Nov . 04, 2024 18:46 Back to list

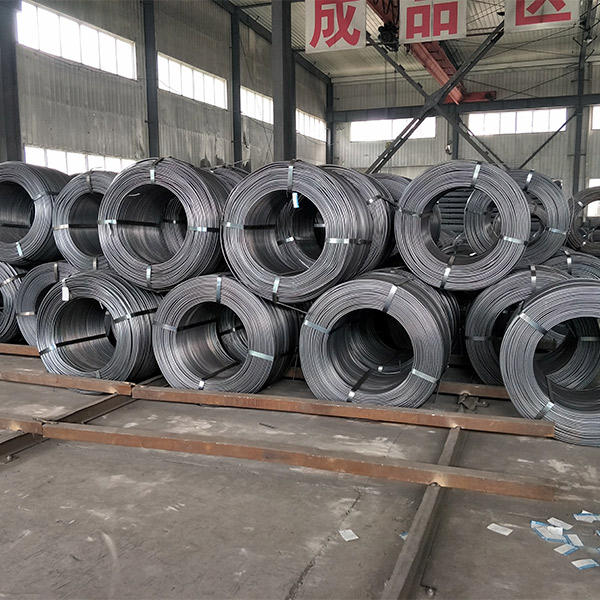

10 mm Cold Drawn Wire Suppliers for Quality Manufacturing Solutions and Applications

Understanding the Market for 10% Cold Drawn Wire Manufacturers

In the manufacturing sector, cold drawn wire plays a pivotal role across various industries due to its unique properties and advantages. One specific category that has garnered attention is the 10% cold drawn wire. This article explores the characteristics, applications, and market dynamics surrounding 10% cold drawn wire manufacturers.

What is Cold Drawn Wire?

Cold drawn wire is produced through a process that involves drawing the wire through a series of dies to decrease its diameter and increase its length. This process strengthens the metal through work hardening while improving its surface finish. Cold drawing is performed at room temperature, making it a preferred option for achieving precise dimensions and superior mechanical properties.

The Significance of 10% Cold Drawn Wire

The term 10% cold drawn wire typically refers to wire that has been reduced in diameter by approximately 10% from its initial size through the drawing process. This slight reduction may seem insignificant, but it can have substantial effects on the wire's mechanical properties, including tensile strength and ductility.

Applications of 10% Cold Drawn Wire

10% cold drawn wire is widely utilized in various applications, including

1. Automotive Industry This wire is commonly used in the manufacturing of components such as springs, cables, and connectors, where tensile strength and reliability are critical.

2. Construction Sector In the construction industry, it serves as reinforcement in concrete structures and is used in the production of welded wire mesh, enhancing the durability of buildings.

3. Electrical Industry Cold drawn wire is essential in producing electrical connectors and other components that require high conductivity and resilience.

4. Manufacturing of Fasteners Many fasteners, such as bolts and screws, utilize cold drawn wire due to its strength and ability to withstand fatigue.

5. Textile Industry In textiles, cold drawn wire is often used to produce various tools and machines that require precision and strength.

The Manufacturing Process

The process of manufacturing 10% cold drawn wire involves several steps, including

10 mm cold drawn wire manufacturers

1. Wire Rod Preparation The process starts with wire rods made from high-quality steel. These rods undergo initial inspection and cleaning to remove impurities.

2. Drawing The rods are drawn through a series of dies that reduce their diameter and increase their length. This is where the 10% reduction takes place. The drawing process must be meticulously controlled to achieve the desired dimensions and mechanical properties.

3. Annealing Once the desired diameter is achieved, the wire may undergo annealing, a heat treatment process that helps relieve internal stresses caused by drawing. This step enhances the wire’s ductility, making it easier to work with in further applications.

4. Finishing Operations The cold drawn wire is then cut to the required lengths and may undergo additional surface treatments, such as coating or galvanization, to improve corrosion resistance.

Market Dynamics

The global market for cold drawn wire, particularly the 10% cold drawn variety, is influenced by various factors

- Demand from End-User Industries The growth of the automotive and construction sectors directly correlates with the demand for cold drawn wire. As these industries expand, so does the need for reliable wire manufacturers.

- Technological Advancements Innovations in manufacturing techniques and materials have enabled manufacturers to produce wire that meets specific requirements for different applications, enhancing their competitive edge.

- Sustainability Trends As industries increasingly prioritize sustainability, manufacturers are adopting eco-friendly practices in production. This includes utilizing recycled materials and reducing energy consumption during the manufacturing process.

- Market Competition The presence of numerous manufacturers leads to competitive pricing and innovation, driving quality improvements and expanding the product range available to consumers.

Challenges Faced by Manufacturers

While the market for 10% cold drawn wire is promising, manufacturers face challenges such as fluctuating raw material prices, compliance with stringent regulations, and maintaining product quality amidst increasing production demands.

Conclusion

In summary, 10% cold drawn wire manufacturers play a critical role in supplying various industries with high-performance wire products. Understanding the features and market dynamics of this specialized wire is essential for industry stakeholders looking to meet consumer demands while navigating challenges in the global market. As manufacturing techniques continue to evolve, the future of cold drawn wire looks bright, with potential for innovations that will enhance its applications further.

-

High-Quality Steel Grating Solutions for Industrial Applications | Durable, Safety, Customization

NewsJul.13,2025

-

Advanced Solutions-CompanyX|Enterprise Efficiency&Cost Reduction

NewsJul.13,2025

-

Sustainable Manufacturing-EcoTech Innovations|Waste-to-Energy System&Zero Emissions

NewsJul.13,2025

-

Welded Wire Mesh- Buildings Wiremesh Co., Ltd.|Durable Construction Material&Industrial Strength Solution

NewsJul.13,2025

-

Smart Production Solutions-Example Corp|AI Automation&IoT Monitoring

NewsJul.13,2025

-

Advanced Industrial Solutions-Advanced Industrial Solutions|Manufacturing Efficiency&Productivity

NewsJul.13,2025