Mar . 04, 2025 07:41 Back to list

welded wire mesh for industry factories

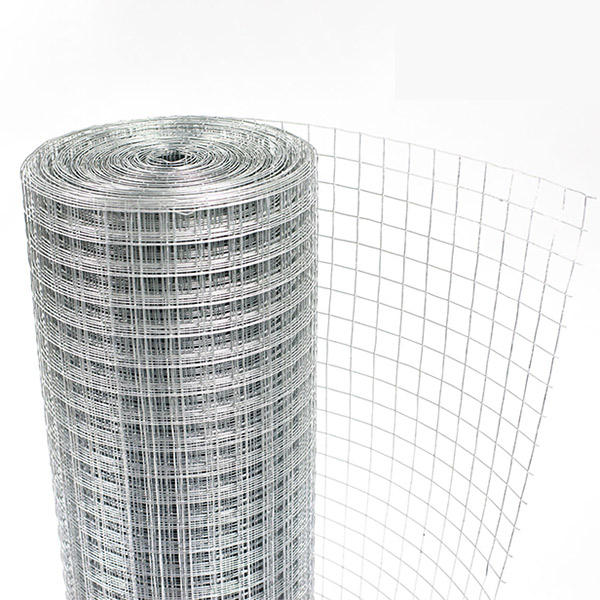

The world of construction and industrial projects often demands materials that boast durability and flexibility. Among such materials, galvanized welded mesh stands as a prime choice. This article delves into the nuances of OEM galvanized welded mesh, highlighting its characteristics, applications, and why it is the preferred option among industry specialists.

Another significant advantage of using OEM galvanized welded mesh lies in its environmental and safety benefits. Given the increasing focus on sustainable practices, the materials used in its manufacture are recyclable and contribute to reducing waste in industrial processes. Moreover, the mesh’s non-toxic nature and lack of sharp edges increase safety for workers handling the material. A key factor contributing to the authority of galvanized welded mesh within the industry is its compliance with international safety and construction standards. Manufacturers of OEM galvanized welded mesh typically adhere to stringent quality control measures, ensuring each mesh batch meets the expected performance and safety criteria. This adherence not only underscores the mesh’s reliability but also cements its status as a trusted material in significant projects worldwide. Professionals in the construction and agricultural sectors consistently attest to the efficacy and reliability of galvanized welded mesh. Their real-world experiences corroborate the product's advertised benefits, from easy installation to enduring resistance under extreme conditions. Furthermore, expert reviews emphasize how investing in OEM galvanization pays off, especially in projects demanding high durability and bespoke specifications. The expertise required to manufacture and supply high-quality OEM galvanized welded mesh is not ubiquitous. It involves a thorough understanding of metallurgical processes, precision engineering, and an acute awareness of market needs. Companies that excel in producing these meshes often have decades of experience, which is evident in their capability to deliver products that conform to the strictest of standards. In conclusion, OEM galvanized welded mesh stands as a testament to innovation and adaptability in material engineering. Its role in construction and agriculture is indispensable, offering solutions that are not only cost-effective but also adjustable to diverse project needs. When selected for its suitability to specific applications, galvanized welded mesh showcases the harmony between advanced technology and practical application, making it a material that is seen not only as useful but essential in today's fast-paced industrial landscape.

Another significant advantage of using OEM galvanized welded mesh lies in its environmental and safety benefits. Given the increasing focus on sustainable practices, the materials used in its manufacture are recyclable and contribute to reducing waste in industrial processes. Moreover, the mesh’s non-toxic nature and lack of sharp edges increase safety for workers handling the material. A key factor contributing to the authority of galvanized welded mesh within the industry is its compliance with international safety and construction standards. Manufacturers of OEM galvanized welded mesh typically adhere to stringent quality control measures, ensuring each mesh batch meets the expected performance and safety criteria. This adherence not only underscores the mesh’s reliability but also cements its status as a trusted material in significant projects worldwide. Professionals in the construction and agricultural sectors consistently attest to the efficacy and reliability of galvanized welded mesh. Their real-world experiences corroborate the product's advertised benefits, from easy installation to enduring resistance under extreme conditions. Furthermore, expert reviews emphasize how investing in OEM galvanization pays off, especially in projects demanding high durability and bespoke specifications. The expertise required to manufacture and supply high-quality OEM galvanized welded mesh is not ubiquitous. It involves a thorough understanding of metallurgical processes, precision engineering, and an acute awareness of market needs. Companies that excel in producing these meshes often have decades of experience, which is evident in their capability to deliver products that conform to the strictest of standards. In conclusion, OEM galvanized welded mesh stands as a testament to innovation and adaptability in material engineering. Its role in construction and agriculture is indispensable, offering solutions that are not only cost-effective but also adjustable to diverse project needs. When selected for its suitability to specific applications, galvanized welded mesh showcases the harmony between advanced technology and practical application, making it a material that is seen not only as useful but essential in today's fast-paced industrial landscape.

Latest news

-

Durable Welded Wire Mesh for Industry Factory | Top Quality

NewsAug.06,2025

-

Chain Link Fence: Durable Security Solutions | Anping County Puersen Hardware Wire Mesh Products Co., Ltd.

NewsAug.05,2025

-

Chain Link Fence-Durable, Versatile, Reliable|Galvanized Steel,PVC Coated

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen|Galvanized Steel, Durability, Custom Solutions

NewsAug.05,2025

-

Chain Link Fence-Anping County Puersen Hardware Wire Mesh Products Co., Ltd.|Durable&Versatile

NewsAug.05,2025

-

Welded Wire Mesh for Industrial Factories: Durable & Strong

NewsAug.05,2025