Nov . 02, 2024 12:20 Back to list

4mm cold drawn wire manufacturers

The Emerging Landscape of 4mm Cold Drawn Wire Manufacturers

The manufacturing of cold drawn wire, particularly the 4mm variant, is becoming increasingly important in various industries due to its versatile applications and enhanced properties. As businesses look to optimize their production processes and improve product quality, 4mm cold drawn wire has emerged as a key material in sectors ranging from construction to automotive and even electronics.

Cold drawing is a metalworking process that involves pulling a wire through a die to reduce its diameter while increasing its length. This process enhances the physical properties of the wire, including its tensile strength, hardness, and surface finish. Manufacturers specializing in 4mm cold drawn wire are utilizing advanced technologies and techniques to meet the growing demand for high-performance materials.

Market Demand and Applications

The rising demand for 4mm cold drawn wire can be attributed to its wide range of applications. In the construction industry, it is often used for reinforcing concrete structures and producing high-strength cables. The automotive sector utilizes this wire in manufacturing various components, including springs, fasteners, and structural elements. Additionally, the electronics industry employs 4mm cold drawn wire in the production of components such as connectors and terminals due to its excellent electrical conductivity and mechanical properties.

Choosing the Right Manufacturer

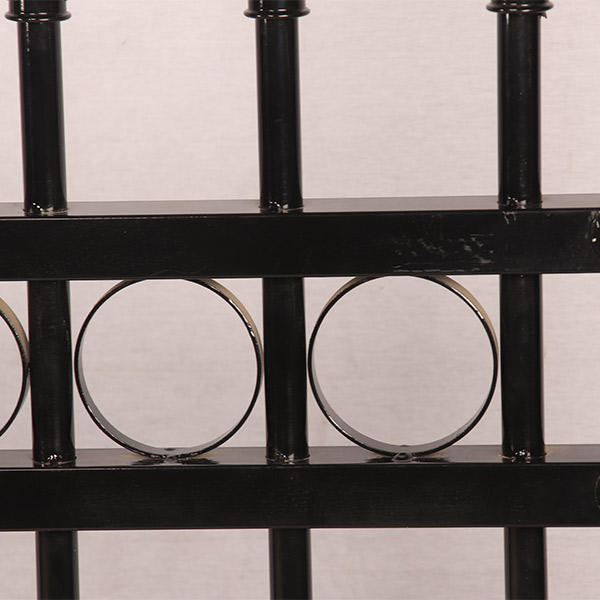

4mm cold drawn wire manufacturers

When selecting a manufacturer for 4mm cold drawn wire, several factors must be considered. Quality assurance is paramount; reputable manufacturers employ strict quality control measures throughout the production process to ensure that the wire meets specified standards. Certifications such as ISO 9001 are indicators of a manufacturer’s commitment to quality.

Moreover, manufacturers that invest in modern equipment and technologies tend to produce wire with superior characteristics. This includes better surface finishes and more consistent mechanical properties, which are essential for high-performance applications. Collaboration with manufacturers that offer customization options can also be beneficial, as this allows businesses to specify the exact properties required for their specific applications.

Sustainability Practices

Sustainability is an increasingly important consideration in manufacturing. Many 4mm cold drawn wire manufacturers are adopting environmentally friendly practices, such as using recyclable materials and minimizing waste in their production processes. By choosing a manufacturer committed to sustainability, companies not only enhance their own environmental credentials but also contribute to a greener future.

Conclusion

The landscape of 4mm cold drawn wire manufacturing is continually evolving, driven by technological advancements and increasing market demand. By understanding the applications, quality assurances, and sustainability practices associated with this industry, businesses can make informed decisions when selecting a manufacturer. In doing so, they can ensure they acquire the high-quality materials required to enhance their product offerings and maintain a competitive edge in their respective markets. As the industry grows, so too do the opportunities for innovation and collaboration among manufacturers and end-users alike.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025