ສ.ຫ. . 23, 2025 01:40 Back to list

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

Strategic Applications of Welded Wire Mesh in Modern Industrial Facilities

In the intricate landscape of B2B industrial operations, the selection of foundational materials is paramount to achieving structural integrity, operational efficiency, and long-term durability. Among these, welded wire mesh for industry factory applications stands out as a versatile and indispensable component. This robust material, engineered for diverse industrial environments, provides a critical framework for everything from safety enclosures and structural reinforcement to filtration systems and security perimeters. Understanding its technical nuances, manufacturing precision, and strategic deployment is essential for decision-makers in demanding sectors such as petrochemicals, mining, construction, and power generation. This article delves into the core aspects of modern welded wire mesh, detailing its production, technical specifications, diverse applications, and the competitive advantages it offers, ensuring informed procurement and optimized operational outcomes for industrial enterprises.

Contemporary Industry Trends in Welded Wire Mesh Deployment

The global industrial landscape is continuously evolving, driving demand for materials that offer enhanced performance, sustainability, and cost-effectiveness. For welded wire mesh for industry factories, key trends include:

- Sustainable Manufacturing Practices: Increasing emphasis on eco-friendly production, including the use of recycled steel and energy-efficient welding processes, minimizing environmental impact.

- Advanced Corrosion Protection: Development of superior coating technologies, such as highly durable PVC coatings and specialized galvanization techniques (e.g., hot-dip after welding), to extend service life in aggressive industrial environments.

- Automation and Precision: Greater adoption of automated welding machines and robotic systems ensures consistent mesh quality, tighter tolerances, and increased production efficiency, reducing human error.

- Smart Mesh Solutions: Emerging interest in incorporating sensor technologies within mesh structures for structural health monitoring, particularly in critical infrastructure applications.

- Customization and Modularity: Growing demand for tailor-made mesh solutions that perfectly fit specific project requirements, reducing waste and installation time. Manufacturers are investing in flexible production lines to meet these bespoke needs.

These trends reflect a broader industry move towards intelligent, robust, and environmentally responsible material solutions.

Detailed Manufacturing Process Flow for Welded Wire Mesh

The production of welded wire mesh for industry manufacturers involves a meticulously controlled multi-stage process to ensure product integrity and performance. This process primarily focuses on drawing high-quality wire and then fusing these wires into a robust grid structure. While some industrial components might involve casting, forging, or CNC machining, the core of wire mesh production is precision welding.

- Raw Material Selection: High-grade steel wire rods (e.g., low carbon steel, stainless steel grades 304/316, galvanized steel) are selected based on the end application's requirements for strength, corrosion resistance, and ductility. Material certifications (e.g., ASTM A82, EN 10016-2) are verified.

- Wire Drawing: The raw wire rods are drawn through a series of dies to achieve the precise wire diameter required for the mesh. This process enhances the wire's tensile strength and improves surface finish.

- Straightening and Cutting: The drawn wires are then precisely straightened and cut to specific lengths, forming both the line wires (longitudinal) and cross wires (transverse) of the mesh.

- Automated Resistance Welding: The core of the process. Line wires are fed continuously, while cross wires are intermittently positioned perpendicular to them. High-current electrical resistance welding is applied at each intersection, fusing the wires together without the need for filler material. Modern machines utilize Programmable Logic Controllers (PLCs) for precise spacing and consistent weld strength, adhering to standards like AWS D1.4.

-

Surface Treatment (Post-Welding):

- Hot-Dip Galvanizing: For superior corrosion resistance, the welded mesh panels are immersed in molten zinc. This creates a metallurgical bond, providing a thick, durable coating (conforming to ISO 1461, ASTM A123).

- PVC Coating: For enhanced aesthetic appeal, UV resistance, and additional corrosion protection, a layer of polyvinyl chloride (PVC) can be applied over galvanized mesh.

- Electrolytic Galvanizing: A thinner, aesthetically uniform zinc coating, often applied before welding for finer mesh.

-

Quality Control and Testing: Each batch undergoes rigorous testing.

- Weld Shear Strength Test: Ensures each weld can withstand specified loads (e.g., minimum 70% of the wire's tensile strength).

- Dimensional Accuracy: Verification of mesh opening size, wire diameter, and panel dimensions.

- Coating Thickness Test: For galvanized and PVC-coated meshes (e.g., using eddy current or magnetic gauges).

- Material Composition Analysis: Spectrometric analysis to confirm raw material specifications.

- Adherence to Standards: Compliance with international standards such as ISO 9001 (Quality Management), ASTM A185/A497 (for concrete reinforcement), and relevant national standards.

- Finishing and Packaging: Finished mesh panels or rolls are trimmed, inspected, and packaged according to customer specifications for safe transport and storage.

The typical service life for a standard galvanized welded wire mesh can range from 15 to 30 years, depending on environmental conditions and coating thickness, while stainless steel variants offer even longer lifespans, often exceeding 50 years with minimal maintenance.

Schematic representation of the precision welding process for industrial mesh.

Key Technical Specifications of Industrial Welded Wire Mesh

The performance of welded wire mesh for industry factory applications is critically dependent on its precise technical specifications. Engineers and procurement specialists must consider these parameters to ensure the mesh meets structural, safety, and operational demands.

Standard Product Specification Table

| Parameter | Specification Range (Typical) | Relevant Standard |

|---|---|---|

| Material Grade | Low Carbon Steel (Q195/Q235), Stainless Steel (304, 316), Galvanized Steel | ASTM A82/A185, EN 10016-2 |

| Wire Diameter | 0.8 mm – 12.0 mm (0.031" – 0.472") | ASTM A82, BS 4482 |

| Mesh Opening (Square/Rectangular) | 6x6 mm – 200x200 mm (0.24"x0.24" – 7.87"x7.87") | ISO 9044, ASTM A185 |

| Panel Width | 0.5 m – 3.0 m (1.64 ft – 9.84 ft) | Customizable |

| Panel Length | 1.0 m – 6.0 m (3.28 ft – 19.68 ft) | Customizable |

| Surface Treatment | Untreated, Electro-Galvanized, Hot-Dip Galvanized, PVC Coated | ISO 1461, ASTM A123, EN 10244-2 |

| Tensile Strength (for Low Carbon Steel) | 450-550 MPa (65-80 ksi) | ASTM E8/A370 |

| Yield Strength (for Low Carbon Steel) | 350-450 MPa (50-65 ksi) | ASTM E8/A370 |

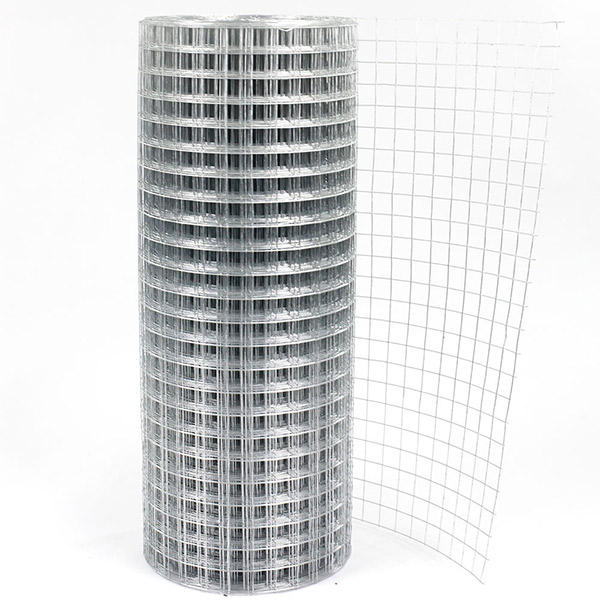

A selection of industrial welded wire mesh panels showcasing various mesh sizes and wire gauges.

These specifications are critical for engineers designing structures or systems where welded wire mesh for industry factory components are integral. Understanding the interplay between wire diameter, mesh opening, material grade, and surface treatment ensures optimal performance, particularly in demanding conditions requiring high strength, chemical resistance, or specific filtration capabilities.

Diverse Application Scenarios and Target Industries

The inherent strength, versatility, and customizability of welded wire mesh for industry suppliers make it an invaluable material across a multitude of sectors. Its applications extend far beyond simple fencing, playing critical roles in structural integrity, safety, and operational processes.

- Petrochemical Industry: Used extensively for grating, walkways, safety barriers, and filtration screens in refineries, chemical plants, and offshore platforms. The corrosion resistance of stainless steel or specially coated mesh is crucial here to withstand harsh chemical exposures.

- Metallurgy and Mining: Employed in screening and sorting operations for ores and aggregates, machine guarding, and reinforcing rock faces in underground mines. Heavy-gauge, high-tensile mesh provides durability against abrasive materials and impact.

- Water Supply & Drainage: Critical for intake screens, filter media support, and sediment control in water treatment plants, municipal drainage systems, and wastewater management facilities. Stainless steel variants excel in preventing biofouling and maintaining structural integrity in submerged conditions.

- Construction and Infrastructure: Primary use as concrete reinforcement (e.g., in foundations, slabs, precast elements) due to its high tensile strength and uniform stress distribution. Also used for gabions in erosion control, security fencing, and pedestrian barriers.

- Power Generation (Conventional & Renewable): Safety enclosures for equipment, ventilation screens, bird-proofing, and structural support within power plants, solar farms, and wind energy installations. Flame-retardant coatings can be specified for enhanced safety.

- Agriculture and Aquaculture: Enclosures for livestock, crop protection, and construction of aquaculture cages where corrosion resistance in saline environments is paramount.

Welded wire mesh deployed as a robust safety barrier in an industrial setting.

In each of these sectors, the selection of the correct mesh type—considering wire diameter, mesh opening, material, and surface finish—is paramount to ensure optimal performance, safety, and longevity.

Technical Advantages of Welded Wire Mesh

The widespread adoption of welded wire mesh for industry factory applications is underpinned by a compelling set of technical advantages that directly contribute to operational efficiency, safety, and structural integrity.

- Superior Structural Integrity: Each intersection of the wires is individually welded, creating a strong, rigid panel that maintains its shape and dimensions under load. This contrasts with woven mesh, which can distort under stress. This provides excellent tensile strength and load-bearing capacity, particularly vital for concrete reinforcement or heavy-duty screening.

- Enhanced Corrosion Resistance: With options for hot-dip galvanization (minimum 600 g/m² zinc coating, ISO 1461) or stainless steel (grades 304, 316), the mesh offers exceptional resistance to rust, oxidation, and chemical degradation, extending its service life in harsh industrial environments. PVC coating further enhances this protection and offers UV stability.

- Precision and Uniformity: Manufactured using automated processes, welded wire mesh features consistent mesh openings and wire diameters, ensuring predictable performance for filtration, screening, and dimensional accuracy for structural applications. This uniformity is crucial for adherence to engineering specifications.

- High Strength-to-Weight Ratio: Despite its robustness, welded wire mesh offers a favorable strength-to-weight ratio, which simplifies handling, reduces structural load in composite applications, and can lower transportation costs.

- Ease of Fabrication and Installation: Panels can be easily cut, bent, and shaped on-site or pre-fabricated to specific dimensions, significantly reducing installation time and labor costs compared to alternative materials. Its rigidity also aids in stable handling.

- Cost-Effectiveness and Reduced Maintenance: The long service life due to robust construction and protective coatings translates into lower lifecycle costs and reduced maintenance requirements, offering substantial long-term savings for industrial operations.

These advantages collectively contribute to a material solution that is not only reliable but also economically viable for a broad spectrum of demanding industrial applications.

Vendor Comparison: Selecting the Right Welded Wire Mesh Partner

Choosing the appropriate supplier for welded wire mesh for industry factory needs is a critical decision that impacts project timelines, material quality, and overall cost-effectiveness. A thorough evaluation of potential vendors based on several key criteria is essential.

Key Evaluation Criteria for Welded Wire Mesh Suppliers

| Criterion | Description & Importance | Vendor A (Example) | Vendor B (Example) |

|---|---|---|---|

| Certifications & Standards | Adherence to ISO 9001, ASTM, EN standards ensures quality management and product compliance. | ISO 9001, ASTM A185/A497, 25 years in service. | ISO 9001, limited ASTM compliance. |

| Customization Capabilities | Ability to produce bespoke mesh sizes, wire diameters, materials, and coatings for unique project requirements. | Extensive custom fabrication, dedicated engineering team. | Standard products, limited customization. |

| Material Quality & Sourcing | Transparency in raw material sourcing and quality control ensures durability and performance. | Premium European/North American steel, verifiable MTCs. | Mixed global sourcing, MTCs upon request. |

| Lead Time & Logistics | Reliable production schedules and efficient global logistics for timely delivery. | Standard 2-4 weeks, expedited options, global shipping network. | Standard 4-6 weeks, regional delivery. |

| Technical Support & After-Sales | Availability of engineering support, installation guidance, and warranty. | 24/7 technical hotline, 10-year warranty on galvanized mesh. | Business hours support, 5-year limited warranty. |

| Pricing & Value Proposition | Competitive pricing coupled with superior quality, service, and long-term cost savings. | Premium pricing, but excellent lifecycle cost. | Lower upfront cost, potential higher long-term maintenance. |

Quality control inspection of a welded wire mesh panel for industrial applications.

By meticulously comparing vendors against these metrics, industrial clients can secure a partnership that guarantees the highest quality welded wire mesh for industry factory projects, ensuring reliability and compliance for their critical applications.

Customized Solutions and Bespoke Manufacturing

While standard welded wire mesh for industry factory products serve a broad range of applications, many industrial projects necessitate bespoke solutions tailored to unique operational demands or site-specific constraints. Reputable manufacturers offer extensive customization capabilities to address these specialized requirements.

- Tailored Dimensions: Precise control over panel width and length, allowing for seamless integration into existing structures or complex designs, minimizing waste and onsite fabrication.

- Variable Mesh Openings and Wire Gauges: The ability to specify non-standard mesh apertures (e.g., elongated rectangles, varying square sizes) and wire diameters ensures optimal strength, flow characteristics, or security levels for specific applications like specialized filtration or high-impact protection.

- Specialty Materials and Coatings: Beyond standard galvanized or stainless steel, customization can include specific alloys for extreme temperature resistance, chemical inertness, or specialized coatings for anti-static properties, anti-microbial surfaces, or unique color requirements (e.g., RAL colors for PVC coating).

- Integrated Fabrication: Some suppliers offer secondary fabrication services, such as bending, rolling, cutting to complex shapes, or adding mounting points, which simplifies installation for the client and ensures a perfect fit.

- Engineering Design Support: Reputable manufacturers provide technical consultation and engineering design services to help clients define optimal mesh specifications, perform stress analyses, and ensure compliance with relevant industry codes and safety standards.

Engaging with a manufacturer capable of delivering comprehensive customized solutions ensures that the welded wire mesh precisely meets the functional, environmental, and regulatory demands of even the most challenging industrial projects.

Application Case Studies: Welded Wire Mesh in Action

The practical utility and robust performance of welded wire mesh are best illustrated through real-world applications where it has provided critical solutions and demonstrated long-term value.

Case Study 1: Heavy Machinery Guarding in Automotive Manufacturing

A leading automotive manufacturer required robust safety guarding for its automated assembly lines and robotic work cells. Traditional solid barriers obstructed visibility and ventilation. High-strength, hot-dip galvanized welded wire mesh for industry factory panels (50x50mm mesh, 4.0mm wire diameter) were specified. These panels offered excellent impact resistance, allowed visual monitoring of operations, and facilitated air circulation, contributing to a safer and more efficient production environment. The quick installation due to pre-fabricated modular panels minimized downtime during facility upgrades.

Case Study 2: Erosion Control for a Major Pipeline Project

A large-scale energy infrastructure project involved the construction of a natural gas pipeline through varied terrain, including steep embankments susceptible to erosion. Gabion baskets fabricated from heavy-gauge, PVC-coated galvanized welded wire mesh were deployed. Filled with local stone, these gabions provided a flexible, permeable, and environmentally friendly solution for retaining soil, stabilizing slopes, and preventing erosion around the pipeline route. The PVC coating ensured decades of service life in corrosive soil conditions.

Case Study 3: Advanced Filtration in a Chemical Processing Plant

A chemical plant needed robust internal filtration media support grids for its reactors and separation columns. The environment involved highly corrosive acids and elevated temperatures. Custom-fabricated welded wire mesh for industry factories from Stainless Steel 316L (20x20mm mesh, 2.5mm wire diameter), with electropolished finish, was chosen. The precise and stable mesh structure offered reliable support for the filter media, while the 316L stainless steel provided superior resistance to chemical attack, drastically extending the lifespan of the filtration system and reducing maintenance cycles.

Welded wire mesh used for security and containment in an industrial complex.

Quality Assurance, Certifications, and Long-Term Reliability

For industrial applications, the reliability and longevity of welded wire mesh for industry factory are non-negotiable. Reputable manufacturers adhere to stringent quality assurance protocols and possess industry-recognized certifications, underpinning product trust and authoritativeness.

- ISO 9001 Certification: This international standard for quality management systems ensures consistent product quality, from raw material procurement to final inspection and delivery. A certified manufacturer demonstrates a commitment to continuous improvement and customer satisfaction.

- Adherence to Industry Standards: Compliance with specific standards like ASTM A185/A497 (for concrete reinforcement), EN 10244-2 (for zinc coatings), and various national building codes, confirms that the mesh meets the rigorous demands of engineering and construction.

- Comprehensive Testing: Manufacturers conduct in-house and third-party testing, including tensile strength tests, weld shear strength tests (e.g., meeting requirements of minimum 250 N/mm² shear capacity for structural applications), chemical composition analysis, and coating thickness measurements. Detailed test reports and Material Test Certificates (MTCs) are provided.

- Proven Track Record and Partnerships: Years of experience in serving critical industries and long-standing relationships with major industrial clients and contractors attest to a manufacturer's reliability and expertise.

These commitments to quality and verifiable standards provide industrial buyers with the confidence that their investment in welded wire mesh will yield durable and high-performing results.

Frequently Asked Questions (FAQ)

- Q1: What is the primary difference between welded and woven wire mesh?

- A1: Welded wire mesh has wires fused at each intersection by resistance welding, providing a rigid, dimensionally stable structure. Woven mesh has wires interlaced, offering flexibility but potentially less stability under specific loads. Welded mesh is preferred for structural integrity and precise apertures.

- Q2: How do I choose the correct surface treatment for my application?

- A2: The choice depends on the environmental conditions. Untreated mesh is for indoor, dry environments. Electro-galvanized offers basic rust resistance. Hot-dip galvanized provides superior corrosion protection for outdoor or humid conditions. PVC coating offers enhanced corrosion and UV resistance, often used for aesthetic or chemical resistance needs. Stainless steel (304, 316) is for highly corrosive, high-temperature, or hygienic environments.

- Q3: Can welded wire mesh for industry factory applications be customized?

- A3: Yes, most reputable manufacturers offer extensive customization. This includes specific wire diameters, mesh openings, panel dimensions, material grades, and surface finishes. Providing detailed engineering specifications ensures the production of a bespoke product tailored to your exact project needs.

- Q4: What is the typical lead time for large orders of welded wire mesh?

- A4: Lead times vary based on order volume, customization complexity, and current production schedules. For standard products, it typically ranges from 2 to 4 weeks. For highly customized or very large orders, it can extend to 6-8 weeks or more. We recommend consulting directly with our sales team for precise lead time estimates based on your specific requirements.

Logistics, Warranty, and Customer Support

Ensuring a seamless procurement experience for welded wire mesh for industry factory projects extends beyond product quality to efficient logistics, robust warranties, and reliable customer support.

- Lead Time & Fulfillment: We maintain efficient production lines and strategic raw material stockpiles to ensure competitive lead times. Standard orders are typically fulfilled within 2-4 weeks. For expedited requirements or large-scale projects, dedicated project managers work to optimize production and logistics to meet tight deadlines. Our global logistics network ensures reliable and timely delivery worldwide.

- Warranty Commitments: Our welded wire mesh products are backed by comprehensive warranties that reflect our confidence in their quality and durability. For hot-dip galvanized mesh, we offer a 10-year anti-corrosion warranty under normal industrial operating conditions. Stainless steel products typically carry a 20-year material defect warranty. Specific warranty details are provided with each order and project specification.

- Dedicated Customer Support: Our expert technical support team is available from project conception through installation and beyond. We provide engineering consultation, detailed product documentation, installation guides, and prompt assistance for any queries or challenges. Contact us via phone, email, or our dedicated online portal for swift and professional support.

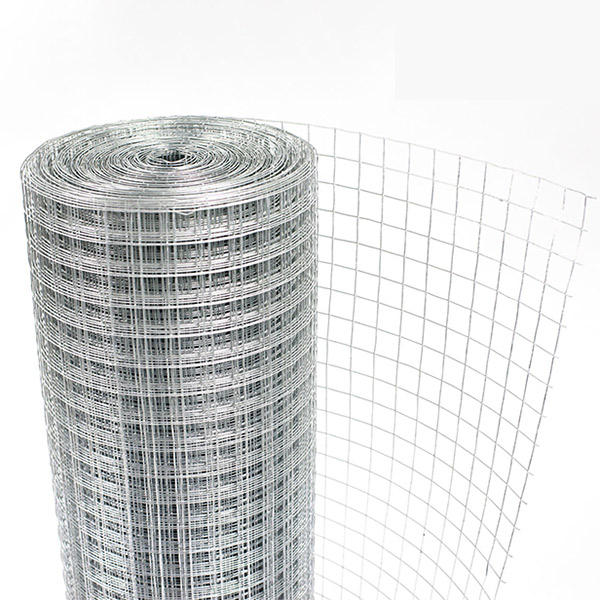

Secure packaging of welded wire mesh rolls for global industrial distribution.

Our commitment to a holistic service experience ensures that our clients receive not just a product, but a complete solution supported by expertise, reliability, and dedicated care.

Conclusion: The Indispensable Role of Welded Wire Mesh

The strategic deployment of high-quality welded wire mesh for industry factory applications is fundamental to the operational success, safety, and longevity of modern industrial facilities. From its precision manufacturing through advanced resistance welding, adherence to stringent international standards, and diverse applications across petrochemicals, mining, and construction, welded wire mesh offers unmatched structural integrity, corrosion resistance, and adaptability. By partnering with experienced manufacturers who prioritize technical excellence, customization, and comprehensive support, industrial decision-makers can leverage this versatile material to optimize their operations, enhance safety protocols, and ensure robust, long-lasting infrastructure. As industries continue to evolve, the demand for reliable, high-performance materials like welded wire mesh will only grow, cementing its role as an indispensable component in the industrial toolkit.

References

- American Society for Testing and Materials (ASTM). ASTM A185/A185M - 20a: Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete. ASTM International, West Conshohocken, PA.

- International Organization for Standardization (ISO). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. ISO, Geneva, Switzerland.

- British Standards Institution (BSI). BS EN 10244-2: Steel wire and wire products. Non-ferrous metallic coatings on steel wire. Zinc or zinc alloy coatings. BSI, London, UK.

- American Welding Society (AWS). AWS D1.4/D1.4M: Structural Welding Code – Reinforcing Steel. AWS, Miami, FL.

- Eurocode 2: Design of concrete structures – Part 1-1: General rules and rules for buildings (EN 1992-1-1). European Committee for Standardization (CEN), Brussels, Belgium.

This is the last article

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025

-

Your Galvanized Steel Fence Factory - Strong, Durable Solutions

NewsAug.22,2025

-

Welded Wire Mesh for Industry: Factory Direct & Custom Solutions

NewsAug.21,2025

-

Welded Wire Mesh for Industry | Factory Direct & Durable Solutions

NewsAug.19,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Co., Ltd.|Durable Security&Versatile Applications

NewsAug.18,2025

-

Glass Food Storage Jar with Screw Wooden Lid - Anping County Puersen|Heat-Resistant & BPA Free

NewsAug.18,2025