Nov . 25, 2024 11:58 Back to list

5mm twisted square bar manufacturer

The Manufacturing Process of 5mm Twisted Square Bars

Twisted square bars, particularly those measuring 5mm, have become increasingly popular in various industries, including construction, automotive, and decorative applications. Their unique properties—combining aesthetic appeal with functional strength—make them a favored choice for a range of projects. This article will explore the manufacturing process behind these specialized components, shedding light on the intricacies of creating high-quality twisted square bars.

Understanding Twisted Square Bars

Twisted square bars are distinct from traditional square bars due to their unique twisted design. This twist not only enhances their visual appeal but also contributes to their structural strength. The 5mm size refers to the bar's cross-sectional width, which balances strength and flexibility, making it an ideal choice for multiple applications. These bars can be used for railings, architectural features, furniture, and even artistic installations.

Raw Materials The Foundation of Quality

The production of 5mm twisted square bars begins with the selection of raw materials. The most common material used is steel, prized for its strength, durability, and resistance to corrosion. Manufacturers often opt for different types of steel, such as stainless steel or galvanized steel, depending on the intended application. The integrity of these raw materials is vital, as it directly impacts the final product's performance.

The Manufacturing Process

The process of creating twisted square bars can be broken down into several key stages

1. Cutting and Shaping The initial step involves cutting long steel rods into the desired length. For 5mm twisted square bars, precision is crucial to ensure that each segment meets exact specifications. After cutting, the bars are shaped into a square cross-section through a process called hot rolling or cold drawing.

5mm twisted square bar manufacturer

2. Twisting Once the bars are cut and shaped, they undergo the twisting process. This is typically done using specialized machinery, which can precisely twist the bars at predetermined intervals. The twisting not only enhances the aesthetic quality of the bars but also increases the surface area, which can improve the bonding characteristics in applications such as welding or adhesive bonding.

3. Heating and Treatment After twisting, the bars may require heat treatment to enhance their mechanical properties. This process involves heating the bars to a specific temperature and then cooling them rapidly. Heat treatment can significantly improve the strength and ductility of the bars, making them suitable for more demanding applications.

4. Finishing The final steps in manufacturing twisted square bars involve finishing processes such as polishing, painting, or galvanizing. These processes help protect the bars from environmental factors such as moisture and oxidation, increasing their longevity. Aesthetic finishes may also be applied to enhance the bars' visual appeal, particularly for decorative applications.

Quality Control

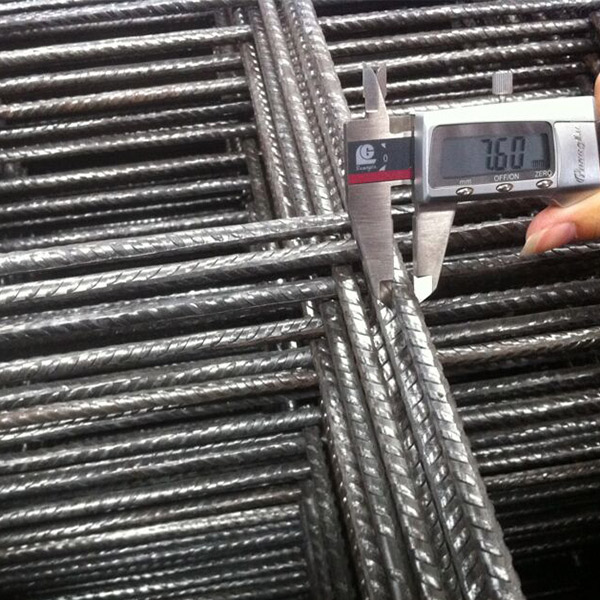

Throughout the manufacturing process, quality control is paramount. Manufacturers conduct rigorous inspections to ensure that each batch of 5mm twisted square bars meets industry standards and customer specifications. Tests may include measuring dimensions, assessing surface quality, and conducting tensile strength tests. These measures help to ensure that the final product is reliable and up to standard, addressing any deficiencies before the bars reach the market.

Applications of 5mm Twisted Square Bars

Due to their unique properties, 5mm twisted square bars are used in various applications. In construction, they are ideal for railings and fencing due to their strength and aesthetic appeal. In ornamental applications, they serve as striking design elements in furniture and fixtures. Additionally, within the automotive industry, these bars can be utilized in structural components that benefit from their twisted design.

Conclusion

The manufacturing of 5mm twisted square bars is a complex process that combines raw material selection, precise shaping, twisting, heat treatment, and finishing. Each stage is crucial in ensuring that the final product meets the high standards expected by different industries. As demand for these unique bars continues to grow, manufacturers remain committed to utilizing advanced techniques and stringent quality control measures to deliver outstanding results. Whether for functional or decorative purposes, the 5mm twisted square bar stands as a testament to both engineering excellence and aesthetic ingenuity.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025