pulling (or drawing) a metal wire through a series of dies to reduce its diameter and increase its length. This technique enhances the mechanical properties of the wire, primarily by improving its tensile strength and surface finish without the need for high-temperature processing. Cold drawn wires can be made from various materials, including steel, stainless steel, and even non-ferrous metals such as copper and aluminum.

The Process of Manufacturing Cold Drawn Wire

The production of cold drawn wire involves several key steps

1. Wire Rod Preparation The process begins with the procurement of wire rods that meet specific alloy and size requirements. For wires ranging from 6mm to 12mm in gauge, high-quality steel rods are often used.

2. Cleaning and Coating The wire rods are cleaned to remove any surface contaminants, and they may be coated with lubrication to facilitate the drawing process and prevent wear on the dies.

3. Drawing The cleaned wire rods are then drawn through a series of progressively smaller dies. Each pass through a die reduces the diameter of the wire while increasing its length. This step is crucial for achieving the desired final dimensions and mechanical properties.

4. Annealing After drawing, the wire might be subjected to annealing, a heat treatment process that improves ductility and reduces hardness, making the wire easier to work with.

5. Final Inspection and Quality Control Finished wires undergo rigorous quality control checks to ensure they meet specified standards in terms of diameter, tensile strength, and surface quality.

6. Coiling and Packaging The wires are then coiled into manageable forms and packaged for shipment to customers.

Benefits of Cold Drawn Wire

6mm-12mm wire gauge cold drawn wire factories

Cold drawn wire offers several advantages that make it desirable in many applications

- Enhanced Mechanical Properties The cold drawing process increases the tensile and yield strength of the wire, making it suitable for demanding applications.

- Improved Surface Finish Cold drawn wires typically exhibit a smooth and uniform surface, which is essential for applications where aesthetics or functionality is crucial.

- Versatility Wires within the 6mm-12mm gauge range can be tailored for various uses, from high-stress applications in construction to delicate tasks within springs and electronic components.

- Cost Efficiency The cold drawing process can be economically advantageous, providing high-quality products at competitive prices.

Applications of 6mm-12mm Cold Drawn Wire

The 6mm-12mm cold drawn wire finds extensive application across various industries

- Construction Used in structural applications, reinforcement bars, and cables, this wire provides strength and reliability in buildings and infrastructures.

- Automotive The automotive industry utilizes cold drawn wire for making springs, cables, and various components that require high strength and durability.

- Electrical Cold drawn wire is also essential in the electrical sector for wiring, connectors, and other components that require excellent conductivity and strength.

- Manufacturing Many manufacturing processes utilize cold drawn wire for producing parts, tools, and other mechanical components that require precision and resilience.

Conclusion

Cold drawn wire, particularly in the 6mm-12mm gauge range, plays an instrumental role in a wide range of applications across various industries. Factories that specialize in this manufacturing process are equipped with advanced technology and skilled personnel to ensure high-quality production. With its enhanced properties and versatility, cold drawn wire continues to be a preferred choice for manufacturers, contributing to innovation and performance in countless applications. As industries evolve and demand for high-quality materials grows, the importance of these factories and the products they create is set to increase, driving advancements in technology and methodologies within the manufacturing sector.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

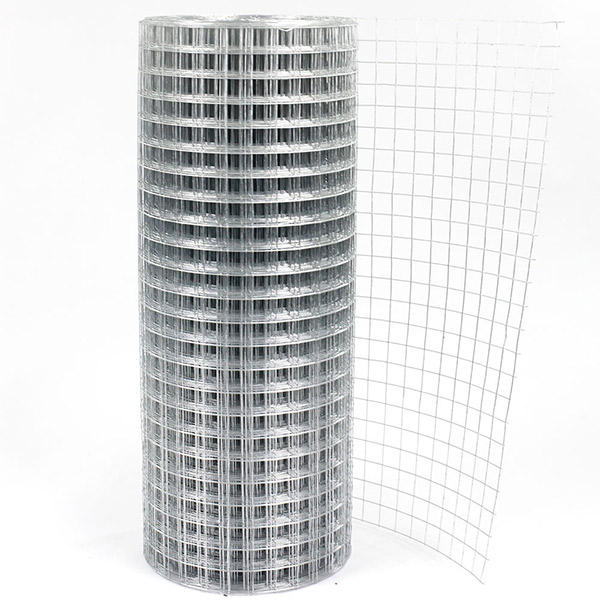

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025