Sep . 28, 2024 13:50 Back to list

Production of 4mm Reinforced Steel Rebar in Manufacturing Facilities

The Significance of 4mm Reinforced Steel Rebar in Construction

In the world of construction, the importance of using high-quality materials cannot be overstated. Among these materials, reinforced steel rebar, particularly the 4mm variety, plays a crucial role in ensuring the durability and strength of concrete structures. This article explores the significance of 4mm reinforced steel rebar, its manufacturing process, and its applications in the construction industry.

Understanding Reinforced Steel Rebar

Reinforced steel rebar, commonly known simply as rebar, is a steel bar or mesh used as a tensioning device in concrete structures. It provides additional tensile strength to the concrete, which is inherently weak in tension. The combination of concrete and steel creates a material that is strong, durable, and capable of withstanding various stresses.

The 4mm size of rebar is particularly appealing for specific applications, especially in lightweight construction, residential projects, and decorative work. Its smaller diameter makes it easier to handle, bend, and cut, making it an excellent choice for intricate designs and tighter spaces.

The Manufacturing Process

The manufacturing of 4mm reinforced steel rebar involves several critical steps. First, raw steel is melted in a furnace and then transformed into long bars through a process called extrusion. After the bars are formed, they undergo a cooling process to achieve the desired strength and ductility.

Once the bars are cooled, they are subsequently deformed to create surface ridges that enhance the bond between the rebar and the surrounding concrete

. This deformation is crucial because it increases the grip between the two materials, ensuring that they work together efficiently under load.4mm reinforce steel steel rebar factory

Quality control is an essential part of the manufacturing process. Testing for tensile strength, ductility, and corrosion resistance ensures that the rebar meets industry standards. Reputable factories emphasize the importance of adhering to these standards, as any shortcomings can lead to structural failures or safety hazards down the line.

Applications in Construction

The applications of 4mm reinforced steel rebar are vast and varied. In residential construction, it is often used in reinforced slabs, walls, and foundations, providing essential support to prevent cracking and deformation over time. Its lightweight nature makes it an ideal candidate for small-scale projects where heavy-duty reinforcement is unnecessary.

In decorative applications, 4mm rebar is used in artistic installations and landscape designs. Its flexibility allows for creative shapes and patterns that can enhance the aesthetic appeal of outdoor spaces. Additionally, it is commonly utilized in the fabrication of precast concrete products, such as fences and barriers.

4mm reinforced steel rebar is also important in infrastructure projects, especially in areas where weight considerations are critical. Bridges, tunnels, and overpasses frequently require careful balance regarding load, making this size of rebar exceptionally valuable.

Conclusion

In conclusion, the significance of 4mm reinforced steel rebar cannot be underestimated in the construction industry. It combines strength, versatility, and ease of handling, making it a preferred choice for various applications. The manufacturing processes that ensure its quality further enhance its reliability as a construction material.

As urbanization and construction projects continue to rise globally, the demand for high-quality materials, such as 4mm reinforced steel rebar, will only increase. Its ability to enhance the structural integrity of concrete makes it an indispensable component in building safe and durable infrastructures for the future. Investing in quality rebar not only ensures the longevity of structures but also contributes to the overall safety and stability of our built environment.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

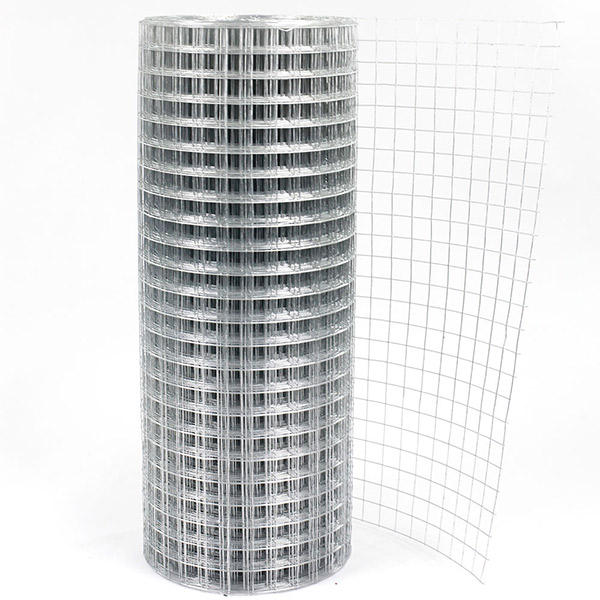

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025