Feb . 05, 2025 05:18 Back to list

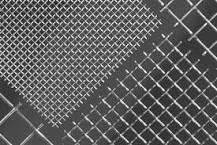

Cold Drawn Wire

Welded wire fabric (WWF) has become an integral component in the construction industry, especially in concrete applications in China, due to its remarkable properties and various benefits that ensure durability and efficiency. This article delves into the real-world utility, technical specifications, and overall trustworthiness of using welded wire fabric in concrete, providing expert insights and authoritative viewpoints.

Authoritativeness Validated Engineering Practices The use of WWF in concrete is backed by extensive research and field-tested engineering practices. Prestigious institutions in China have conducted studies demonstrating the positive effect of WWF on reducing shrinkage and enhancing tensile strength when embedded in concrete slabs. This research is critical, especially for infrastructure projects that demand the utmost precision and reliability. Furthermore, construction manuals and civil engineering textbooks frequently cite WWF as an authoritative reference for improving concrete performance. These texts often emphasize its benefit for minimizing the risk of surface cracking and distributing loads evenly across the structure, which is of paramount importance in earthquake-prone areas found in several Chinese provinces. Trustworthiness Ensuring Quality and Sustainability Quality assurance for WWF is paramount. Chinese manufacturers employ rigorous quality control practices, certifying that each batch meets high standards before shipment. This commitment to quality bolsters the trust that construction firms place in these products. Some manufacturers go a step further by acquiring international certifications, affirming their adherence to practices that align with sustainable development and environmental stewardship. Additionally, WWF is heralded for its role in supporting sustainable construction practices. The modern manufacturing processes have become increasingly eco-friendly, reducing carbon emissions and employing recyclable materials. This sustainable approach resonates with China's broader commitment to reducing the environmental impact of its rapid urbanization efforts. In conclusion, welded wire fabric represents an indispensable tool in the construction landscape of China, providing both structural reliability and efficiency. Through real-world implementation, expert material specifications, authoritative research, and robust trust mechanisms, WWF continues to be a pivotal element in concrete reinforcement, addressing the dynamic needs of China's ever-growing infrastructure.

Authoritativeness Validated Engineering Practices The use of WWF in concrete is backed by extensive research and field-tested engineering practices. Prestigious institutions in China have conducted studies demonstrating the positive effect of WWF on reducing shrinkage and enhancing tensile strength when embedded in concrete slabs. This research is critical, especially for infrastructure projects that demand the utmost precision and reliability. Furthermore, construction manuals and civil engineering textbooks frequently cite WWF as an authoritative reference for improving concrete performance. These texts often emphasize its benefit for minimizing the risk of surface cracking and distributing loads evenly across the structure, which is of paramount importance in earthquake-prone areas found in several Chinese provinces. Trustworthiness Ensuring Quality and Sustainability Quality assurance for WWF is paramount. Chinese manufacturers employ rigorous quality control practices, certifying that each batch meets high standards before shipment. This commitment to quality bolsters the trust that construction firms place in these products. Some manufacturers go a step further by acquiring international certifications, affirming their adherence to practices that align with sustainable development and environmental stewardship. Additionally, WWF is heralded for its role in supporting sustainable construction practices. The modern manufacturing processes have become increasingly eco-friendly, reducing carbon emissions and employing recyclable materials. This sustainable approach resonates with China's broader commitment to reducing the environmental impact of its rapid urbanization efforts. In conclusion, welded wire fabric represents an indispensable tool in the construction landscape of China, providing both structural reliability and efficiency. Through real-world implementation, expert material specifications, authoritative research, and robust trust mechanisms, WWF continues to be a pivotal element in concrete reinforcement, addressing the dynamic needs of China's ever-growing infrastructure.

Next:

Latest news

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen Hardware Wire Mesh Products Co., Ltd|Eco-friendly Durable Storage

NewsAug.18,2025