Nov . 10, 2024 18:44 Back to list

3mm Galvanized Wire Production and Supply for Versatile Applications

The Importance of Choosing the Right 3mm Galvanized Wire Manufacturer

When it comes to industrial applications, choosing the right materials is paramount. One such material that has gained immense popularity is the 3mm galvanized wire. This versatile and durable wire is extensively used in various sectors, including agriculture, construction, and manufacturing. However, the quality and reliability of the wire largely depend on the manufacturer. In this article, we will discuss the critical aspects to consider when selecting a 3mm galvanized wire manufacturer, the benefits of galvanized wire, and the potential applications of this essential product.

Understanding Galvanized Wire

Galvanized wire is essentially steel wire that has undergone a coating process to protect against rust and corrosion. This coating is done by dipping the wire in molten zinc, creating a barrier between the steel and environmental factors that can cause deterioration. The galvanization process significantly enhances the lifespan of the wire, making it an ideal choice for outdoor applications or areas exposed to moisture.

When talking about 3mm galvanized wire, it’s important to recognize its specific dimensions and characteristics. This size is commonly used for various heavy-duty applications, as it provides the necessary tensile strength and durability. Whether it’s for fencing, construction, or supporting structures, 3mm galvanized wire offers a reliable and robust solution.

Factors to Consider When Choosing a Manufacturer

1. Quality Standards It is essential to choose a manufacturer that adheres to high-quality standards. Look for certifications that demonstrate compliance with international manufacturing processes and quality assurance protocols. This will ensure that the 3mm galvanized wire produced meets the required specifications for strength and durability.

2. Manufacturing Process Understanding the manufacturer’s fabrication process is critical. Investigate whether they use hot-dip galvanizing, which is generally more effective than electro-galvanizing for providing corrosion resistance. The methods employed in galvanizing can significantly impact the performance and longevity of the wire.

3mm galvanized wire manufacturer

3. Reputation and Experience A manufacturer’s reputation in the industry speaks volumes about the quality of their products. Research customer reviews and testimonials, and consider their experience in producing galvanized wire. Manufacturers with a longstanding presence are more likely to have perfected their processes and provide dependable products.

4. Customization Options Depending on your specific needs, you may require customized specifications for your galvanized wire. A manufacturer that offers customization in terms of length, coating thickness, and tensile strength can better serve your unique application requirements.

5. Cost and Value While it may be tempting to go for the cheapest option, it’s vital to balance cost with quality. Sometimes, investing a little more up front can save money in the long run through reduced maintenance and replacement costs. Ensure you understand the value proposition offered by the manufacturer.

Applications of 3mm Galvanized Wire

The applications of 3mm galvanized wire are vast and varied. In agriculture, it is frequently used for fencing livestock, as its durability ensures long-term functionality. In construction, the wire serves as an essential component for reinforcing concrete and creating supports. Additionally, industries such as shipping and manufacturing utilize 3mm galvanized wire for creating lifting slings, cargo nets, and various rigging solutions.

Conclusion

Choosing the right 3mm galvanized wire manufacturer is crucial to ensuring the success of your projects. By taking into account factors such as quality standards, manufacturing processes, reputation, customization options, and overall value, you can make an informed decision that meets your requirements. With the right manufacturer, you can be confident that you are investing in a product that not only meets industry standards but exceeds your expectations, providing the durability and reliability needed for various applications.

-

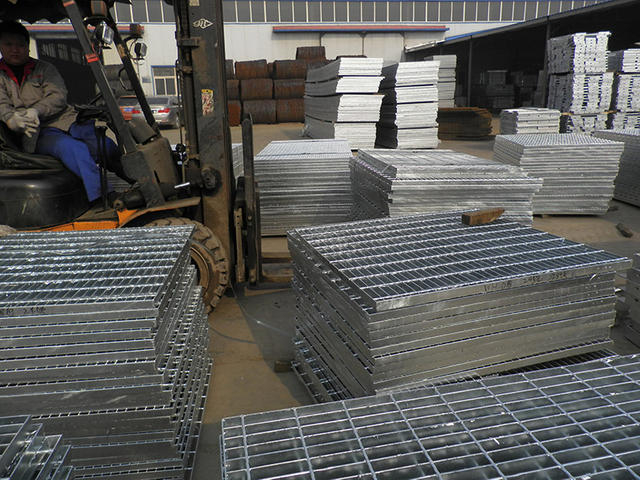

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025