Nov . 05, 2024 06:14 Back to list

4 points double strand barbed wire manufacturers

The Emergence of 4% Double Strand Barbed Wire in the Manufacturing Industry

Barbed wire has been an essential component in security and fencing solutions for over a century. Its primary function is to deter intruders and secure perimeters. Among the various types of barbed wire manufactured today, the 4% double strand barbed wire has gained popularity for its unique features and benefits. This article explores the advantages and applications of 4% double strand barbed wire, as well as insights into the manufacturing process and key manufacturers in the industry.

Understanding 4% Double Strand Barbed Wire

4% double strand barbed wire refers to a type of fencing wire that consists of two strands twisted together, with barbs placed at regular intervals. The 4% indicates the percentage of carbon content, which enhances the tensile strength and durability of the wire. The design focuses on robustness, providing higher resistance to wear and tear, rust, and harsh environmental conditions.

The barbs are typically sharp and spaced out to create a formidable barrier against trespassers. In addition to its security features, this type of barbed wire is also lightweight, making it easier to handle and install compared to other fencing materials.

Advantages of 4% Double Strand Barbed Wire

1. Enhanced Security The design of double strands coupled with sharp barbs provides a formidable deterrent. It significantly reduces the likelihood of break-ins or unauthorized access, making it ideal for commercial properties, military installations, and agricultural settings.

2. Durability The 4% carbon content ensures that this barbed wire is exceptionally strong. It can withstand adverse weather conditions, making it suitable for outdoor applications without significant risk of degradation.

3. Cost-Effective Compared to alternatives like chain-link fences or wooden barriers, 4% double strand barbed wire is cost-effective. Its low maintenance requirements further enhance its value, as property owners spend less time and money on repairs or replacements.

4. Versatile Applications This type of barbed wire can be deployed in a variety of settings. From securing farms and ranches to protecting residential properties and commercial sites, its versatility allows it to serve multiple functions.

5. Ease of Installation The lightweight nature of 4% double strand barbed wire makes it relatively easy to install. It can be adapted to various fencing systems, including those that need to follow uneven terrain.

Manufacturing Process

The manufacturing of 4% double strand barbed wire involves several steps that ensure its quality and performance

.1. Material Selection High-quality steel with a specified carbon content is sourced to increase tensile strength.

4 points double strand barbed wire manufacturers

2. Wire Drawing The selected steel is drawn into thin strands through a series of dies to achieve the desired diameter.

3. Twisting Two strands are then twisted together to form the double strand. This process ensures that the wire has a strong helicoidal structure, resulting in an increased load-bearing capacity.

4. Barbing Sharp barbs are affixed at regular intervals along the wire. This is done using automated machinery for consistency and precision.

5. Galvanization The finished wire is coated with zinc to enhance its resistance to corrosion, allowing it to endure varying climates.

6. Quality Control Throughout the manufacturing process, strict quality checks are implemented to ensure that the final product meets industry standards.

Leading Manufacturers

Several manufacturers specialize in producing 4% double strand barbed wire, focusing on quality and customer satisfaction. Some notable players in the industry include

1. Clamcleat Ltd. Known for their high-quality fencing solutions, Clamcleat has been a trusted name in the barbed wire market for decades.

2. Maverick Wire With a commitment to innovation and sustainability, Maverick Wire has made a name for itself through its eco-friendly practices and durable products.

3. Bekaert A global leader in steel wire products, Bekaert produces a wide range of fencing solutions, including high-strength barbed wire used worldwide.

4. Hercules Wire Specializing in agricultural and security fencing, Hercules Wire provides robust options that cater to various customer needs.

Conclusion

The 4% double strand barbed wire is a vital component in modern fencing solutions, offering enhanced security, durability, and cost-effectiveness. As manufacturers continue to innovate and improve the production processes, this fencing option remains a reliable choice for a wide range of applications. With its ability to withstand harsh conditions while remaining adaptable for varied uses, 4% double strand barbed wire is poised to sustain its significance in the industry for years to come.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

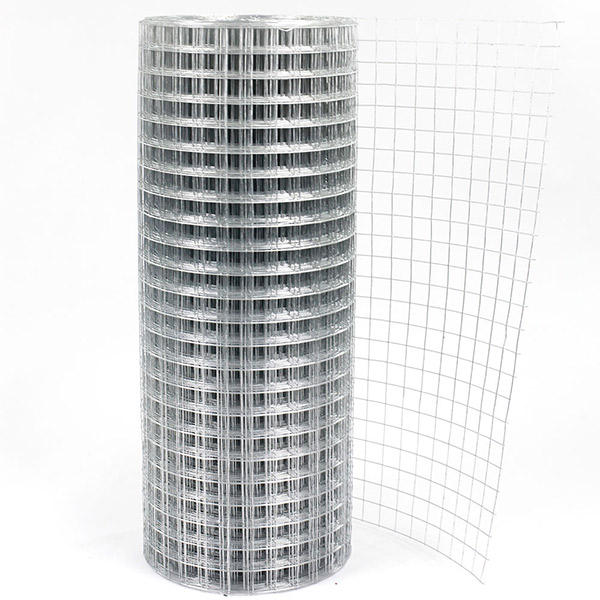

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025