Nov . 06, 2024 08:17 Back to list

2.5mm Galvanized Iron Wire Production and Suppliers for Various Applications

Understanding the Significance of 2.5mm Galvanized Iron Wire Manufacturers

Galvanized iron wire, known for its strength and durability, plays a crucial role in various industries and applications. Among the different diameters of galvanized wire, the 2.5mm variant is particularly popular due to its optimal balance between flexibility and strength. This article focuses on the significance of manufacturers producing 2.5mm galvanized iron wire, the benefits of using this material, and the factors to consider when choosing a manufacturer.

The Importance of 2.5mm Galvanized Iron Wire

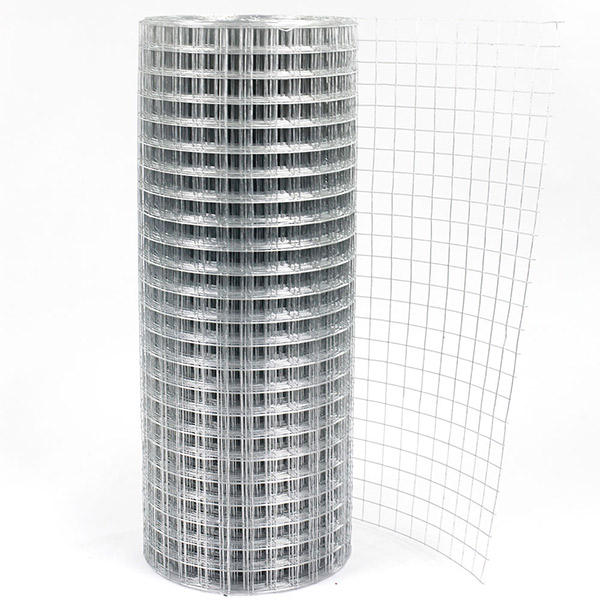

The 2.5mm galvanized iron wire is extensively used in construction, agriculture, fencing, and other applications where robust support is essential. Its galvanized coating provides excellent resistance to rust and corrosion, making it suitable for outdoor use where exposure to the elements is a concern. This wire is often utilized for creating fencing solutions, reinforcing concrete structures, crafting wire mesh, and various other applications that require a reliable and sturdy material.

Benefits of Galvanized Iron Wire

One of the primary advantages of using galvanized iron wire is its long lifespan. The galvanization process, which involves coating the iron wire with a layer of zinc, helps prevent oxidation. This feature makes the wire ideal for various environments, especially in humid or coastal areas where traditional iron would quickly deteriorate.

Another benefit is its versatility. The 2.5mm wire can be easily manipulated to suit different construction needs. It can be bent, twisted, or even welded, which provides a broad range of applications. Additionally, it offers high tensile strength, allowing it to withstand heavy loads and tough conditions without breaking or deforming.

Choosing the Right Manufacturer

When selecting a 2.5mm galvanized iron wire manufacturer, several factors should be taken into consideration to ensure quality and reliability.

2.5mm galvanized iron wire manufacturer

1. Reputation and Experience Look for manufacturers with a strong reputation in the industry. Those with years of experience are often more reliable, as they have established quality control processes and understand their customers’ needs.

2. Quality Certifications Ensure that the manufacturer adheres to industry standards and possesses relevant certifications. Quality certifications often indicate that the manufacturer meets specific benchmarks for their products.

3. Production Capacity Depending on your needs, the production capacity of the manufacturer is crucial. A capable manufacturer should be able to meet your demand within the required timelines.

4. Customization Options Some projects may require specific properties for the wire, such as different coatings or treatments. A manufacturer that offers customization can provide solutions tailored to your project’s needs.

5. Customer Service Reliable customer service can greatly enhance the purchasing experience. A responsive and knowledgeable customer service team can assist in addressing any query or issue promptly, ensuring smooth communication throughout the procurement process.

6. Pricing While price shouldn’t be the only consideration, it is essential to compare quotes from different manufacturers. Look for competitive pricing without compromising on quality.

Conclusion

In summary, 2.5mm galvanized iron wire is a vital material in various applications, offering excellent durability and resistance to corrosion. Choosing the right manufacturer is crucial to ensure that you receive a high-quality product that meets your needs. By considering factors such as reputation, certifications, production capacity, customization options, and customer service, you can make an informed decision that will benefit your project in the long run. With the right manufacturer by your side, you can harness the full potential of galvanized iron wire to achieve robustness and longevity in your applications.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025