Nov . 26, 2024 03:43 Back to list

10mm steel bar welded wire mesh manufacturers

Understanding the Importance of 10mm Steel Bar Welded Wire Mesh

In the construction industry, the safety, durability, and efficiency of structures are paramount. One of the essential materials that contribute to these aspects is welded wire mesh, specifically that made from 10mm steel bars. This type of mesh is becoming increasingly popular among manufacturers and construction professionals for several reasons.

What is Welded Wire Mesh?

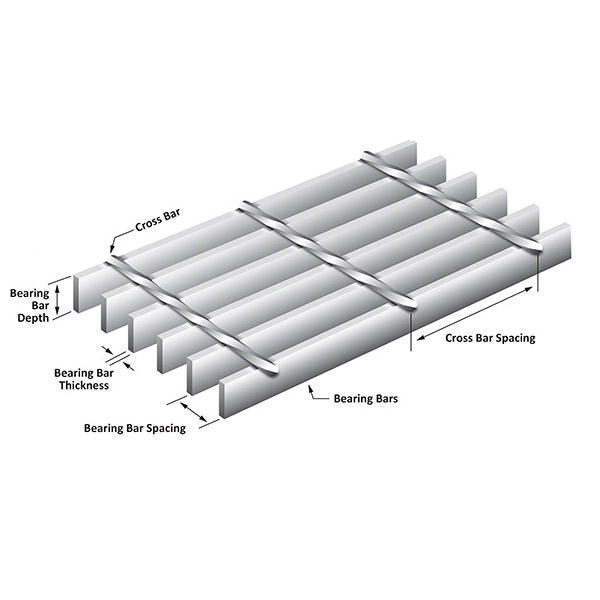

Welded wire mesh consists of a series of intersecting steel wires that are welded together at each junction, forming a robust grid. The 10mm steel bars provide significant strength and load-bearing capacity, making this mesh suitable for various applications, from residential buildings to industrial projects.

Advantages of 10mm Steel Bar Welded Wire Mesh

1. Strength and Durability One of the most compelling reasons for using 10mm steel bars in welded wire mesh is their exceptional strength. This thickness allows the mesh to withstand heavy loads, making it ideal for reinforced concrete applications. Whether used in floors, walls, or slabs, this welded wire mesh can significantly enhance structural integrity.

2. Cost-Effective Solution While the upfront cost for 10mm steel bar welded wire mesh may be higher than some alternatives, the long-term benefits outweigh these initial expenses. The durability of the steel reduces the need for frequent repairs or replacements, leading to cost savings over time. Additionally, the quick installation process saves labor costs and time on site.

3. Versatility Welded wire mesh is not limited to one application. Its versatility allows it to be used in various construction projects, including highways, bridges, and parking lots. Furthermore, it is also utilized in agricultural projects, such as fencing and animal enclosures, demonstrating its broad utility.

10mm steel bar welded wire mesh manufacturers

4. Improved Concrete Bonding One of the critical roles of weld mesh is to improve the bonding between the concrete and the mesh itself. This bonding is vital for the overall performance of the structure as it allows for better distribution of loads, reducing the chances of cracks and structural failure.

5. Resistance to Corrosion Many manufacturers offer 10mm steel bar welded wire mesh treated with protective coatings, such as galvanization. This treatment enhances the mesh's resistance to corrosion, making it suitable for outdoor and extreme environment applications, prolonging its lifespan considerably.

The Manufacturing Process

The manufacturing of 10mm steel bar welded wire mesh involves several critical steps. First, high-quality steel rods are sourced to ensure that the final product meets required standards. These rods are then cut into specific lengths before being arranged in a grid pattern. Advanced welding technology fuses the bars at each intersection, resulting in a strong and stable mesh. Finally, the mesh undergoes quality checks to ensure it meets construction codes and customer specifications.

Choosing the Right Manufacturer

When selecting a manufacturer for 10mm steel bar welded wire mesh, it is essential to consider a few key factors. Quality certifications, production capacity, and industry experience are crucial indicators of a reliable manufacturer. It's also beneficial to read customer reviews and ask for references to gauge the reputation of the manufacturer.

Conclusion

10mm steel bar welded wire mesh offers a robust and versatile solution for various construction needs. Its strength, durability, and cost-effectiveness make it an indispensable material in the building industry. As the demand for reliable construction materials continues to rise, the importance of high-quality welded wire mesh cannot be overstated. Investing in this product is not just about meeting current needs; it is about ensuring lasting safety and efficiency for future projects.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025