Nov . 04, 2024 20:48 Back to list

1 x 1 welded wire mesh factories

The Role of 1% Welded Wire Mesh in Factories Innovations and Applications

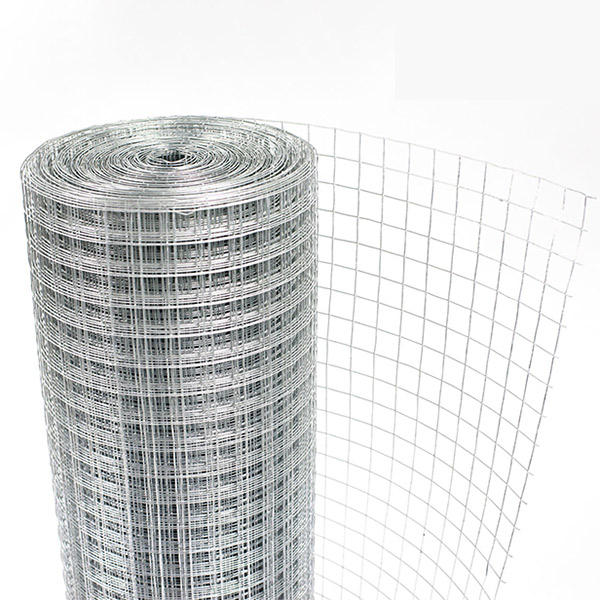

In today's industrial landscape, welded wire mesh plays a critical role in various applications, particularly within factory environments. Among the many specifications available, the 1% welded wire mesh has gained significant attention for its unique properties and versatility. This article explores the characteristics, manufacturing processes, and various applications of 1% welded wire mesh in factory settings.

Understanding 1% Welded Wire Mesh

Welded wire mesh is created by welding intersecting wires together at right angles to form a grid-like pattern. The “1%” designation refers to the percentage of materials used in the mesh composition, indicating a specific strength and durability tailored for industrial use. This type of mesh typically consists of high-quality steel wires, which are known for their robustness and structural integrity. The welding process ensures that the intersections are secure, providing enhanced stability and load-bearing capacities.

Manufacturing Process

The production of 1% welded wire mesh involves several crucial steps. First, high-quality wire is drawn to the desired diameter. The wires are then arranged in parallel and perpendicular orientations to form a grid. Advanced automated machinery is used to weld the wires at their intersection points, ensuring uniformity and strength throughout the mesh. After welding, the mesh is treated with protective coatings to enhance its corrosion resistance, making it suitable for various environmental conditions found in factories.

The manufacturing process is subject to strict quality control measures. Each batch undergoes rigorous testing to ensure that it meets the required specifications for tensile strength, flexibility, and resistance to wear and tear. This commitment to quality is vital for ensuring the mesh can withstand the demanding conditions found in manufacturing environments.

Applications in Factories

1 x 1 welded wire mesh factories

1. Safety Barriers and Fencing One of the primary applications of 1% welded wire mesh in factories is for safety barriers and fencing. The robustness of the mesh makes it ideal for creating secure perimeters around hazardous areas, preventing unauthorized access and protecting personnel from potential dangers. Additionally, it can be used to create enclosures for machinery, safeguarding operators from moving parts.

2. Storage Solutions Welded wire mesh is frequently employed in storage applications within factories. It is used to construct shelving units, bins, and pallets that allow for effective organization and storage of materials. The open structure of the mesh ensures good visibility and airflow, which are essential for maintaining optimal conditions for stored products.

3. Partitioning Spaces Factories often require the division of large spaces into smaller areas for various functions such as production, assembly, or quality control. 1% welded wire mesh can be used to create partitions that are not only functional but also maintain an open feel, allowing for easy supervision and communication among workers.

4. Conveyor Systems In production lines, welded wire mesh is utilized to create conveyor belts and supports. Its durability ensures that it can carry heavy loads, while the welded intersections provide stability during operation. This capability is crucial for maintaining efficiency in the manufacturing process.

5. Ventilation and Security Grilles Adequate ventilation is essential in factories to ensure a safe working environment. 1% welded wire mesh is often used in the design of ventilation systems and security grilles, as its open structure allows for air circulation while still providing a physical barrier against external elements.

Conclusion

The importance of 1% welded wire mesh in factory environments cannot be overstated. Its combination of strength, versatility, and cost-effectiveness makes it an invaluable material for various applications, from safety barriers to storage solutions. As industries continue to evolve and innovate, the demand for such robust materials will only grow. Factories looking to enhance their operational efficiency, safety, and organization should consider investing in quality welded wire mesh solutions. Ultimately, this material not only meets the diverse needs of modern factories but also contributes to a safer and more efficient workplace.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025