Dec . 10, 2024 03:24 Back to list

High-Quality 20mm Cold Drawn Wire Offered by Leading Supplier in the Market

The Growing Demand for 10% Cold Drawn Wire A Comprehensive Overview

In recent years, the metal industry has experienced significant changes, driven by advancements in technology and evolving market demands. Among these changes, cold drawn wire has carved out a niche of its own, with 10% cold drawn wire emerging as a popular choice among manufacturers and suppliers. This article discusses the characteristics, benefits, applications, and importance of sourcing from reliable suppliers.

What is Cold Drawn Wire?

Cold drawn wire is produced by drawing metal through a series of dies at room temperature, resulting in a product that has increased tensile strength, improved surface finish, and tighter tolerances when compared to wire that has been drawn at elevated temperatures. The 10% refers to the percentage decrease in the diameter of the wire during the drawing process. This reduction in diameter enhances the mechanical properties of the wire, making it suitable for various applications in different industries.

Characteristics and Benefits

The primary features of 10% cold drawn wire include higher tensile strength, superior surface quality, and excellent uniformity. The cold drawing process also allows for the creation of finer diameters and stronger wire without compromising its integrity.

Some key benefits of using 10% cold drawn wire are

1. Improved Mechanical Properties The cold drawing process induces strain hardening, resulting in enhanced strength and durability.

2. Enhanced Precision Cold drawn wire is manufactured to tight tolerances, making it suitable for applications that require precise dimensions.

3. Superior Surface Finish The cold drawing process produces a smoother surface, which is critical for applications where aesthetics and functionality are essential.

4. Versatility 10% cold drawn wire can be produced in various materials, including steel, stainless steel, and alloy wire, allowing for its use in diverse sectors.

Applications

10 mm cold drawn wire supplier

The applications of 10% cold drawn wire are vast and span multiple industries, including

- Automotive Industry It is used for making components like springs, wire rope, and safety features, where strength and fatigue resistance are crucial. - Construction Sector Cold drawn wire serves as reinforcement in concrete structures, as well as in the production of nails and fasteners.

- Manufacturing and Fabrication 10% cold drawn wire is commonly utilized in making wire products such as mesh, fences, and specialty wire goods.

- Electrical and Electronics Due to its conductivity properties, it is utilized in various electrical applications, such as windings and connectors.

Choosing the Right Supplier

The success of any project utilizing 10% cold drawn wire heavily relies on the quality of the material. Therefore, selecting a reputable supplier is paramount. Here are some factors to consider when making a choice

1. Quality Assurance Ensure that the supplier adheres to strict quality control measures and holds relevant certifications, such as ISO or ASTM standards.

2. Technical Expertise A knowledgeable supplier can offer insights into selecting the right type of wire for specific applications, assisting clients in making informed decisions.

3. Customization Options A good supplier should provide customization options regarding diameter, material, and mechanical properties to meet specific project needs.

4. Reputation and Reviews Research the supplier's track record within the industry. Customer reviews and testimonials can provide insight into their reliability and product quality.

5. After-Sales Support A supplier that offers exceptional after-sales support can be extremely beneficial, ensuring any issues are resolved promptly and efficiently.

Conclusion

As industries continue to evolve, the demand for high-quality materials like 10% cold drawn wire will only grow. With its remarkable properties and varied applications, this product has become a staple in many sectors. Choosing the right supplier is crucial for ensuring quality and reliability, ultimately leading to the success of various manufacturing processes. As we look to the future, the role of 10% cold drawn wire in the global market is set to expand even further, presenting new opportunities for industries across the board.

-

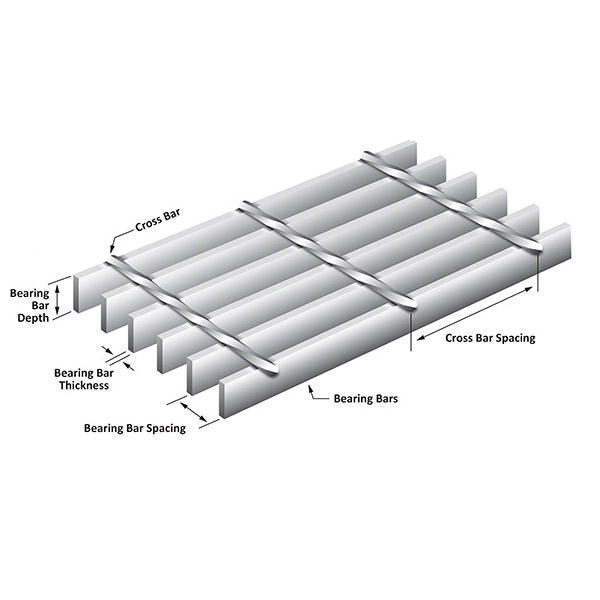

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025