Nov . 09, 2024 02:08 Back to list

16 Gauge Black Annealed Wire Manufacturers and Suppliers for Various Applications

The Role of 16 Gauge Black Annealed Wire Factories in Modern Industry

In today’s fast-paced manufacturing landscape, the demand for reliable and high-quality materials has never been greater. Among these essential materials, wire products stand out due to their versatility and applications across various sectors. One noteworthy category is the 16 gauge black annealed wire, renowned for its strength, flexibility, and resistance to breakage. This article delves into the significance of black annealed wire factories, focusing on their production processes, applications, and impact on various industries.

Understanding Black Annealed Wire

Black annealed wire is a type of wire that undergoes a special heat treatment process, known as annealing. This process softens the wire, making it more malleable and easier to work with. The term black refers to the coating that forms during oxidation, giving the wire a distinctive dark appearance. The 16 gauge designation refers to the thickness of the wire, with thicker gauges providing greater strength and durability.

Production Processes in Factories

The factories producing 16 gauge black annealed wire utilize a range of sophisticated machinery and techniques to create high-quality products. The production process typically begins with the selection of raw materials, often made from low-carbon steel due to its ideal blend of strength and flexibility. The wire is drawn to the desired thickness using drawing machines, followed by the annealing process, which involves heating the wire in a controlled environment and then cooling it gradually. This step is crucial, as it alters the wire's microstructure, enhancing its properties.

Quality control is an integral part of the manufacturing process. Factories conduct extensive tests to ensure that the wire meets industry standards in terms of tensile strength, elasticity, and resistance to corrosion. These checks are essential not only for customer satisfaction but also for ensuring the safety and longevity of the end products that utilize the wire.

Applications of 16 Gauge Black Annealed Wire

16 gauge black annealed wire factories

The versatility of 16 gauge black annealed wire makes it suitable for a wide array of applications. In the construction and building industries, it is often used for tying rebar in concrete structures, providing the necessary strength and support required for safe construction. Additionally, its flexibility allows for easy handling and manipulation, making it an ideal choice for various binding and tying applications.

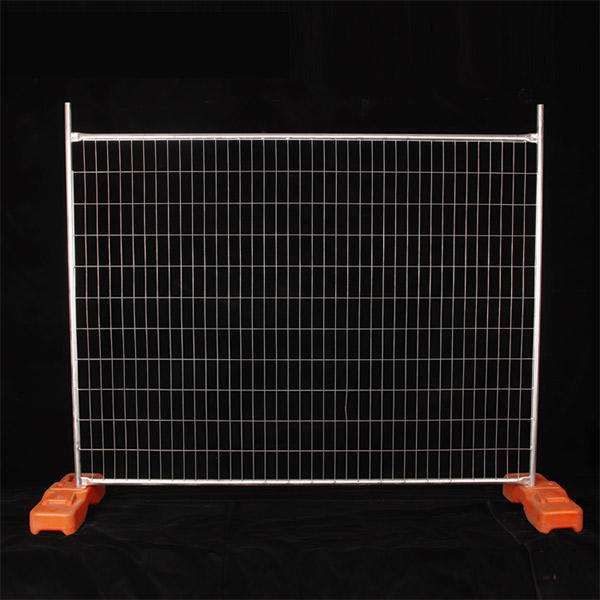

In the agricultural sector, black annealed wire is used for fencing and other support structures. Farmers and ranchers value the wire for its durability and resistance to weathering, which is crucial for the longevity of fences and trellises. Moreover, the wire is often employed in the crafting of wire mesh, which has applications in animal enclosures and garden netting.

The manufacturing sector also benefits from the use of 16 gauge black annealed wire. It is commonly found in the production of wire products such as hangers, brackets, and other supporting structures that require a reliable material. Additionally, the wire is used in the automotive industry for various applications, from suspension components to interior fittings.

Economic Impact and Job Creation

The significance of 16 gauge black annealed wire factories extends beyond the production of wire itself. These factories play a crucial role in local economies, providing jobs and contributing to community development. Skilled workers are needed to operate machinery, conduct quality control, and manage production processes. Moreover, the factories often source raw materials and services from local suppliers, further boosting the economy.

As demand for black annealed wire continues to grow, these factories are positioned to adapt and innovate. Advances in manufacturing technology, such as automation and enhanced quality control systems, promise to improve efficiency and product consistency, ensuring that factories remain competitive in a global market.

Conclusion

16 gauge black annealed wire factories play an indispensable role in various industries by providing reliable and versatile materials. Through advanced production techniques and rigorous quality control measures, these factories ensure that the wire meets the demands of modern applications, from construction to agriculture and manufacturing. As these industries continue to evolve, the significance of black annealed wire and the factories that produce it will undoubtedly grow, highlighting the continual need for quality materials in shaping our world.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025