Oct . 11, 2024 03:13 Back to list

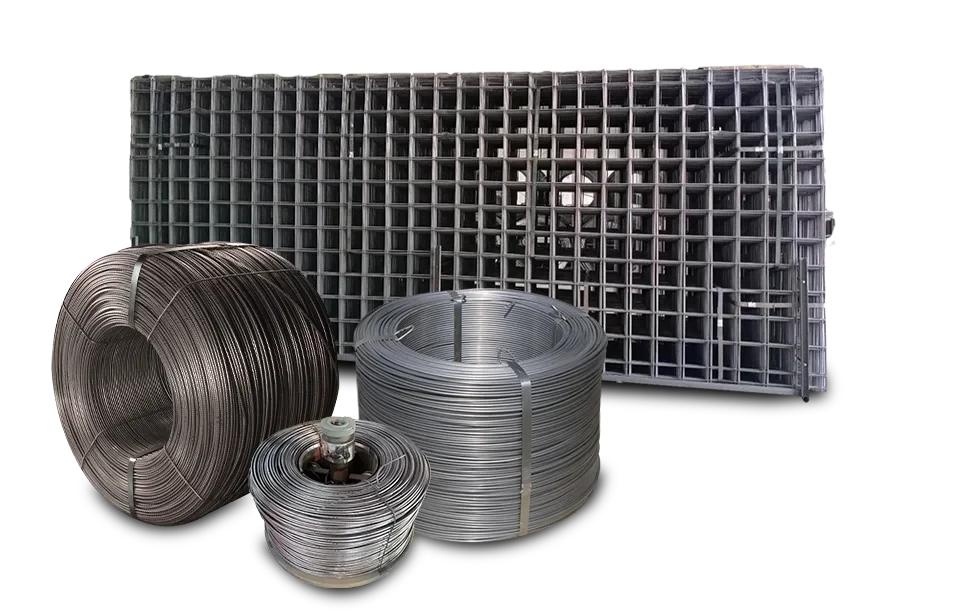

5mm*5mm 6mm*6mm 10mm*10mmhot sale reinforcing mesh

The Importance and Benefits of Reinforcing Mesh in Construction

In the realm of construction, the integrity and safety of structures are paramount. One essential component that has gained immense popularity due to its effectiveness and reliability is reinforcing mesh. Specifically, products like the 5mm x 5mm, 206mm x 6mm, and 10mm x 10mm sizes are hot items on the market for good reasons. This article outlines what reinforcing mesh is, its applications, advantages, and why these particular dimensions are increasingly favored by contractors and builders.

What is Reinforcing Mesh?

Reinforcing mesh, often referred to as wire mesh or welded wire fabric, consists of a grid of steel wires connected at regular intervals. This grid is typically produced in sheets or rolls, making it versatile for use in various construction projects. The mesh is designed to provide tensile strength and prevent cracking in concrete slabs, walls, and other structures. The use of mesh in reinforcement improves the load-bearing capacity and longevity of construction works.

Applications of Reinforcing Mesh

Reinforcing mesh is extensively used in various applications, including

1. Concrete Slabs It is commonly placed within concrete slabs to distribute loads evenly, reducing the risk of cracking and structural failure. The 5mm x 5mm mesh size works particularly well in residential applications.

2. Walls Whether it’s for retaining walls or facades, using reinforcing mesh ensures that the walls can withstand lateral pressures and other forces.

4. Fencing and Barriers Some mesh varieties serve a dual purpose; they not only reinforce concrete but can also act as a barrier or fencing solution.

5mm*5mm 6mm*6mm 10mm*10mmhot sale reinforcing mesh

5. Infrastructure Projects Larger dimensions like 10mm x 10mm are ideal for use in heavy infrastructure projects such as bridges and overpasses, where they encounter much more significant stress and strain.

Advantages of Using Reinforcing Mesh

The benefits of incorporating reinforcing mesh into construction projects are manifold

1. Increased Strength Reinforcing mesh distributes loads evenly across structures, significantly enhancing their strength. This is vital for long-lasting, resilient constructions.

2. Reduced Risk of Cracks With proper placement, reinforcing mesh can help in minimizing the chances of cracks forming in the concrete. Over time, this leads to lower maintenance costs and increased safety.

3. Ease of Use Reinforcing mesh is available in various dimensions, making it easy for contractors to choose the right size for their specific needs. The mesh can be easily cut and shaped on-site, facilitating a more efficient construction process.

4. Cost-Effectiveness Although the initial investment may seem substantial, reinforcing mesh contributes to lower long-term costs. The durability it provides can mean less frequent repairs and replacements down the line.

5. Versatility Available in numerous sizes, shapes, and material grades, reinforcing mesh can be used in a wide range of constructions—making it a versatile choice for different applications.

Conclusion

In conclusion, reinforcing mesh, particularly in sizes such as 5mm x 5mm, 206mm x 6mm, and 10mm x 10mm, plays a crucial role in enhancing the safety and durability of construction projects. Its benefits—ranging from increased strength to reduced risk of cracking—make it a staple in the industry. As construction techniques evolve and the demand for resilient infrastructures rises, the adoption of reinforcing mesh is set to grow, reinforcing its status as a smart investment for builders and contractors alike. By understanding the significance of this essential material, stakeholders in the construction industry can ensure they are making informed decisions that lead to safer and more reliable structures.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025