8 сар . 11, 2025 10:00 Back to list

High-Quality Welded Wire Mesh for Industry Factory Direct

The Foundation of Industrial Operations: Welded Wire Mesh

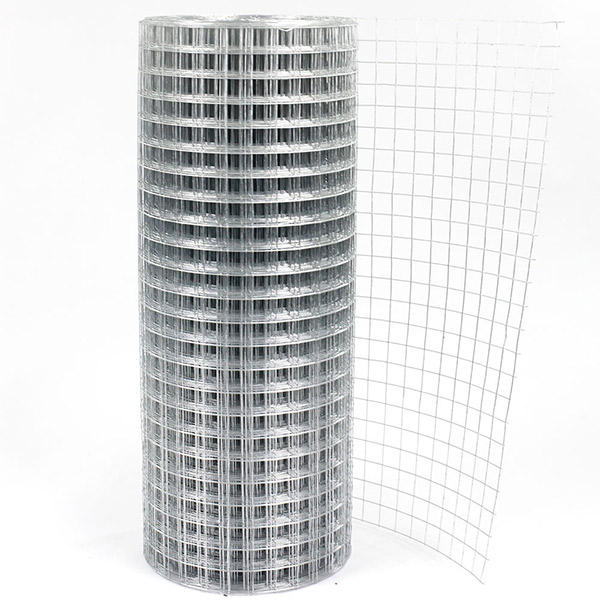

In the demanding landscape of modern industrial operations, the selection of robust and reliable materials is paramount. Welded wire mesh for industry factory applications stands as a critical component, offering unparalleled structural integrity and versatility. From heavy-duty construction and safety enclosures to filtration systems and architectural design elements, its unique properties provide a foundational solution for diverse industrial needs. This material, characterized by its precise grid patterns and strong welded joints, ensures optimal performance under various stresses, making it indispensable for factories and industrial facilities seeking long-term reliability and efficiency. Understanding its manufacturing intricacies, technical specifications, and broad utility is key for procurement specialists and engineers considering welded wire mesh for industry factory installations.

Leading welded wire mesh for industry manufacturers are continuously innovating, adapting production techniques to meet the evolving demands of sectors like petrochemical, mining, wastewater treatment, and construction. The emphasis is increasingly on specialized alloys, enhanced corrosion resistance, and optimized mechanical properties to withstand extreme environmental conditions and operational loads. As industries push the boundaries of efficiency and sustainability, the role of high-quality welded wire mesh becomes even more pronounced, serving as a silent, yet crucial, enabler of productivity and safety across numerous applications.

Industry Trends and Technological Advancements in Welded Wire Mesh Production

The market for industrial wire mesh is experiencing significant shifts driven by automation, material science breakthroughs, and a heightened focus on environmental sustainability. Modern welded wire mesh for industry factories are adopting advanced robotics and AI-driven quality control systems to ensure precision and consistency, minimizing human error and maximizing output. This technological integration allows for the production of highly customized mesh sizes and configurations, meeting the precise demands of niche industrial applications such as specialized filtration for chemical processing or high-security perimeters in critical infrastructure. Furthermore, the development of new alloy compositions, including high-strength stainless steels and galvanized variants, offers superior performance characteristics, notably enhanced resistance to corrosion, extreme temperatures, and abrasive environments.

Another prominent trend is the increasing demand for sustainable manufacturing practices. Leading welded wire mesh for industry suppliers are investing in energy-efficient production processes, utilizing recycled materials where feasible, and optimizing supply chains to reduce their carbon footprint. This commitment to sustainability not only aligns with global environmental initiatives but also offers economic benefits through reduced resource consumption and waste generation. These advancements collectively contribute to a more resilient, efficient, and environmentally responsible industrial sector, solidifying the role of welded wire mesh for industry factory applications as a future-proof material solution.

Manufacturing Excellence: The Welded Wire Mesh Process and Quality Standards

The production of welded wire mesh for industry factories is a meticulously controlled process designed to yield products of exceptional strength and uniformity. It begins with the selection of high-grade raw materials, typically low-carbon steel wire, stainless steel wire (e.g., SS304, SS316), or galvanized wire, chosen based on the intended application's environmental and mechanical demands. The wires are then straightened and cut to precise lengths. The core of the manufacturing process involves an automated welding machine, where transverse and longitudinal wires are fused together at their intersections through resistance welding, creating the robust structure of welded wire mesh for industry factory products. This method ensures robust, consistent welds that resist separation and deformation under stress, distinguishing it from woven mesh. The welding parameters—current, pressure, and time—are precisely calibrated for each wire gauge and material type to guarantee optimal weld strength and integrity, crucial for the longevity and reliability of the mesh.

Post-welding, the mesh undergoes rigorous quality control. This includes visual inspections for weld integrity, dimensional checks for mesh opening accuracy, and mechanical tests for tensile strength and shear resistance of the welds. Compliance with international standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials) for material properties, and ANSI (American National Standards Institute) for product specifications is non-negotiable for reputable welded wire mesh for industry manufacturers. These stringent checks ensure that the finished product meets the high performance benchmarks required for demanding industrial environments, offering a predictable service life often exceeding 20-30 years in non-corrosive conditions and 10-15 years in challenging environments, depending on material and coating. Its application across industries such as petrochemical (for safety barriers and platforms), metallurgy (for screen filtering), and water/wastewater management (for filtration and reinforcement) leverages its inherent strength and corrosion resistance, contributing significantly to energy efficiency through optimized flow or reduced material replacement needs.

Technical Parameters and Product Specifications

Selecting the appropriate welded wire mesh for industry factory applications necessitates a thorough understanding of its technical specifications. Key parameters include wire diameter, mesh opening size, material type, and surface treatment. These variables directly influence the mesh's strength, load-bearing capacity, corrosion resistance, and overall suitability for a given industrial task. Below is a comprehensive table outlining typical specifications and their relevance.

| Parameter | Description | Typical Range/Options | Industry Relevance |

|---|---|---|---|

| Material Type | Composition of wires used. | Low Carbon Steel, Stainless Steel (304, 316, 316L), Galvanized (Electro, Hot-Dipped), PVC Coated. | Determines corrosion resistance, strength, and suitability for various environments (e.g., acidic, humid). |

| Wire Diameter (Gauge) | Thickness of individual wires. | Typically 0.4mm to 6.0mm (8-27 Gauge) for general industrial use; heavier gauges for structural. | Impacts tensile strength, rigidity, and weight-bearing capacity. Larger diameter equals greater strength. |

| Mesh Opening Size (Aperture) | Distance between parallel wires. | From 6.35mm x 6.35mm (1/4 inch) up to 200mm x 200mm (8 inch); custom sizes available. | Critical for filtration, screening, safety, and aesthetic applications. Dictates flow rate or particle size. |

| Panel/Roll Width | Overall width of the mesh product. | Typically 0.5m to 2.5m (1.6 ft to 8.2 ft); custom widths possible. | Influences ease of installation and suitability for large-scale projects like fencing or flooring. |

| Panel/Roll Length | Overall length of the mesh product. | Rolls: 15m to 50m (50 ft to 164 ft). Panels: 1m to 6m (3.3 ft to 19.7 ft). | Affects logistical handling, waste minimization, and efficiency of deployment in long stretches. |

| Surface Treatment | Post-production coating for enhanced properties. | Hot-dip galvanized, electro-galvanized, PVC coated, powder coated, uncoated (for stainless). | Provides additional corrosion resistance, aesthetic appeal, and protection against abrasion or chemicals. |

Understanding these specifications is crucial for any industrial procurement process. By precisely matching the mesh parameters to the operational demands, businesses can ensure optimal performance, extended product lifespan, and enhanced safety within their facilities, ultimately leading to significant cost savings and operational efficiency, making informed decisions on their welded wire mesh for industry factory procurement.

Diverse Applications of Welded Wire Mesh in Industry

The versatility of welded wire mesh for industry factories makes it an invaluable material across a multitude of sectors. In the construction industry, it serves as reinforcement for concrete slabs, walls, and roads, providing structural integrity and preventing cracking. Its use in security fencing and machine guards is critical for worker safety and property protection in manufacturing plants and logistics hubs. Within the mining sector, heavy-duty welded mesh is used for rockfall protection, sieve screens, and support structures in underground operations, where its strength and durability are paramount.

Furthermore, the agricultural sector employs welded mesh for animal enclosures, crop protection, and general fencing. In marine and offshore environments, specialized corrosion-resistant mesh, often stainless steel or galvanized, is used for aquaculture cages, pier reinforcement, and gangways. The petrochemical and chemical processing industries benefit from its application in filtration systems, catalyst support grids, and safety platforms, where its precise mesh openings and resistance to harsh chemicals are essential. Even in consumer goods manufacturing, finer mesh is used for product displays, baskets, and shelving. This broad spectrum of applications underscores the material's adaptability and its crucial role in ensuring operational efficiency, safety, and longevity across diverse industrial landscapes, making it a staple for any welded wire mesh for industry factory project. The ability of this mesh to withstand significant loads and corrosive elements contributes directly to the overall efficiency and safety of industrial operations.

Strategic Partnerships and Customization Solutions

Recognizing that standard products may not always suffice, leading welded wire mesh for industry suppliers offer extensive customization capabilities. This includes tailoring mesh dimensions, wire gauges, material types, and coatings to meet unique project specifications. For example, a client requiring specific filtration efficiency in a chemical plant might need a precise mesh opening and a particular grade of stainless steel to resist highly corrosive substances. Similarly, a construction project might demand specialized large-format panels with integrated cutouts for utility conduits. Reputable manufacturers leverage advanced design software and production machinery to translate complex engineering drawings into high-precision mesh products.

Our company prides itself on over two decades of dedicated service in the wire mesh industry, partnering with global leaders in construction, manufacturing, and infrastructure. This extensive experience, coupled with our ISO 9001:2015 certification, ensures that every customized solution adheres to the highest standards of quality and performance. Our team of expert engineers collaborates closely with clients from conceptualization to delivery, providing technical consultation and ensuring that the final product integrates seamlessly into their operational frameworks. This commitment to bespoke solutions and unparalleled service defines our approach to being a premier provider of welded wire mesh for industry factory, fostering long-term relationships built on trust and mutual success.

Case Studies and Client Success Stories

Our dedication to delivering superior welded wire mesh for industry factories is best exemplified through our successful projects. In a recent collaboration with a major petrochemical facility in the Gulf region, we supplied custom-fabricated stainless steel welded mesh for safety gratings and elevated walkways. The challenging environment, characterized by high humidity and exposure to corrosive chemicals, necessitated material with exceptional resistance. Our SS316L mesh, specifically engineered for the project, demonstrated superior longevity and minimal maintenance requirements over the initial five years, significantly reducing the client's operational expenditure compared to their previous solutions. This project highlighted our capability to meet stringent industry standards, including specific NACE (National Association of Corrosion Engineers) recommendations for material selection.

Another notable project involved providing large quantities of galvanized welded mesh for an agricultural development in Southeast Asia, used for extensive animal fencing and crop protection against wildlife. The client reported a substantial improvement in farm security and animal containment, with the mesh enduring harsh weather conditions and exhibiting remarkable durability. Feedback consistently praises our responsiveness, the technical accuracy of our products, and our commitment to on-time delivery, underscoring our position as a trusted partner for welded wire mesh for industry factory applications globally. These real-world applications demonstrate not just the product's performance but also the value of our comprehensive service and technical support.

Frequently Asked Questions (FAQ)

Q1: What are the primary advantages of welded wire mesh over woven mesh for industrial applications?

Welded wire mesh offers superior structural rigidity and dimensional stability compared to woven mesh. Each wire intersection is permanently welded, preventing shifting or deformation, which is crucial for applications requiring precise aperture sizes or high load-bearing capacity. This makes it ideal for industrial uses like reinforcement, security barriers, and heavy-duty screening where consistency and strength are paramount for effective welded wire mesh for industry factory deployment.

Q2: How do you ensure the corrosion resistance of your welded wire mesh?

We ensure corrosion resistance through the selection of appropriate materials and surface treatments. For highly corrosive environments, we recommend stainless steel grades (e.g., SS316, SS316L). Additionally, options like hot-dip galvanization or PVC coating provide a protective barrier against rust and chemical degradation, significantly extending the lifespan of the welded wire mesh for industry factory use. Our products adhere to ASTM A123/A123M standards for galvanization, ensuring robust protection vital for the longevity of welded wire mesh for industry factory.

Q3: What is the typical lead time for custom welded wire mesh orders?

Lead times for custom welded wire mesh for industry factory products vary based on complexity, quantity, and material availability. Standard orders usually ship within 2-4 weeks, while complex custom projects might require 6-8 weeks for production and quality checks. We maintain transparent communication throughout the production process, providing regular updates and working closely with clients to meet their project timelines. Expedited options may be available upon request.

Q4: Do you offer technical support for installation or application queries?

Yes, our team of experienced engineers and technical specialists provides comprehensive support, from initial consultation to post-delivery assistance. We can offer guidance on product selection, application suitability, installation best practices, and maintenance recommendations to ensure optimal performance of our welded wire mesh for industry manufacturers' products in your specific industrial context.

Commitment to Quality, Delivery, and Customer Support

As a trusted partner for industrial operations, our commitment extends beyond merely supplying welded wire mesh for industry factory products; it encompasses a holistic approach to customer satisfaction. We guarantee stringent quality control at every stage of production, adhering to international standards such as ISO 9001 and relevant ASTM specifications. Each batch undergoes rigorous testing to ensure material integrity, weld strength, and dimensional accuracy, providing you with verifiable quality data and peace of mind. Our robust quality management system is fundamental to ensuring the long-term reliability of products used in critical industrial applications.

Understanding the critical nature of project timelines, we have optimized our logistics and supply chain to ensure reliable and efficient delivery. Our delivery protocols are designed to minimize lead times while ensuring product safety during transit. Furthermore, our products are backed by a comprehensive warranty, typically covering manufacturing defects for 5 to 10 years, depending on the material and application, demonstrating our confidence in their durability and performance. Our dedicated customer support team is available to assist with any queries, from technical specifications to order tracking, ensuring a seamless experience from inquiry to post-installation support. This unwavering commitment to excellence establishes us as a preferred choice among welded wire mesh for industry manufacturers and welded wire mesh for industry suppliers.

Conclusion

The demand for high-quality welded wire mesh for industry factory applications continues to grow, driven by the need for durable, versatile, and cost-effective material solutions across various sectors. As a critical component in everything from heavy construction to sophisticated filtration systems, its technical specifications, manufacturing precision, and robust performance are non-negotiable. Partnering with an experienced and reputable welded wire mesh for industry supplier ensures not only access to superior products but also comprehensive technical support, customization capabilities, and reliable logistics, crucial elements for successful industrial projects. Investing in quality welded wire mesh is an investment in the long-term integrity, safety, and efficiency of your industrial operations.

References

- American Society for Testing and Materials (ASTM) Standards for Steel Reinforcement and Wire Products.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- NACE International (formerly National Association of Corrosion Engineers) Corrosion Engineering Handbook.

- Construction Industry Institute (CII) Best Practices for Industrial Project Material Procurement.

- Journal of Materials Science and Engineering: A - Structural Materials Properties, Microstructure and Processing.

- Metals Handbook, Desk Edition - Properties and Selection: Nonferrous Alloys and Special-Purpose Materials.

-

Chain Link Fence - Anping County Puersen | Durability&Customization

NewsAug.11,2025

-

High-Quality Welded Wire Mesh for Industry Factory Direct

NewsAug.11,2025

-

Galvanized Steel Fence Factory | Durable, Versatile, Reliable

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen | Durability, Flexibility, Cost-Effective

NewsAug.11,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.11,2025

-

Chain Link Fence - Anping County Puersen Hardware Wire Mesh Products Co., Ltd | Durable Security, Versatile Application

NewsAug.10,2025