ກ.ຍ. . 21, 2024 11:50 Back to list

twisted bars for grating welding suppliers

Twisted Bars for Grating Welding Suppliers Enhancing Structural Integrity

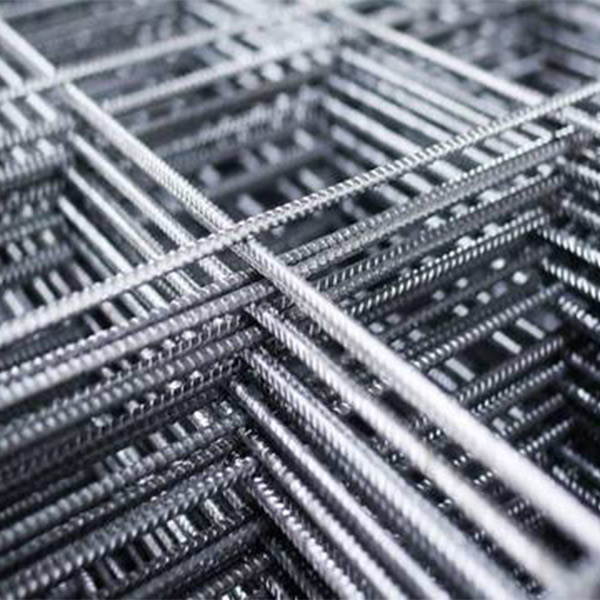

In the construction and manufacturing industries, the strength and durability of structural elements are paramount. Twisted bars, commonly utilized in grating welding, have emerged as a preferred choice among suppliers due to their structural advantages and versatility. This article delves into the significance of twisted bars in grating welding, highlighting the benefits they offer to suppliers and end-users alike.

Twisted bars, characterized by their helical design, provide enhanced tensile strength and resistance to deformation. This unique shape allows them to distribute loads more evenly compared to traditional straight bars. As a result, twisted bars minimize the risk of structural failure, making them ideal for applications where safety and stability are non-negotiable. Suppliers who specialize in grating welding can leverage these advantages to offer superior products that meet stringent industry standards.

One major benefit of using twisted bars in grating welding is their improved adhesion during the welding process. The twisted design increases the surface area that comes into contact with the weld, promoting a stronger bond between the bars and the grating materials. This characteristic is vital in ensuring that the final product can withstand dynamic loads and adverse environmental conditions, which are common in many industrial applications.

twisted bars for grating welding suppliers

Furthermore, twisted bars are often lighter than traditional reinforcement materials, which can lead to reduced shipping costs and easier handling during installation. Suppliers can capitalize on this advantage, providing their clients with an economically viable solution that does not compromise on quality. This is particularly appealing to construction companies seeking to optimize resource allocation while maintaining structural integrity.

The demand for twisted bars in grating welding applications continues to grow. As industries strive to enhance safety and efficiency, suppliers are presented with significant opportunities to innovate and expand their product offerings. By focusing on the production and supply of high-quality twisted bars, suppliers can position themselves as leaders in the market, attracting a broader customer base.

In conclusion, twisted bars are a vital component for grating welding suppliers looking to enhance the quality and performance of their products. Their unique design offers numerous benefits, including improved strength, better adhesion, and lightweight properties. As industries evolve and demand for robust structural solutions increases, suppliers who prioritize twisted bars in their offerings will undoubtedly secure a competitive edge in the manufacturing landscape. Embracing this innovation is essential for suppliers aiming to meet the changing needs of their clients while promoting safety and efficiency in construction and manufacturing processes.

-

Welded Wire Mesh for Industry Factory - Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.29,2025

-

Welded Wire Mesh for Industry Factory | Durable & Cost-Effective Solutions

NewsAug.29,2025

-

Durable Welded Wire Mesh for Industry Factory | Custom Solutions

NewsAug.27,2025

-

Durable Welded Wire Mesh for Industry Factory - High Quality

NewsAug.26,2025

-

Leading Galvanized Steel Fence Factory | Durable & Secure Fencing

NewsAug.24,2025

-

Welded Wire Mesh for Industry Factory - Durable & Custom Solutions

NewsAug.23,2025