Dec . 19, 2024 09:25 Back to list

10 mm cold drawn wire manufacturer

The Rise of 10% Cold Drawn Wire Manufacturers A Detailed Overview

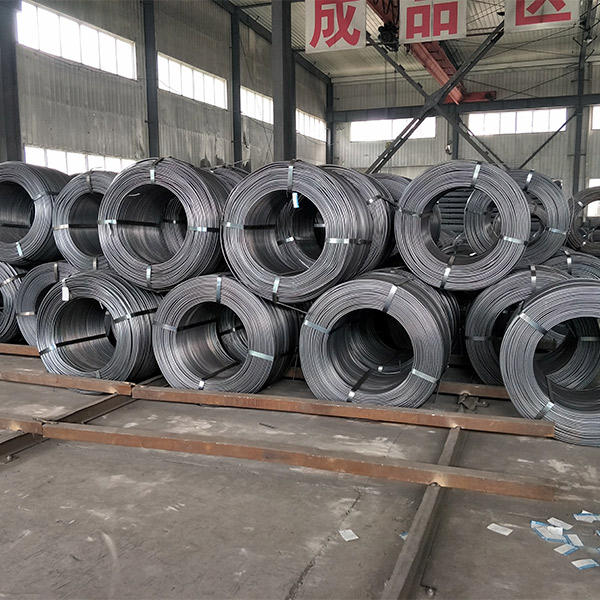

In recent years, the demand for high-quality cold drawn wire has surged across various industries, including automotive, construction, and electronics. Among the various specifications available in the market, 10% cold drawn wire has emerged as a preferred choice due to its unique characteristics and versatility. This article aims to explore the significance of 10% cold drawn wire manufacturers, shedding light on their production processes, applications, and the technological advancements that drive their success.

Understanding Cold Drawing

Cold drawing is a metalworking process that involves pulling a wire through a series of dies to reduce its diameter and increase its length. This method not only enhances the wire's tensile strength but also improves its surface finish and dimensional accuracy. The term 10% refers to the specific reduction of cross-sectional area that these wires undergo during the drawing process. This reduction is crucial as it enhances the mechanical properties of the wire, making it suitable for demanding applications.

The Production Process

The production of 10% cold drawn wire starts with selecting high-quality raw materials, typically low-carbon or high-carbon steel. These materials are then subjected to various pre-treatment processes, such as cleaning and annealing, to remove impurities and enhance ductility. The annealed wire is then drawn through multiple dies, with each die progressively reducing the diameter until the desired specifications are achieved.

The process of cold drawing itself is highly technical; it requires careful control of parameters such as drawing speed, lubrication, and die design. Manufacturers often employ advanced technology and machinery to ensure high precision and efficiency. The end result is a wire that not only meets rigorous industrial standards but also offers superior performance characteristics.

Applications of 10% Cold Drawn Wire

10% cold drawn wire has a wide range of applications across various sectors. In the automotive industry, it is commonly used for making suspension springs, engine components, and wire harnesses, all of which require high strength and durability. In the construction sector, this type of wire is utilized in reinforcing concrete, manufacturing nails, and producing mesh for various structural applications.

10 mm cold drawn wire manufacturer

Electronics also benefit from the use of 10% cold drawn wire. It is often found in the production of connectors, coils, and other components that require exceptional conductivity and reliability. The versatility of this wire extends to the manufacturing of musical instruments and even medical devices, where precision and quality are paramount.

Technological Advancements

The landscape of cold drawn wire manufacturing is constantly evolving, driven by technological advancements. Innovations such as automated drawing machines and computer-controlled processes have significantly improved production efficiency and precision. Additionally, the integration of advanced quality control systems ensures that each batch of 10% cold drawn wire meets stringent industry standards.

Moreover, the adoption of eco-friendly practices in manufacturing processes has become increasingly important. Manufacturers are now investing in sustainable practices, such as recycling water used in cooling systems and employing energy-efficient machinery. These initiatives not only reduce the environmental footprint but also benefit manufacturers through cost savings and improved public perception.

Challenges and Future Outlook

Despite the promising growth in the 10% cold drawn wire market, manufacturers face several challenges. Fluctuations in raw material prices, coupled with increasing competition, can impact profit margins. Additionally, the need for continuous innovation necessitates ongoing investment in research and development.

Looking ahead, the future of 10% cold drawn wire manufacturing appears bright. As industries increasingly demand higher quality materials, manufacturers that prioritize innovation and sustainability will likely thrive. The expanding applications of cold drawn wire in emerging technologies, such as electric vehicles and renewable energy, present significant opportunities for growth.

Conclusion

In conclusion, the role of 10% cold drawn wire manufacturers is vital in today's industrial landscape. Through advanced production techniques and a commitment to quality, these manufacturers are meeting the diverse needs of various sectors. As technology continues to advance and sustainability becomes a more pressing concern, the industry is poised for significant growth, marking an exciting era for manufacturers and consumers alike. By leveraging their expertise and embracing innovation, 10% cold drawn wire manufacturers are set to provide essential solutions that drive the economy forward.

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025