Dec . 03, 2024 20:33 Back to list

4mm Reinforced Steel Rebar Supplier for Construction Projects and Structural Applications

Understanding 4mm Reinforced Steel Rebar A Comprehensive Guide

Reinforced steel, especially in the form of rebar, plays a crucial role in modern construction projects. Among the various sizes and types available, 4mm reinforced steel rebar stands out for its unique applications and benefits. This article explores the characteristics, uses, manufacturing process, and advantages of 4mm steel rebar, shedding light on why it is an essential component in structural engineering.

What is 4mm Reinforced Steel Rebar?

Reinforced steel bars, or rebar, are steel rods that provide tensile strength to concrete structures, which are naturally very good in compression but weak in tension. The 4mm size refers to the diameter of the rebar, making it a versatile option for various construction purposes, particularly in smaller-scale projects or detailed work. It is often used in applications where space is limited, or where precise reinforcement is necessary.

Manufacturing Process

The manufacturing of 4mm reinforced steel rebar involves several key steps. The process begins with the selection of high-quality steel, which is melted in a furnace. This molten steel is then cast into specific shapes and sizes, followed by a cooling process to solidify the material. After this, the steel undergoes a series of rolling processes to achieve the desired diameter of 4mm.

During the final stages of production, the rebar is treated to enhance its bonding capabilities with concrete. This is often achieved through surface deformations and coatings, which improve adhesion and corrosion resistance. Manufacturers may also carry out various tests to ensure that the rebar meets industry standards for strength and durability.

Applications of 4mm Reinforced Steel Rebar

4mm reinforce steel steel rebar manufacturer

4mm rebar is utilized in numerous construction scenarios. Due to its small diameter, it is particularly suited for

1. Concrete Slabs Frequently used in floor slabs, where consistent tensile strength is required over a large area without excessive weight. 2. Brick and Block Walls Provides additional reinforcement to masonry structures, helping improve their overall stability and load-bearing capacity. 3. Repair and Maintenance Ideal for reinforcing existing concrete structures where retrofitting is needed, especially in tight spaces. 4. Precast Concrete Elements Commonly used in the manufacturing of precast components like beams, columns, and panels, ensuring they can withstand various loads once installed.

5. Spliced Columns Ensures that the structural integrity of columns in buildings is maintained, particularly in seismic-prone areas.

Advantages of 4mm Reinforced Steel Rebar

One of the significant advantages of 4mm reinforced steel rebar is its flexibility in application. Its lightweight nature allows for easier handling and installation, making it an excellent choice for both small and large projects. Furthermore, the use of 4mm rebar can lead to cost savings in materials, as less steel is required for certain applications compared to larger diameters.

In addition, 4mm rebar exhibits good resistance to corrosion, especially when treated with appropriate coatings. This enhances the longevity of the structures where it is used, reducing the need for repairs and maintenance over time. The deformations on the rebar's surface also enhance the bond with concrete, leading to improved load distribution and overall structural performance.

Conclusion

In conclusion, 4mm reinforced steel rebar is an essential component in the construction industry, offering numerous benefits from flexibility to cost-effectiveness. Its adaptability in various applications—from slab construction to retrofitting—demonstrates its value to contractors and architects alike. As buildings continue to evolve in design and functionality, the significance of reliable and efficient reinforcement methods, such as 4mm rebar, cannot be overstated. When selecting the right materials for construction projects, understanding the role and advantages of 4mm reinforced steel rebar will undoubtedly contribute to more resilient and enduring structures.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

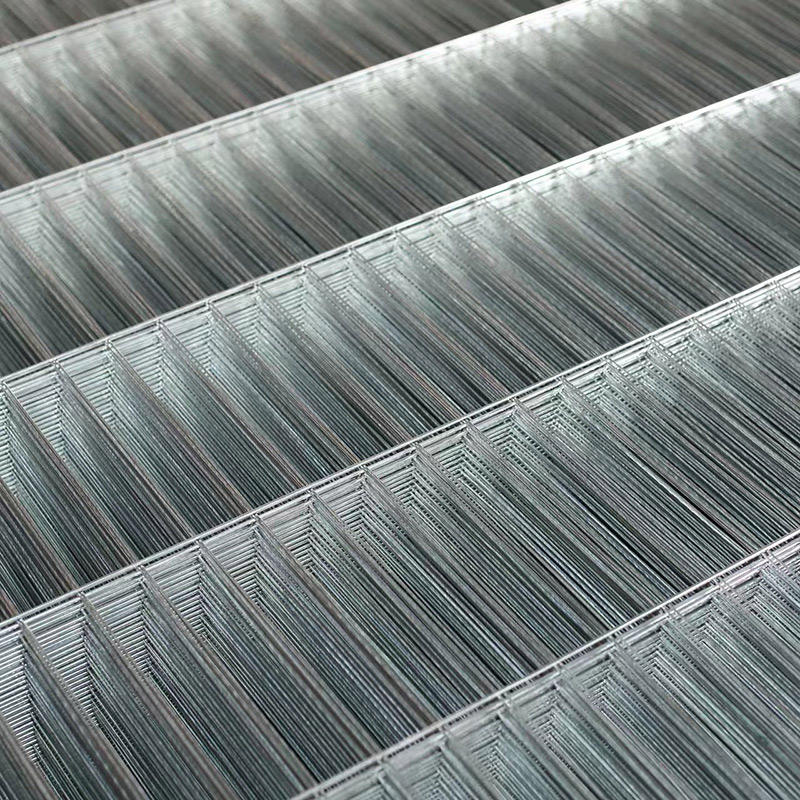

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025