Oct . 31, 2024 14:39 Back to list

Suppliers of 4mm Reinforced Steel Rebar for Construction Applications

The Importance of 4mm Reinforced Steel Rebar and Choosing the Right Suppliers

In the construction industry, the use of reinforced steel rebar is essential for ensuring structural integrity and durability. One such critical dimension used in various applications is the 4mm reinforced steel rebar. Despite its smaller diameter, 4mm rebar plays a significant role in lightweight constructions, such as residential buildings, precast concrete products, and various infrastructure projects. This article will explore the functionalities of 4mm rebar and provide guidance on selecting reliable suppliers.

Understanding 4mm Reinforced Steel Rebar

Rebar, short for reinforcing bar, is commonly used in concrete construction to enhance tensile strength. Concrete is exceptionally strong under compression but weak under tension; hence, incorporating rebar helps to bear loads and withstand voltage fluctuations. The 4mm diameter rebar is often employed in areas requiring less structural load, making it ideal for smaller-scale projects, decorative concrete, and thin slabs.

With its compatibility with various construction techniques, 4mm reinforced steel rebar can be found in applications such as ground slabs, pavements, and as support for precast products. It can also be shaped easily, allowing for intricate designs and patterns in concrete structures. Despite its size, 4mm rebar is made from high-quality steel, ensuring excellent durability, corrosion resistance, and long-term performance.

Selecting Reliable Suppliers

Choosing the right supplier for 4mm reinforced steel rebar is crucial to ensuring consistent quality in your construction projects. Here are some key factors to consider when selecting a supplier

4mm reinforce steel steel rebar suppliers

1. Quality Assurance Always inquire about the quality standards that the supplier adheres to. Rebar should meet relevant industry standards, such as ASTM or ISO certifications. Quality assurance guarantees that the rebar will perform as required, providing safety and reliability.

2. Experience and Reputation Opt for suppliers with a proven track record in the industry. Research their reputation among other construction companies and contractors. Online reviews, testimonials, and referrals can provide insight into their reliability and service quality.

3. Product Range A good supplier will offer a variety of rebar sizes, not only the 4mm one. This versatility allows you to source all necessary materials from a single supplier, streamlining your purchasing process and optimizing logistics.

4. Pricing and Value While cost is an essential factor, avoid solely focusing on the cheapest option. Assess the value offered by each supplier, including product quality, customer service, and delivery timelines. A slightly higher cost might yield better value and reliability in the long run.

5. Delivery Capabilities Confirm the supplier's ability to deliver materials promptly to your construction site. Timely deliveries can significantly impact project timelines and overall efficiency.

Conclusion

In summary, 4mm reinforced steel rebar is a crucial material in modern construction, especially for projects requiring lightweight support. By carefully selecting the right suppliers, construction companies can ensure the quality, safety, and efficacy of their structures. By focusing on quality assurance, reputation, product range, pricing, and delivery capabilities, you can find a trusted supplier that meets your project's needs and specifications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

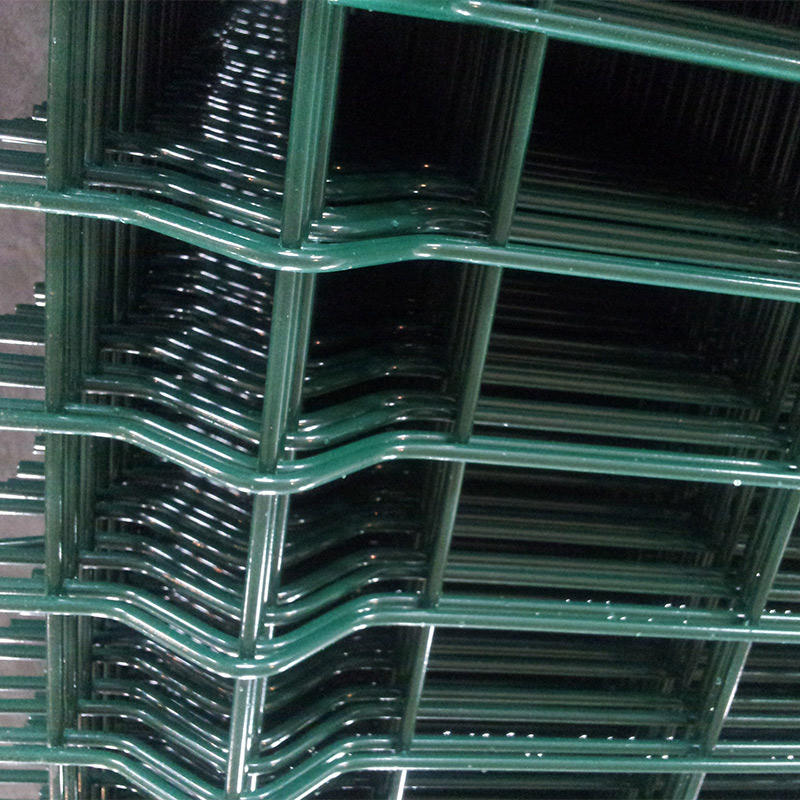

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025